RFID management offers real-time tracking and automated data capture, enhancing inventory accuracy and reducing human error compared to barcoded inventory systems that require manual scanning. Your business benefits from faster checkouts, improved stock visibility, and streamlined asset management with RFID technology.

Table of Comparison

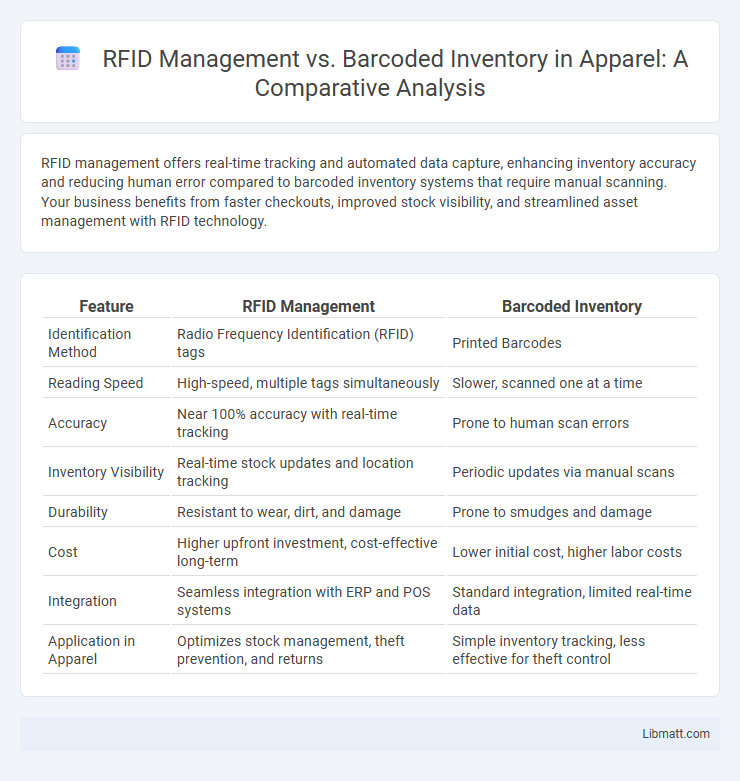

| Feature | RFID Management | Barcoded Inventory |

|---|---|---|

| Identification Method | Radio Frequency Identification (RFID) tags | Printed Barcodes |

| Reading Speed | High-speed, multiple tags simultaneously | Slower, scanned one at a time |

| Accuracy | Near 100% accuracy with real-time tracking | Prone to human scan errors |

| Inventory Visibility | Real-time stock updates and location tracking | Periodic updates via manual scans |

| Durability | Resistant to wear, dirt, and damage | Prone to smudges and damage |

| Cost | Higher upfront investment, cost-effective long-term | Lower initial cost, higher labor costs |

| Integration | Seamless integration with ERP and POS systems | Standard integration, limited real-time data |

| Application in Apparel | Optimizes stock management, theft prevention, and returns | Simple inventory tracking, less effective for theft control |

Introduction to RFID Management and Barcoded Inventory

RFID Management leverages radio frequency identification technology to enable real-time tracking and automated data collection of inventory, improving accuracy and efficiency. Barcoded Inventory relies on optical scanning of printed barcodes, requiring line-of-sight access and manual scanning to update stock information. The integration of RFID systems enhances inventory visibility and reduces human error compared to traditional barcoded inventory methods.

How RFID Technology Works

RFID technology uses radio waves to automatically identify and track tags attached to inventory, enabling real-time data capture without direct line of sight. Each RFID tag contains a microchip and antenna, which communicate with RFID readers to transmit unique product information. This system enhances inventory accuracy and speeds up the management process compared to traditional barcode scanning methods.

Understanding Barcoded Inventory Systems

Barcoded inventory systems rely on optical scanning technology to track products via unique printed codes, enabling quick identification and data capture at various checkpoints. These systems provide cost-effective and straightforward implementation, ideal for environments with moderate tracking needs and limited real-time visibility requirements. However, barcoded inventory requires line-of-sight scanning and manual handling, potentially slowing down processes compared to RFID solutions.

Key Differences Between RFID and Barcodes

RFID technology uses radio waves to automatically identify and track tags attached to objects, enabling faster, contactless data capture and bulk reading capabilities, unlike barcoded inventory which requires line-of-sight scanning for each individual item. RFID tags store more information and can update data in real-time, enhancing inventory accuracy and asset management, while barcodes are static and limited to encoding predefined numeric or alphanumeric data. Cost differences and infrastructure complexity vary significantly, with RFID involving higher initial investment but offering improved efficiency and scalability compared to traditional barcode systems.

Cost Comparison: RFID vs Barcoded Inventory

RFID management systems typically incur higher upfront costs compared to barcoded inventory due to the expense of RFID tags and readers, which can range from $0.10 to $0.50 per tag versus only a few cents for barcode labels. However, RFID significantly reduces labor costs by enabling faster scanning and real-time inventory tracking, improving accuracy by up to 95% compared to 70-80% with barcodes. Your decision should weigh initial investment against long-term efficiency gains and error reduction potential.

Accuracy and Data Collection Efficiency

RFID management significantly enhances accuracy by reducing human errors common in barcoded inventory systems, as RFID tags can be scanned automatically without direct line of sight. Data collection efficiency is improved since multiple RFID tags are read simultaneously in real-time, enabling faster inventory tracking and updates compared to the manual scanning required for barcodes. Optimizing Your inventory with RFID technology streamlines operations and ensures more reliable data integrity.

Scalability and Implementation Challenges

RFID management offers superior scalability compared to barcoded inventory due to its ability to read multiple tags simultaneously without line-of-sight, streamlining large-scale deployments in warehouses and retail environments. Implementation challenges for RFID include higher initial costs, the need for specialized readers and infrastructure, and potential interference issues, whereas barcoded systems are simpler and more cost-effective but face scalability limitations due to manual scanning requirements. Organizations must weigh RFID's efficient asset tracking and real-time data capabilities against the straightforward, low-cost setup of barcoded inventory when planning for expansion.

Security and Data Integrity Considerations

RFID management enhances security and data integrity through encrypted data transmission and unique tag identifiers, reducing risks of counterfeiting and unauthorized access compared to traditional barcoded inventory systems. Barcodes are prone to damage and duplication, which can lead to data inaccuracies and vulnerabilities in inventory tracking. Implementing RFID technology offers robust real-time monitoring capabilities that ensure precise data capture and minimize human error in inventory management.

Industry Applications and Use Cases

RFID management excels in industries requiring real-time tracking and high-speed inventory audits, such as retail, healthcare, and logistics, where automated scanning improves accuracy and reduces labor. Barcoded inventory remains popular in sectors like manufacturing and small-scale retail due to lower implementation costs and straightforward usage for batch processing. Your choice depends on factors like the need for rapid data capture, environmental conditions, and budget constraints.

Choosing the Right Solution for Your Inventory Needs

RFID management offers real-time tracking and faster data capture compared to barcoded inventory, which relies on manual scanning and line-of-sight limitations. Barcoded systems provide a cost-effective option for smaller inventories with less frequent updates, while RFID suits large-scale operations requiring enhanced accuracy and automation. Selecting the right solution depends on inventory size, budget constraints, and the need for speed and accuracy in asset tracking.

RFID Management vs Barcoded Inventory Infographic

libmatt.com

libmatt.com