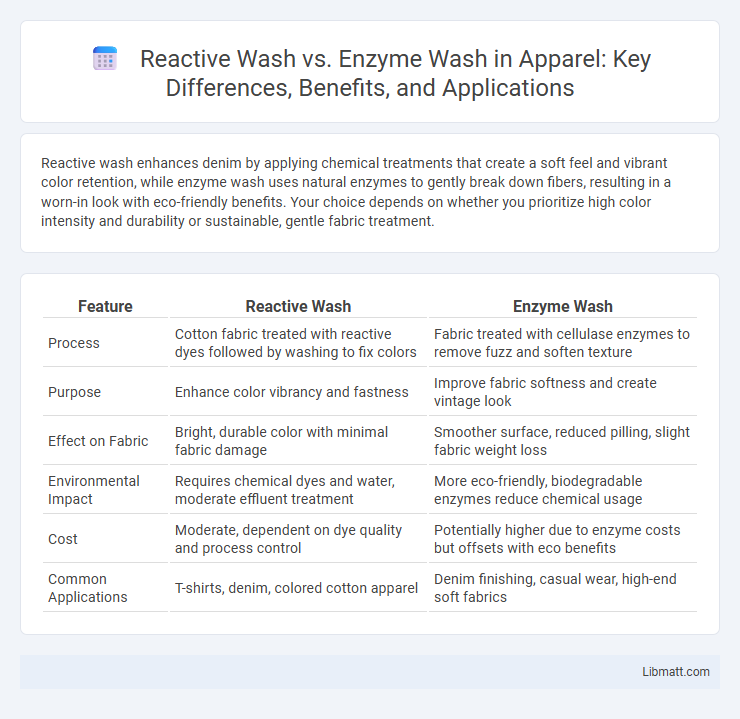

Reactive wash enhances denim by applying chemical treatments that create a soft feel and vibrant color retention, while enzyme wash uses natural enzymes to gently break down fibers, resulting in a worn-in look with eco-friendly benefits. Your choice depends on whether you prioritize high color intensity and durability or sustainable, gentle fabric treatment.

Table of Comparison

| Feature | Reactive Wash | Enzyme Wash |

|---|---|---|

| Process | Cotton fabric treated with reactive dyes followed by washing to fix colors | Fabric treated with cellulase enzymes to remove fuzz and soften texture |

| Purpose | Enhance color vibrancy and fastness | Improve fabric softness and create vintage look |

| Effect on Fabric | Bright, durable color with minimal fabric damage | Smoother surface, reduced pilling, slight fabric weight loss |

| Environmental Impact | Requires chemical dyes and water, moderate effluent treatment | More eco-friendly, biodegradable enzymes reduce chemical usage |

| Cost | Moderate, dependent on dye quality and process control | Potentially higher due to enzyme costs but offsets with eco benefits |

| Common Applications | T-shirts, denim, colored cotton apparel | Denim finishing, casual wear, high-end soft fabrics |

Introduction to Reactive Wash and Enzyme Wash

Reactive Wash utilizes advanced chemical processes to enhance fabric softness, color vibrancy, and durability by bonding reactive dyes to fibers during washing. Enzyme Wash employs natural enzymes like cellulase to gently remove excess fibers and surface fuzz, improving fabric texture and appearance without harsh chemicals. Both methods are popular in textile finishing for achieving distinct aesthetic and functional fabric qualities.

Understanding Fabric Finishing Processes

Reactive wash and enzyme wash are fabric finishing processes that enhance textile appearance and texture by targeting different chemical and biological mechanisms. Reactive wash uses chemical reactions to improve colorfastness and fabric softness, often involving dyes or reactive agents that bond with fibers. Enzyme wash employs biological enzymes to gently remove surface fibers and impurities, creating a smoother, softer fabric finish that enhances your garment's comfort and longevity.

What is Reactive Wash?

Reactive wash is a textile finishing process that involves chemically bonding reactive dyes to fibers, resulting in vibrant, long-lasting color with enhanced fabric durability. This method ensures superior color fastness compared to enzyme wash, which primarily uses enzymes to break down fibers for a softer feel and faded look. Reactive wash is particularly favored for achieving sharp, vivid hues on natural fibers like cotton and linen.

What is Enzyme Wash?

Enzyme wash is a textile finishing process that uses natural enzymes, typically cellulase, to break down the cellulose fibers in cotton fabrics, creating a softer texture and a worn-in look. This eco-friendly method reduces fabric pilling and enhances color fading without the harsh effects of traditional stone washing. Your garments treated with enzyme wash achieve a smoother feel and greater durability while maintaining an environmentally conscious approach.

Key Differences Between Reactive Wash and Enzyme Wash

Reactive wash uses chemical dyes that form strong covalent bonds with textile fibers, resulting in vibrant and long-lasting colors. Enzyme wash employs natural enzymes to gently remove surface fibers and soften fabric texture, improving garment feel and reducing pilling without altering color intensity significantly. Your choice between reactive wash and enzyme wash depends on whether you prioritize color durability or fabric softness and appearance.

Benefits of Reactive Wash

Reactive Wash enhances fabric durability and color vibrancy by chemically bonding dyes to fibers, resulting in longer-lasting garments. This technique reduces color fading and improves wash fastness compared to enzyme wash, ensuring your clothing retains its original look after multiple washes. Choosing Reactive Wash promotes a richer, more consistent color finish while maintaining fabric strength.

Advantages of Enzyme Wash

Enzyme wash offers significant advantages over reactive wash by providing a gentler, eco-friendly alternative that enhances fabric softness and reduces chemical waste. The use of bio-catalysts in enzyme wash lowers water and energy consumption while preserving the garment's durability and color vibrancy. This process also ensures consistent results and minimizes environmental impact, making it a preferred choice for sustainable textile production.

Applications in the Textile Industry

Reactive wash is widely used in the textile industry for achieving deep color fixation and enhanced fabric durability, primarily in denim production to create vibrant, long-lasting hues. Enzyme wash employs cellulase enzymes to selectively remove fuzz and soften the fabric, improving texture and reducing pilling in cotton-based textiles. Both techniques enhance fabric aesthetics and performance but target different effects, with reactive wash focusing on color stability and enzyme wash on fabric smoothness and wearability.

Environmental Impact: Reactive vs Enzyme Wash

Reactive wash processes typically involve synthetic chemicals that can generate hazardous wastewater and contribute to pollution, whereas enzyme wash utilizes natural enzymes that biodegrade organic matter, resulting in a significantly lower environmental footprint. Enzyme wash reduces water and energy consumption by working efficiently at lower temperatures and shorter durations, enhancing sustainability. Choosing enzyme wash for your textiles supports eco-friendly practices by minimizing chemical waste and conserving natural resources.

Choosing the Right Wash for Your Fabrics

Reactive wash enhances fabric durability and color retention by using chemical reactions to bond dyes, making it ideal for vibrant, long-lasting garments. Enzyme wash employs cellulase enzymes to gently remove surface fibers, resulting in softer texture and reduced pilling, perfect for delicate or worn-in denim. Selecting the right wash depends on fabric type and desired finish: choose reactive wash for colorfastness and strength, enzyme wash for softness and vintage appeal.

Reactive Wash vs Enzyme Wash Infographic

libmatt.com

libmatt.com