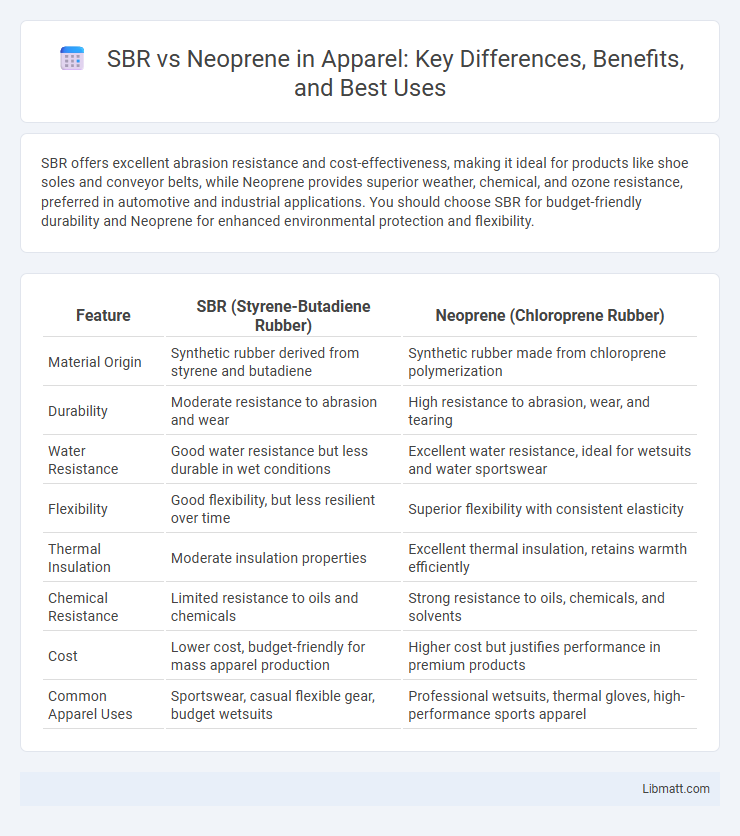

SBR offers excellent abrasion resistance and cost-effectiveness, making it ideal for products like shoe soles and conveyor belts, while Neoprene provides superior weather, chemical, and ozone resistance, preferred in automotive and industrial applications. You should choose SBR for budget-friendly durability and Neoprene for enhanced environmental protection and flexibility.

Table of Comparison

| Feature | SBR (Styrene-Butadiene Rubber) | Neoprene (Chloroprene Rubber) |

|---|---|---|

| Material Origin | Synthetic rubber derived from styrene and butadiene | Synthetic rubber made from chloroprene polymerization |

| Durability | Moderate resistance to abrasion and wear | High resistance to abrasion, wear, and tearing |

| Water Resistance | Good water resistance but less durable in wet conditions | Excellent water resistance, ideal for wetsuits and water sportswear |

| Flexibility | Good flexibility, but less resilient over time | Superior flexibility with consistent elasticity |

| Thermal Insulation | Moderate insulation properties | Excellent thermal insulation, retains warmth efficiently |

| Chemical Resistance | Limited resistance to oils and chemicals | Strong resistance to oils, chemicals, and solvents |

| Cost | Lower cost, budget-friendly for mass apparel production | Higher cost but justifies performance in premium products |

| Common Apparel Uses | Sportswear, casual flexible gear, budget wetsuits | Professional wetsuits, thermal gloves, high-performance sports apparel |

Introduction to SBR and Neoprene

SBR (Styrene-Butadiene Rubber) is a synthetic rubber known for its excellent abrasion resistance and cost-effectiveness, commonly used in tire manufacturing and industrial applications. Neoprene (Polychloroprene) offers superior chemical stability, weather resistance, and flexibility, making it ideal for outdoor gear, wetsuits, and automotive parts. Choosing between SBR and Neoprene depends on your need for durability versus environmental resistance.

Chemical Composition and Structure

SBR (Styrene-Butadiene Rubber) is a synthetic copolymer made from styrene and butadiene, characterized by a random copolymer structure that provides good abrasion resistance and heat aging properties. Neoprene (Polychloroprene) consists of chloroprene monomers, incorporating chlorine atoms into its polymer chain, which enhances its chemical stability, flame resistance, and oil resistance. Understanding these differences in chemical composition and molecular structure helps you choose the right material for applications requiring specific chemical and physical properties.

Key Physical Properties Compared

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and aging stability, making it ideal for automotive tires and conveyor belts, while Neoprene exhibits superior oil, chemical, and weather resistance, suitable for industrial seals and wetsuits. SBR typically has a tensile strength ranging from 15 to 25 MPa, with elongation at break between 300-500%, whereas Neoprene shows tensile strength from 12 to 20 MPa and elongation at break around 200-400%. Thermal stability also differs, with Neoprene maintaining performance from -40degC to 120degC, compared to SBR's narrower effective range of -50degC to 100degC.

Resistance to Chemicals and Oils

SBR (Styrene-Butadiene Rubber) offers moderate resistance to water-based chemicals but tends to degrade when exposed to oils and petroleum products, limiting its use in oily environments. Neoprene (Chloroprene Rubber) exhibits superior resistance to a wide range of chemicals, including oils, greases, and hydrocarbons, making it ideal for applications requiring durable protection. Choosing neoprene ensures your materials withstand harsh chemical exposures better than SBR, enhancing longevity and performance.

Durability and Longevity

SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance ideal for general-purpose applications, but it degrades faster when exposed to oils, heat, and ozone compared to Neoprene. Neoprene, known for superior chemical stability and resistance to weathering, maintains its durability and elasticity under harsh environmental conditions, making it a better choice for long-term use. Your selection between SBR and Neoprene should consider the specific exposure factors to ensure optimal longevity in your application.

Weather and Temperature Performance

SBR (Styrene-Butadiene Rubber) generally performs well in moderate weather but deteriorates faster under extreme temperatures and constant UV exposure compared to Neoprene. Neoprene offers superior weather resistance, maintaining flexibility and durability in a wider temperature range from -50degC to 120degC and resisting ozone, sunlight, and harsh chemicals effectively. Your choice should consider Neoprene if long-term exposure to varying temperatures and outdoor elements is critical for performance.

Cost and Availability

SBR (Styrene-Butadiene Rubber) generally costs less than Neoprene due to its widespread production and simpler manufacturing processes. SBR is readily available in large quantities, making it a popular choice for cost-sensitive applications. Neoprene, although more expensive and less abundant, offers superior chemical resistance and durability, which can justify the higher price in specialized uses.

Common Applications of SBR

Styrene-Butadiene Rubber (SBR) is widely used in automotive tires, conveyor belts, and footwear due to its excellent abrasion resistance and cost-effectiveness. Its durability and resistance to aging make it ideal for gaskets, hoses, and seals in industrial applications. SBR is also a common choice for flooring and roofing membranes, capitalizing on its flexibility and weather resistance.

Common Uses of Neoprene

Neoprene is commonly used in wetsuits, laptop sleeves, orthopedic braces, and automotive parts due to its excellent flexibility, durability, and resistance to water, oils, and chemicals. Its insulating properties make it ideal for cold weather applications and protective gear, providing comfort and thermal regulation. Your selection of neoprene products benefits from these qualities, ensuring long-lasting performance in diverse environments.

Which Rubber Material Should You Choose?

Choosing between SBR and Neoprene depends on your specific application requirements. SBR (Styrene-Butadiene Rubber) offers excellent abrasion resistance and cost-effectiveness, making it ideal for general-purpose use and outdoor environments. Neoprene provides superior chemical resistance, weather durability, and flexibility, which is essential for applications exposed to oils, chemicals, and extreme temperatures, helping you select the best rubber material for your needs.

SBR vs Neoprene Infographic

libmatt.com

libmatt.com