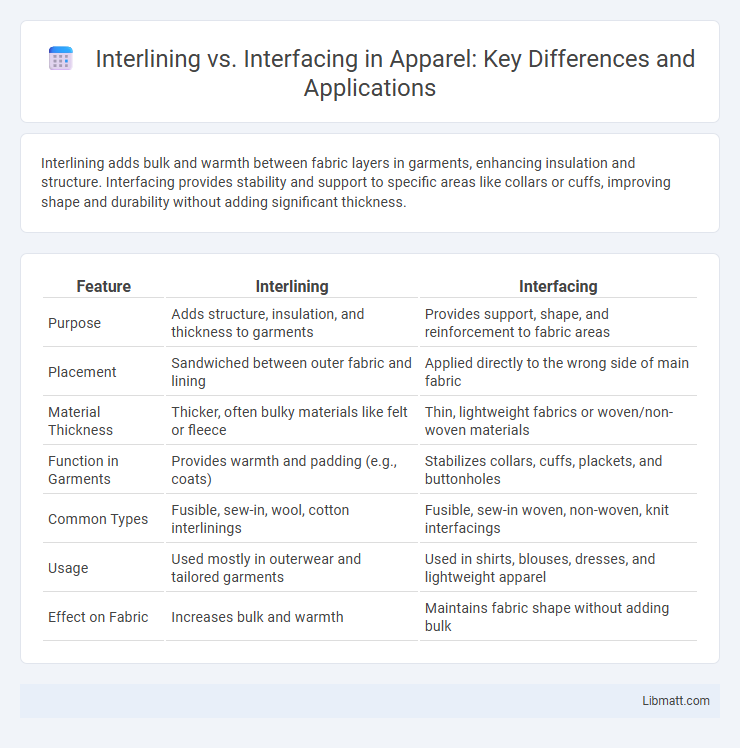

Interlining adds bulk and warmth between fabric layers in garments, enhancing insulation and structure. Interfacing provides stability and support to specific areas like collars or cuffs, improving shape and durability without adding significant thickness.

Table of Comparison

| Feature | Interlining | Interfacing |

|---|---|---|

| Purpose | Adds structure, insulation, and thickness to garments | Provides support, shape, and reinforcement to fabric areas |

| Placement | Sandwiched between outer fabric and lining | Applied directly to the wrong side of main fabric |

| Material Thickness | Thicker, often bulky materials like felt or fleece | Thin, lightweight fabrics or woven/non-woven materials |

| Function in Garments | Provides warmth and padding (e.g., coats) | Stabilizes collars, cuffs, plackets, and buttonholes |

| Common Types | Fusible, sew-in, wool, cotton interlinings | Fusible, sew-in woven, non-woven, knit interfacings |

| Usage | Used mostly in outerwear and tailored garments | Used in shirts, blouses, dresses, and lightweight apparel |

| Effect on Fabric | Increases bulk and warmth | Maintains fabric shape without adding bulk |

Understanding Interlining and Interfacing

Interlining and interfacing are essential fabrics used in garment construction to enhance structure and durability. Interfacing is typically a thin material fused or sewn on the inside of fabric layers to provide stiffness, shape, and support, commonly used in collars, cuffs, and waistbands. Interlining, a thicker layer inserted between fabric layers, adds warmth and insulation, often found in coats and heavy garments to improve comfort and thermal efficiency.

Key Differences Between Interlining and Interfacing

Interlining and interfacing are both fabric layers used in garment construction to add structure, but interlining is generally thicker and used for insulation and warmth, while interfacing is thinner, providing shape and stability to specific areas like collars and cuffs. Interlining is often placed between the garment's outer fabric and lining, whereas interfacing is usually fused or sewn directly onto the fabric's wrong side. The primary difference lies in their function: interlining enhances thermal properties, and interfacing reinforces fabric areas to maintain form and durability.

Types of Interlining Materials

Interlining materials vary widely, including woven, non-woven, and knitted types, each offering distinct levels of flexibility, stability, and thickness. Woven interlinings provide strength and durability for structured garments, while non-woven options offer easy application and lightweight support suitable for casual wear. Your choice of interlining directly impacts garment shape, comfort, and drape, making it essential to select the appropriate material based on fabric and design requirements.

Types of Interfacing Materials

Interfacing materials vary widely, including woven, non-woven, and knit options, each designed to provide different levels of stiffness and flexibility for garment construction. Woven interfacing offers durability and shape retention, making it ideal for collars and cuffs, while non-woven interfacing is lightweight and excellent for general use due to its fusible or sew-in properties. Knit interfacing stretches with fabric, making it suitable for knitwear to maintain elasticity without compromising structure.

Functional Purposes of Interlining

Interlining is primarily used to enhance the insulation, warmth, and moisture-wicking properties of garments, providing an additional layer between the outer fabric and the lining. It also improves the garment's structure and durability, supporting the fabric to maintain shape and resist wear. Unlike interfacing, which mainly reinforces specific areas like collars and cuffs, interlining serves a broader functional purpose across the entire garment.

Functional Purposes of Interfacing

Interfacing provides structural support, shape, and durability to fabric, making garments more stable and professional-looking. It reinforces areas prone to stress, such as collars, cuffs, waistbands, and buttonholes, enhancing longevity and wearability. By controlling fabric stretch and preventing distortion, interfacing ensures precision in garment construction and finish.

How to Choose Between Interlining and Interfacing

Choosing between interlining and interfacing depends on the desired garment structure and fabric type. Interlining adds bulk and warmth by layering between fabrics, ideal for coats and jackets, while interfacing provides stability and shape to collars, cuffs, and button plackets without extra thickness. Your decision should consider the fabric's weight, drape, and the finished garment's function to ensure the best support and appearance.

Common Applications in Garment Construction

Interlining is primarily used in outerwear such as coats and jackets to provide warmth, structure, and added weight, while interfacing is commonly applied in collars, cuffs, waistbands, and plackets to reinforce fabric areas and maintain shape. Interlining materials are often thicker and softer, designed to enhance insulation, whereas interfacing comes in various weights and fusible options to support specific garment parts without bulk. Both play crucial roles in garment construction by improving durability, fit, and overall finish in different targeted applications.

Tips for Sewing with Interlining and Interfacing

When sewing with interlining and interfacing, always pre-wash fabrics to prevent shrinkage and distortion. Use a pressing cloth and low to medium heat to avoid damaging adhesive properties or fabric fibers. Pin or baste layers carefully to ensure smooth alignment and avoid bubbling or shifting during sewing.

Final Thoughts: Making the Right Selection

Choosing between interlining and interfacing depends on the desired garment structure and fabric type, with interlining providing extra warmth and insulation, while interfacing offers shape and support. Consider the weight and drape of the fabric, project requirements, and end-use to ensure proper stabilization and durability. High-quality interlining materials like wool or flannel suit outerwear, whereas fusible or sew-in interfacing varieties work best for collars, cuffs, and button plackets.

Interlining vs interfacing Infographic

libmatt.com

libmatt.com