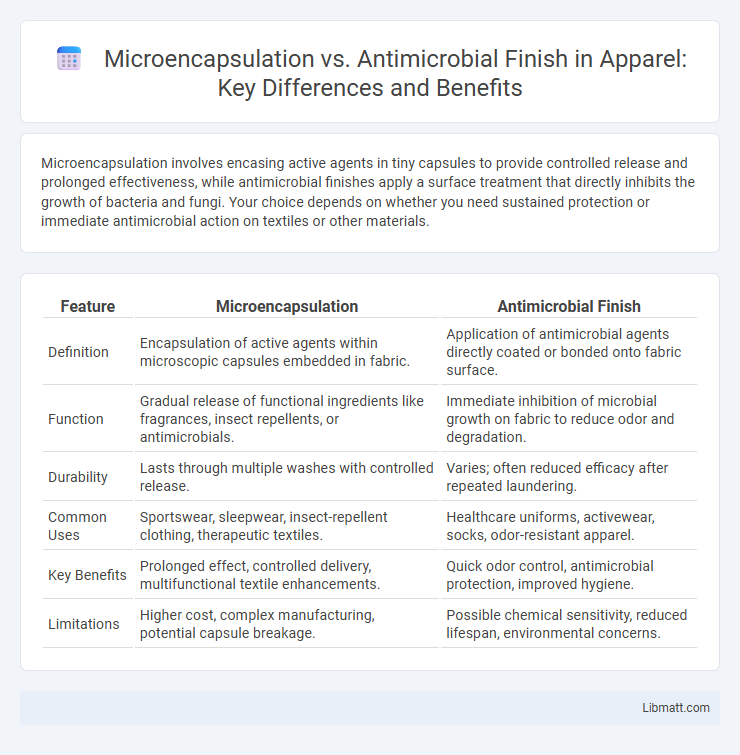

Microencapsulation involves encasing active agents in tiny capsules to provide controlled release and prolonged effectiveness, while antimicrobial finishes apply a surface treatment that directly inhibits the growth of bacteria and fungi. Your choice depends on whether you need sustained protection or immediate antimicrobial action on textiles or other materials.

Table of Comparison

| Feature | Microencapsulation | Antimicrobial Finish |

|---|---|---|

| Definition | Encapsulation of active agents within microscopic capsules embedded in fabric. | Application of antimicrobial agents directly coated or bonded onto fabric surface. |

| Function | Gradual release of functional ingredients like fragrances, insect repellents, or antimicrobials. | Immediate inhibition of microbial growth on fabric to reduce odor and degradation. |

| Durability | Lasts through multiple washes with controlled release. | Varies; often reduced efficacy after repeated laundering. |

| Common Uses | Sportswear, sleepwear, insect-repellent clothing, therapeutic textiles. | Healthcare uniforms, activewear, socks, odor-resistant apparel. |

| Key Benefits | Prolonged effect, controlled delivery, multifunctional textile enhancements. | Quick odor control, antimicrobial protection, improved hygiene. |

| Limitations | Higher cost, complex manufacturing, potential capsule breakage. | Possible chemical sensitivity, reduced lifespan, environmental concerns. |

Introduction to Microencapsulation and Antimicrobial Finishes

Microencapsulation involves enclosing active antimicrobial agents within microscopic capsules, allowing controlled release and prolonged effectiveness on treated surfaces. Antimicrobial finishes refer to surface treatments applied directly to textiles or materials to inhibit microbial growth and enhance hygiene. Your choice between microencapsulation and antimicrobial finishes depends on factors like durability, release mechanism, and specific application needs.

Understanding Microencapsulation Technology

Microencapsulation technology involves encapsulating active antimicrobial agents within a protective coating to enable controlled release and extended efficacy on textile surfaces. This method enhances durability and stability of antimicrobial properties compared to traditional antimicrobial finishes, which are often applied directly and may wash off more easily. Microcapsules improve targeted delivery and minimize environmental impact by reducing the quantity of biocides released.

Overview of Antimicrobial Finishing Techniques

Antimicrobial finishing techniques include microencapsulation and surface coatings that inhibit microbial growth on textiles. Microencapsulation involves encasing antimicrobial agents in microscopic capsules, providing controlled release and prolonged effectiveness. Antimicrobial finishes can also be applied through chemical bonding or physical coating, delivering immediate protection with varying durability based on the method and textile substrate.

Mechanism of Action: Microencapsulation vs Antimicrobial Finish

Microencapsulation works by enclosing antimicrobial agents within microscopic capsules that release their contents gradually through diffusion or triggered stimuli, ensuring prolonged and controlled antimicrobial activity. Antimicrobial finishes, on the other hand, function through direct surface interaction where active agents disrupt microbial cell membranes or inhibit metabolic processes upon contact. The controlled release mechanism of microencapsulation offers sustained protection, whereas antimicrobial finishes provide immediate but often shorter-lived antimicrobial efficacy.

Key Benefits of Microencapsulation in Textiles

Microencapsulation in textiles enhances the controlled release of active agents, ensuring prolonged antimicrobial efficacy and reducing the frequency of reapplication. This technology offers improved durability against washing and abrasion compared to traditional antimicrobial finishes, maintaining fabric performance over time. Furthermore, microcapsules provide targeted delivery and protection of sensitive compounds, optimizing fabric functionality and user safety.

Advantages of Antimicrobial Finishes in Fabrics

Antimicrobial finishes in fabrics provide long-lasting protection against bacteria, mold, and mildew, enhancing fabric hygiene and durability. These finishes reduce odor and degradation, maintaining fabric freshness and extending product lifespan without altering textile texture. Unlike microencapsulation, antimicrobial finishes offer continuous efficacy through repeated washes, ensuring persistent microbial resistance.

Performance Comparison: Durability and Efficacy

Microencapsulation technology offers superior durability by providing controlled, sustained release of antimicrobial agents, ensuring long-lasting protection compared to antimicrobial finishes that may degrade or wash away quickly. Antimicrobial finishes typically deliver immediate, but short-term efficacy, requiring frequent reapplication for consistent performance. Your choice depends on desired longevity and consistent antimicrobial activity, with microencapsulation providing enhanced durability and sustained efficacy.

Applications in Textile and Healthcare Industries

Microencapsulation in textiles offers controlled release of active agents such as fragrances, insect repellents, or drugs, enhancing fabric functionality and prolonged efficacy in healthcare garments and wound dressings. Antimicrobial finishes provide immediate surface protection by inhibiting bacterial growth on textiles, crucial for hospital uniforms, bedding, and medical devices to prevent infections. Both technologies improve hygiene and comfort but differ in duration and method of action, with microencapsulation enabling sustained delivery and antimicrobial finishes offering rapid antimicrobial activity.

Environmental and Safety Considerations

Microencapsulation offers enhanced environmental benefits by controlling the release of active agents, reducing chemical waste and minimizing exposure to harmful substances. Antimicrobial finishes often involve continuous leaching of biocides, which can pose risks to aquatic ecosystems and human health over time. You should consider microencapsulation as a safer, more sustainable choice for antimicrobial protection with lower environmental impact and improved user safety.

Future Trends: Innovations and Market Potential

Microencapsulation technology is evolving with advancements in nanomaterials and controlled release mechanisms, driving its application in antimicrobial finishes for textiles and medical devices. Innovations such as smart microcapsules that respond to environmental triggers enhance efficacy and durability, opening new market potential in healthcare, food packaging, and personal care sectors. The growing demand for sustainable and long-lasting antimicrobial solutions fuels investment and research, positioning microencapsulation as a key driver in the future antimicrobial finish market.

microencapsulation vs antimicrobial finish Infographic

libmatt.com

libmatt.com