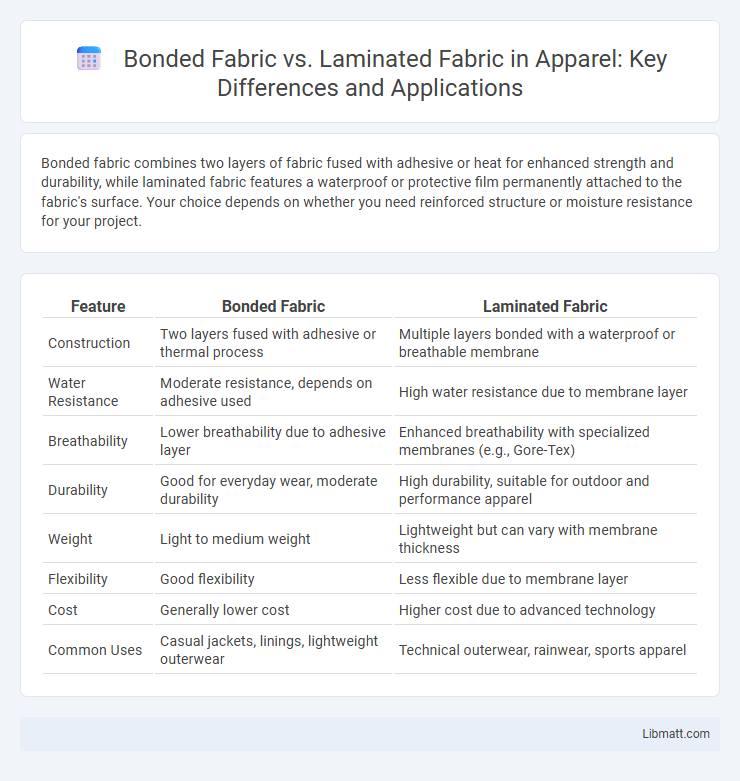

Bonded fabric combines two layers of fabric fused with adhesive or heat for enhanced strength and durability, while laminated fabric features a waterproof or protective film permanently attached to the fabric's surface. Your choice depends on whether you need reinforced structure or moisture resistance for your project.

Table of Comparison

| Feature | Bonded Fabric | Laminated Fabric |

|---|---|---|

| Construction | Two layers fused with adhesive or thermal process | Multiple layers bonded with a waterproof or breathable membrane |

| Water Resistance | Moderate resistance, depends on adhesive used | High water resistance due to membrane layer |

| Breathability | Lower breathability due to adhesive layer | Enhanced breathability with specialized membranes (e.g., Gore-Tex) |

| Durability | Good for everyday wear, moderate durability | High durability, suitable for outdoor and performance apparel |

| Weight | Light to medium weight | Lightweight but can vary with membrane thickness |

| Flexibility | Good flexibility | Less flexible due to membrane layer |

| Cost | Generally lower cost | Higher cost due to advanced technology |

| Common Uses | Casual jackets, linings, lightweight outerwear | Technical outerwear, rainwear, sports apparel |

Introduction to Bonded and Laminated Fabrics

Bonded fabrics consist of two or more layers of fabric joined together using adhesive or heat, creating a strong and durable material with enhanced insulation and structure. Laminated fabrics involve the application of a synthetic film or membrane to a textile, resulting in waterproof, breathable, and windproof properties ideal for outdoor apparel and technical gear. Both bonded and laminated textiles serve distinct functional purposes in fashion, upholstery, and industrial applications, offering improved performance and protection.

What is Bonded Fabric?

Bonded fabric is created by fusing two or more layers of fabric together using heat, adhesives, or pressure, enhancing strength and durability without adding significant weight. This technique improves insulation, water resistance, and structural integrity, making bonded fabric ideal for outdoor gear, upholstery, and technical clothing. Understanding bonded fabric can help you choose materials that offer superior performance and longevity for your projects.

What is Laminated Fabric?

Laminated fabric consists of two or more layers bonded together with a waterproof or protective membrane, enhancing durability and resistance to elements like water, wind, and abrasion. This fabric is widely used in outdoor gear, rainwear, and upholstery due to its superior waterproof and breathable properties. Unlike bonded fabric, laminated fabric typically includes a distinct film or coating that provides an additional functional barrier.

Manufacturing Processes Compared

Bonded fabric is produced by fusing two or more layers of fabric together using adhesives, heat, or ultrasonic welding, resulting in a flexible and durable material ideal for lightweight applications. Laminated fabric involves bonding a fabric layer with a polymer film or membrane through heat and pressure, providing enhanced waterproofing, windproofing, and structural stability. Your choice between bonded and laminated fabrics depends on the specific performance requirements in manufacturing processes, such as breathability or weather resistance.

Key Differences Between Bonded and Laminated Fabrics

Bonded fabrics consist of two or more layers of fabric fused together using adhesives or heat without adding extra thickness, offering enhanced softness and breathability. Laminated fabrics feature a waterproof or protective film layer bonded to the fabric surface, providing superior water resistance and durability ideal for outdoor gear and technical apparel. The key difference lies in the functional properties: bonded fabrics prioritize comfort and flexibility, while laminated fabrics deliver enhanced protection against elements.

Performance and Durability

Bonded fabric offers enhanced durability through the strong adhesion of two or more layers, providing resistance to tearing and abrasion, making it ideal for heavy-duty applications. Laminated fabric features a waterproof or breathable membrane fused to the base fabric, optimizing performance for weather resistance and moisture control in outdoor gear. Both fabrics enhance performance and durability, with bonded fabric excelling in structural strength and laminated fabric excelling in protective barrier properties.

Common Applications and Uses

Bonded fabric is commonly used in automotive upholstery, sportswear, and outdoor gear due to its enhanced durability and flexibility, making it ideal for products requiring strength and breathability. Laminated fabric finds frequent applications in rainwear, medical textiles, and protective clothing because of its waterproof and barrier properties. Your selection depends on whether you need moisture resistance or enhanced mechanical performance in the final product.

Advantages and Disadvantages

Bonded fabric offers advantages such as enhanced strength, improved durability, and resistance to water and wind, making it ideal for outerwear and technical garments; however, its stiffness can limit breathability and comfort. Laminated fabric provides superior waterproofing and windproofing while maintaining flexibility and comfort, but it may be more expensive and prone to delamination over time. Your choice depends on the specific performance requirements and durability expectations of the intended application.

Environmental Impact and Sustainability

Bonded fabric merges two layers using adhesives or heat, often involving synthetic materials that can hinder recyclability and increase environmental footprint. Laminated fabric applies a protective film or membrane, enhancing durability and water resistance, but may involve non-biodegradable components challenging to recycle. Choosing bonded or laminated fabric affects your sustainability goals by influencing waste generation and the fabric's end-of-life environmental impact.

Choosing the Right Fabric for Your Needs

Bonded fabric features two layers fused together through adhesives or heat, providing durability and a smooth finish ideal for upholstery and outerwear. Laminated fabric incorporates a waterproof or breathable film, making it perfect for rainwear, medical applications, and outdoor gear where moisture protection is essential. Understanding your specific requirements such as weather resistance, flexibility, or comfort will help you choose between bonded or laminated fabric for your project.

bonded fabric vs laminated fabric Infographic

libmatt.com

libmatt.com