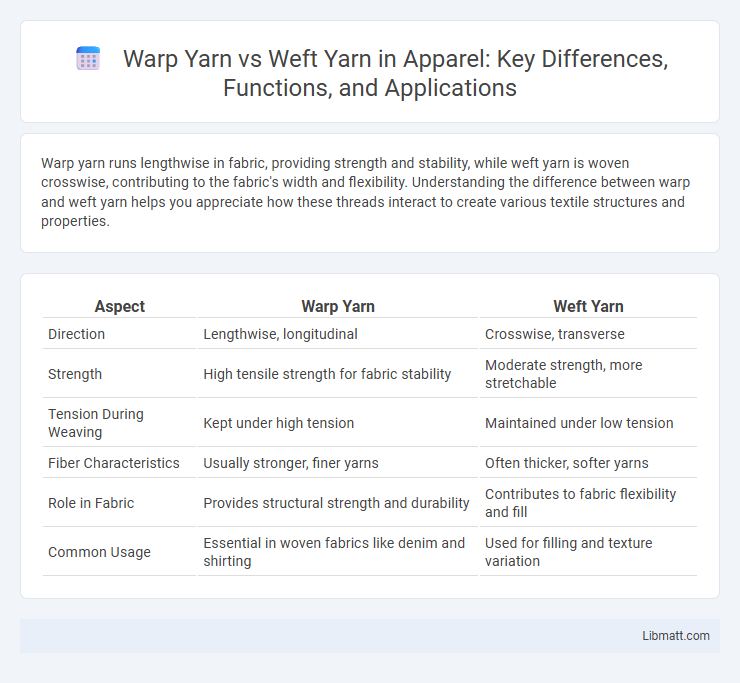

Warp yarn runs lengthwise in fabric, providing strength and stability, while weft yarn is woven crosswise, contributing to the fabric's width and flexibility. Understanding the difference between warp and weft yarn helps you appreciate how these threads interact to create various textile structures and properties.

Table of Comparison

| Aspect | Warp Yarn | Weft Yarn |

|---|---|---|

| Direction | Lengthwise, longitudinal | Crosswise, transverse |

| Strength | High tensile strength for fabric stability | Moderate strength, more stretchable |

| Tension During Weaving | Kept under high tension | Maintained under low tension |

| Fiber Characteristics | Usually stronger, finer yarns | Often thicker, softer yarns |

| Role in Fabric | Provides structural strength and durability | Contributes to fabric flexibility and fill |

| Common Usage | Essential in woven fabrics like denim and shirting | Used for filling and texture variation |

Introduction to Warp Yarn and Weft Yarn

Warp yarn consists of the longitudinal threads held stationary in a loom, providing the essential structural strength and foundation for woven fabric. Weft yarn runs horizontally, interlacing over and under warp yarns to create fabric patterns and texture variations. The interaction between warp and weft yarns determines the fabric's durability, flexibility, and appearance.

Definition of Warp Yarn

Warp yarn consists of the longitudinal threads held stationary on a loom during weaving, providing the fabric's structural foundation. These yarns run parallel to the selvage and are typically stronger and more tightly twisted than weft yarn. Understanding the characteristics of warp yarn helps you select appropriate materials for durable and high-quality textile production.

Definition of Weft Yarn

Weft yarn refers to the horizontal threads woven across the lengthwise warp yarns in a fabric, creating the crosswise structure essential for textile formation. It moves side to side through the warp during weaving, forming rows known as picks that determine the fabric's width and pattern. Understanding your fabric's weft yarn type helps optimize texture, durability, and design in textile manufacturing.

Key Differences Between Warp and Weft Yarn

Warp yarn runs lengthwise on the loom, providing structural strength and stability to the fabric, while weft yarn is interlaced crosswise, contributing to fabric flexibility and texture. Warp yarns are typically stronger and more tightly twisted to withstand tension during weaving, whereas weft yarns can be softer and more varied in thickness. Your choice between warp and weft yarn impacts the durability, appearance, and functionality of the final textile product.

Roles in Fabric Structure

Warp yarns run lengthwise and provide strength and stability to the fabric, forming the foundation of the weave. Weft yarns interlace horizontally across the warp, contributing flexibility and texture to the textile. Your fabric's durability and appearance significantly depend on the proper tension and interaction between warp and weft yarns.

Common Materials Used for Warp and Weft

Warp yarns are commonly made from strong, durable fibers such as cotton, polyester, and nylon to withstand tension during weaving, while weft yarns often use softer, more flexible materials like wool, silk, and acrylic for added texture and comfort. Your choice of yarn material affects fabric strength, elasticity, and overall feel, with warp yarns prioritizing tensile strength and weft yarns emphasizing aesthetic qualities. Natural fibers like cotton and wool are frequently combined with synthetic fibers to optimize performance and durability in woven textiles.

Strength and Durability Comparison

Warp yarns are typically stronger and more durable than weft yarns due to their role in withstanding the tension applied during weaving. Made from higher-tensile fibers and tightly twisted, warp yarns provide structural integrity and resistance to stretching and breaking. Understanding the strength differences between warp and weft yarns helps optimize fabric performance for your specific durability needs.

Applications in Textile Industry

Warp yarns, known for their strength and stability, are predominantly used in woven fabrics requiring durability, such as denim, canvas, and upholstery textiles. Weft yarns, which are more flexible and varied in texture, are typically employed in producing softer, more pliable fabrics like jersey knits, curtains, and lightweight apparel. The interaction between warp and weft yarns enables the creation of diverse textile structures tailored for applications ranging from industrial materials to high-fashion garments.

Advantages and Disadvantages of Each Yarn

Warp yarns offer high tensile strength and stability, making them ideal for the vertical foundation of woven fabrics, but they tend to be less stretchy and can break if overstressed. Weft yarns provide greater flexibility and elasticity, enhancing fabric comfort and drape, though they are typically weaker and less durable than warp yarns. Your choice between warp and weft yarns depends on the desired fabric characteristics, balancing strength with flexibility for optimal performance.

Conclusion: Choosing Between Warp and Weft Yarn

Choosing between warp and weft yarn depends on the fabric's intended strength and flexibility; warp yarns run lengthwise and provide tensile strength, while weft yarns run crosswise, offering more stretch and texture. Your decision should consider whether durability or elasticity is more critical for the textile application. Understanding the specific properties of each yarn type ensures optimal fabric performance and longevity.

Warp yarn vs weft yarn Infographic

libmatt.com

libmatt.com