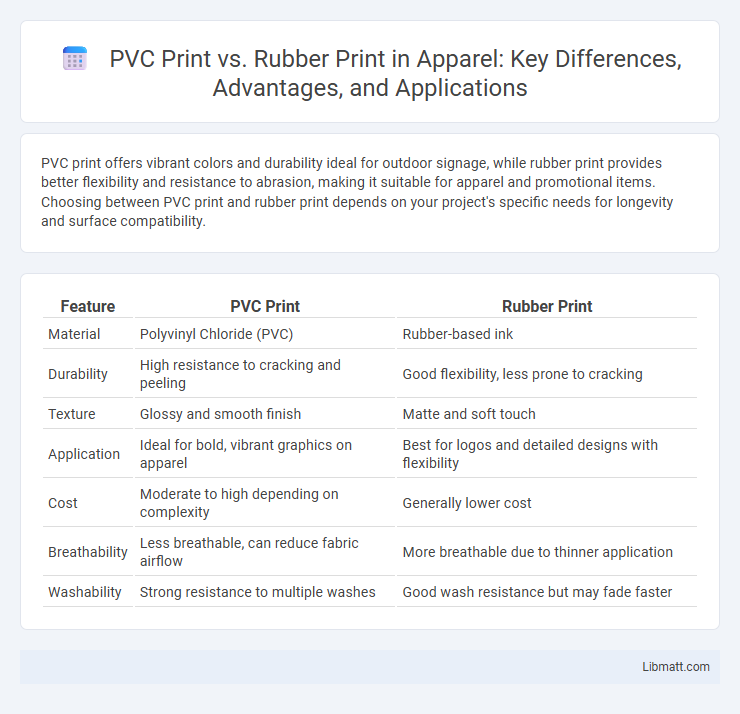

PVC print offers vibrant colors and durability ideal for outdoor signage, while rubber print provides better flexibility and resistance to abrasion, making it suitable for apparel and promotional items. Choosing between PVC print and rubber print depends on your project's specific needs for longevity and surface compatibility.

Table of Comparison

| Feature | PVC Print | Rubber Print |

|---|---|---|

| Material | Polyvinyl Chloride (PVC) | Rubber-based ink |

| Durability | High resistance to cracking and peeling | Good flexibility, less prone to cracking |

| Texture | Glossy and smooth finish | Matte and soft touch |

| Application | Ideal for bold, vibrant graphics on apparel | Best for logos and detailed designs with flexibility |

| Cost | Moderate to high depending on complexity | Generally lower cost |

| Breathability | Less breathable, can reduce fabric airflow | More breathable due to thinner application |

| Washability | Strong resistance to multiple washes | Good wash resistance but may fade faster |

Introduction to Fabric Printing Techniques

PVC print offers vibrant, durable designs with a glossy finish, making it ideal for bold, long-lasting graphics on fabrics. Rubber print provides a softer, matte texture that ensures flexibility and comfort, perfect for garments that require breathability and stretch. Your choice depends on whether you prioritize vivid visuals or tactile comfort in fabric printing techniques.

What is PVC Print?

PVC Print involves using polyvinyl chloride material to create vibrant, durable designs ideal for signage, labels, and promotional items. This printing method offers waterproof and UV-resistant qualities, making it suitable for both indoor and outdoor applications. Your choice of PVC Print ensures long-lasting visibility and high-quality color reproduction.

What is Rubber Print?

Rubber print refers to a printing technique that uses a rubber-based ink or material to create durable and flexible designs on various surfaces, such as textiles and promotional items. Unlike PVC print, which involves a rigid polyvinyl chloride layer, rubber print offers enhanced stretchability and resistance to cracking, making it ideal for garments that require flexibility. Its eco-friendliness and breathable properties also contribute to its popularity in custom apparel printing.

Key Differences Between PVC Print and Rubber Print

PVC print offers high durability and vibrant color reproduction, making it ideal for detailed graphics and long-lasting outdoor signage. Rubber print excels in flexibility, tactile texture, and resistance to abrasion, often preferred for applications requiring a softer, more resilient surface like footwear or protective gear. Choosing between PVC print and rubber print depends on Your need for either vivid, rigid prints or flexible, durable materials suited to specific functional uses.

Durability: PVC vs Rubber Print

PVC print offers superior durability by resisting water, UV rays, and abrasion, making it ideal for long-term outdoor applications. Rubber print, while flexible and resilient, tends to degrade faster under harsh weather conditions and heavy wear. PVC's robust material composition ensures longer-lasting quality compared to the more vulnerable rubber print.

Visual Finish and Texture Comparison

PVC print offers a glossy, smooth finish with vibrant colors that enhance visual appeal, making it ideal for eye-catching displays. Rubber print provides a matte texture with a tactile, slightly raised surface, which improves grip and durability. Your choice depends on whether you prioritize vivid visuals or a textured, functional feel.

Color Vibrancy and Longevity

PVC Print offers superior color vibrancy due to its smooth surface, allowing for sharper and more vivid images compared to Rubber Print. Rubber Print, while durable, tends to have a matte finish that can dull colors over time, affecting visual impact. Your choice depends on whether you prioritize long-lasting brightness or enhanced durability in your print applications.

Eco-Friendliness and Safety Considerations

PVC print involves polyvinyl chloride, a plastic that can release harmful chemicals like dioxins during production and disposal, raising environmental and health concerns. Rubber print, often made from natural or synthetic rubber, tends to be more biodegradable and poses fewer risks related to toxic emissions. Both printing methods require careful management of materials and waste to ensure eco-friendliness and maintain safety standards in manufacturing and use.

Best Applications for PVC and Rubber Printing

PVC print excels in applications requiring vibrant, high-resolution graphics and durability, such as outdoor signage, promotional displays, and vehicle wraps due to its weather-resistant properties. Rubber print is ideal for flexible, tactile designs on apparel, labels, and sportswear, providing excellent stretchability and comfort without compromising print quality. Choosing between PVC and rubber printing depends on the need for rigidity and visual impact versus flexibility and wearability in the final product.

Choosing the Right Print Method for Your Needs

PVC print offers vibrant colors and high durability, making it ideal for durable outdoor signage and promotional materials. Rubber print provides a flexible, textured finish suitable for apparel and items requiring a soft touch and long-lasting wear resistance. Selecting between PVC and rubber print depends on the usability requirements, surface material, and desired visual or tactile effects to maximize print longevity and impact.

PVC Print vs Rubber Print Infographic

libmatt.com

libmatt.com