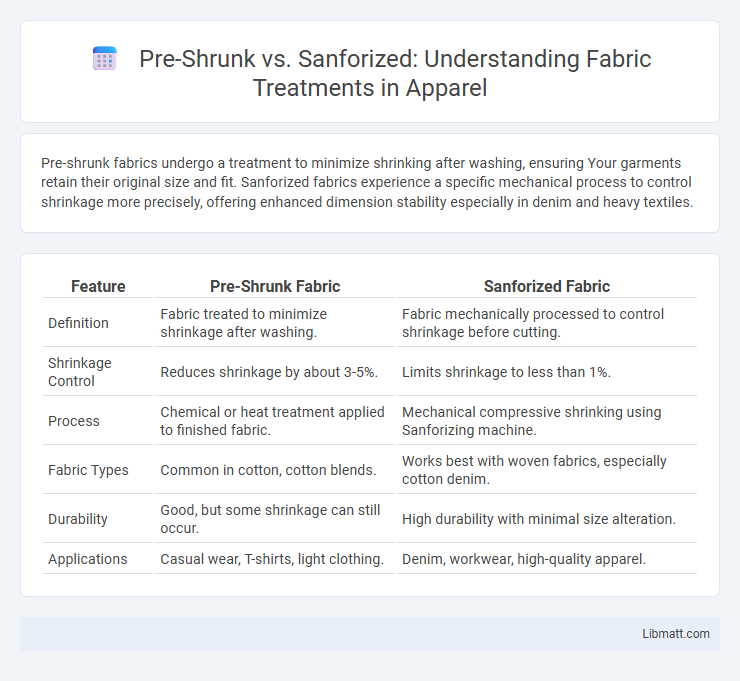

Pre-shrunk fabrics undergo a treatment to minimize shrinking after washing, ensuring Your garments retain their original size and fit. Sanforized fabrics experience a specific mechanical process to control shrinkage more precisely, offering enhanced dimension stability especially in denim and heavy textiles.

Table of Comparison

| Feature | Pre-Shrunk Fabric | Sanforized Fabric |

|---|---|---|

| Definition | Fabric treated to minimize shrinkage after washing. | Fabric mechanically processed to control shrinkage before cutting. |

| Shrinkage Control | Reduces shrinkage by about 3-5%. | Limits shrinkage to less than 1%. |

| Process | Chemical or heat treatment applied to finished fabric. | Mechanical compressive shrinking using Sanforizing machine. |

| Fabric Types | Common in cotton, cotton blends. | Works best with woven fabrics, especially cotton denim. |

| Durability | Good, but some shrinkage can still occur. | High durability with minimal size alteration. |

| Applications | Casual wear, T-shirts, light clothing. | Denim, workwear, high-quality apparel. |

Understanding Pre-Shrunk Fabrics

Pre-shrunk fabrics undergo a controlled shrinking process before garment construction to minimize size changes after washing, ensuring consistent fit and durability. Sanforized fabrics are treated with the Sanforization technique, compressing the material to reduce shrinkage by approximately 1% or less, offering enhanced dimensional stability. Both methods improve fabric reliability, with pre-shrunk emphasizing overall shrink control and Sanforized focusing on precise, minimal shrinkage.

What Does Sanforized Mean?

Sanforized refers to fabric treated through a controlled shrinking process to limit post-purchase shrinkage to less than 1%, ensuring garments maintain their original size and fit after washing. Pre-shrunk fabric undergoes mechanical or chemical treatments before garment construction but may still experience minor shrinkage, typically up to 3%. The Sanforization process involves precise stretching, shrinking, and fixing of the fabric to provide superior dimensional stability compared to standard pre-shrunk alternatives.

Pre-Shrunk vs Sanforized: Key Differences

Pre-shrunk fabrics have been treated to minimize shrinkage during washing, typically through heat-setting processes, whereas sanforized fabrics undergo a mechanical compression treatment that stabilizes the fabric's dimensions. Sanforization provides a more controlled and uniform shrinkage rate, often less than 1%, making it ideal for maintaining garment size consistency. Pre-shrunk fabrics may still experience minor shrinkage over time, while sanforized materials offer superior dimensional stability for durable apparel.

Shrinkage Resistance Explained

Pre-shrunk fabrics undergo controlled washing to minimize further shrinkage, ensuring dimensional stability during regular use. Sanforized textiles are mechanically compressed to prevent shrinkage, offering superior resistance by stabilizing fibers at the manufacturing stage. Both methods enhance shrinkage resistance, but sanforization typically provides more reliable long-term fabric stability.

Manufacturing Processes Compared

Pre-shrunk fabrics undergo controlled washing and drying to minimize shrinkage after garment production, ensuring consistent sizing during consumer use. Sanforized textiles utilize a mechanical process where the fabric is stretched, moistened, and compressed, permanently stabilizing dimensions to prevent post-purchase shrinkage. Both methods improve fabric reliability, but sanforization offers a more precise dimensional stability by altering the fabric structure during manufacturing.

Impact on Fabric Quality and Feel

Pre-shrunk fabrics undergo a controlled washing process before production, which reduces shrinkage and helps maintain consistent fabric size and shape, preserving garment quality and feel. Sanforized fabric is treated with a specialized mechanical stretching technique that enhances dimensional stability and softness, resulting in a smoother texture and longer-lasting comfort. Understanding these processes helps you choose clothing with reliable fabric performance and a comfortable, high-quality touch.

Durability and Longevity of Each Type

Pre-shrunk fabrics undergo a controlled drying process to minimize shrinking after purchase, which enhances your garment's durability by maintaining its original size and shape over time. Sanforized fabrics are treated through a mechanical process that compresses the fibers, offering superior dimensional stability and preventing excessive shrinkage during washing, resulting in longer-lasting clothing. Both methods improve longevity, but sanforized textiles typically provide greater resistance to distortion and wear, making them ideal for heavy-use items requiring consistent fit and durability.

Care Instructions: Pre-Shrunk vs Sanforized

Pre-shrunk fabrics have undergone a mechanical process before cutting to minimize shrinkage after washing, making care instructions straightforward with standard cold or warm water washing and low heat drying to maintain size. Sanforized fabrics go through a specialized treatment to control fabric expansion and contraction, allowing your garments to retain their measurements even with frequent washing but still benefit from gentle cycle washing and air drying to prolong fabric integrity. Understanding these differences ensures you follow the appropriate care routine, preserving your clothing's fit and longevity.

Common Uses and Applications

Pre-shrunk fabrics are widely used in casual apparel like t-shirts, jeans, and school uniforms to prevent significant shrinkage after washing, ensuring consistent fit and comfort. Sanforized textiles are primarily applied in high-quality dress shirts, upholstery, and home textiles where minimal dimensional change and fabric stability are crucial. Both treatments improve fabric performance, with Sanforizing offering more precise shrinkage control suited for premium and durable fabric applications.

Choosing the Right Fabric for Your Needs

Pre-shrunk fabrics have been washed and dried before sale to minimize further shrinkage, ensuring that your clothes maintain their original size and fit after washing. Sanforized fabrics undergo a controlled compressive shrinkage process, offering superior dimensional stability and preventing excessive shrinkage during manufacturing and consumer washing. Choosing between pre-shrunk and sanforized depends on your need for fabric stability and garment fit retention, with sanforized fabrics typically providing enhanced durability and consistent sizing.

pre-shrunk vs sanforized Infographic

libmatt.com

libmatt.com