Tear strength measures a material's resistance to the growth of cuts or tears, while tensile strength evaluates how much pulling force a material can withstand before breaking. Understanding the difference between these properties helps you select the right material for applications requiring durability and resistance to different types of stress.

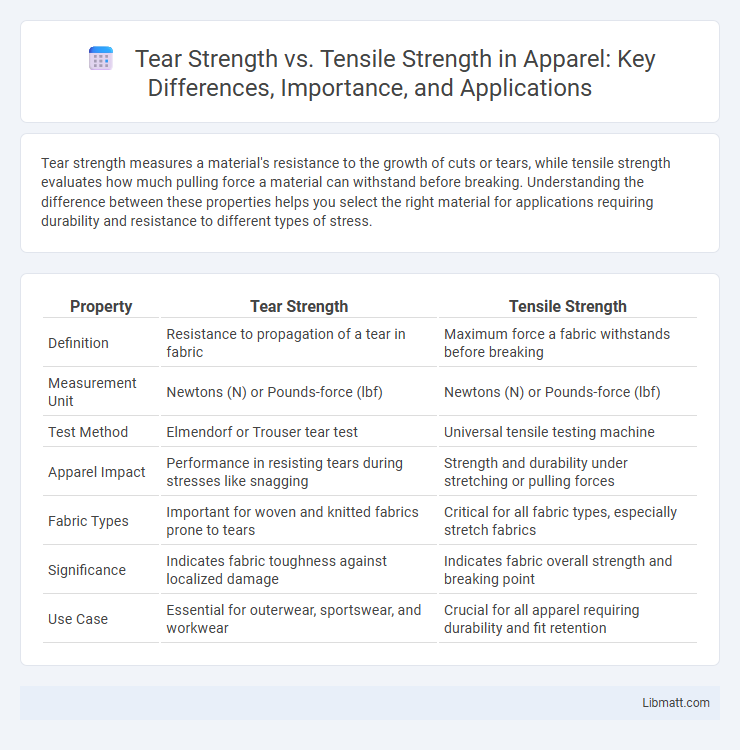

Table of Comparison

| Property | Tear Strength | Tensile Strength |

|---|---|---|

| Definition | Resistance to propagation of a tear in fabric | Maximum force a fabric withstands before breaking |

| Measurement Unit | Newtons (N) or Pounds-force (lbf) | Newtons (N) or Pounds-force (lbf) |

| Test Method | Elmendorf or Trouser tear test | Universal tensile testing machine |

| Apparel Impact | Performance in resisting tears during stresses like snagging | Strength and durability under stretching or pulling forces |

| Fabric Types | Important for woven and knitted fabrics prone to tears | Critical for all fabric types, especially stretch fabrics |

| Significance | Indicates fabric toughness against localized damage | Indicates fabric overall strength and breaking point |

| Use Case | Essential for outerwear, sportswear, and workwear | Crucial for all apparel requiring durability and fit retention |

Understanding Tear Strength and Tensile Strength

Tear strength measures a material's resistance to the propagation of a tear once it has started, while tensile strength evaluates the maximum stress a material can withstand when stretched before breaking. Understanding tear strength is crucial for applications where materials are prone to punctures or cuts, such as in rubber or fabric products. Tensile strength is vital for assessing durability under tension, commonly tested in metals, plastics, and composites to ensure structural integrity.

Key Differences Between Tear Strength and Tensile Strength

Tear strength measures a material's resistance to propagation of a cut or a tear, quantified in force per unit thickness, whereas tensile strength evaluates the maximum stress a material can endure while being stretched before breaking, expressed in units such as megapascals or psi. Tear strength is crucial for applications involving abrupt or sharp forces, common in rubber, textiles, and films, while tensile strength is essential for structural materials like metals and plastics under continuous load. Understanding these distinctions aids in selecting materials for durability under specific mechanical stresses, optimizing performance in engineering and manufacturing processes.

Importance of Tear Strength in Material Selection

Tear strength measures a material's resistance to tearing forces and is crucial in applications where durability under sudden, sharp stresses is required, such as in fabrics, rubber, and plastics. Its importance lies in preventing material failure during manufacturing and everyday use, ensuring longevity and safety. You should prioritize tear strength in material selection when durability against edge or puncture damage directly impacts product performance and reliability.

The Role of Tensile Strength in Engineering Applications

Tensile strength measures a material's ability to withstand pulling forces without breaking, making it critical for engineering applications that require load-bearing components such as bridges, aircraft, and automotive parts. This property ensures structural integrity and safety under tension, influencing design choices and material selection. High tensile strength materials prevent failure in mechanical stress situations, directly affecting durability and performance in engineering systems.

Factors Affecting Tear Strength

Tear strength depends on material composition, thickness, and molecular structure, which influence its resistance to propagation of cuts or tears. Unlike tensile strength, which measures the force needed to pull a material apart, tear strength is highly sensitive to flaws and edge conditions in your material. Proper understanding of factors such as temperature, strain rate, and environmental exposure helps optimize durability and performance in applications requiring resistance to tearing.

Factors Influencing Tensile Strength

Tensile strength is influenced by material composition, molecular alignment, and processing methods, which determine how much stress a material can withstand before breaking. Factors like temperature, strain rate, and the presence of defects or impurities also significantly affect tensile strength. Understanding these variables helps you select materials that meet specific mechanical performance requirements in applications.

Testing Methods for Tear Strength vs Tensile Strength

Tear strength is typically measured using tests like the Elmendorf tear test or trouser tear test, which evaluate the force required to propagate an existing cut in a material. Tensile strength testing involves uniaxial pulling of a specimen using a universal testing machine to determine the maximum stress a material can withstand before failure. Understanding these testing methods helps you choose the right metric for assessing material durability in applications such as textiles, plastics, or rubber products.

Common Materials and Their Tear vs Tensile Properties

Natural rubber exhibits high tear strength around 30-40 kN/m and tensile strength roughly 20-25 MPa, making it ideal for flexible, durable applications. Polyurethane shows superior tensile strength up to 50 MPa but lower tear resistance near 15-25 kN/m, suited for abrasion-resistant parts. Vinyl materials possess moderate tensile strength, about 20 MPa, with lower tear strength around 10-15 kN/m, often used in upholstery and flexible coverings.

Real-World Applications: Tear Strength vs Tensile Strength

Tear strength measures a material's resistance to propagation of an existing cut or flaw, making it crucial for applications like rubber gloves or automotive tires where sharp object punctures can occur. Tensile strength assesses the maximum stress a material can endure before breaking, important for structural components, ropes, or fabrics where stretching forces dominate. Understanding the difference helps you select the right material properties for durability, safety, and performance in products exposed to unique mechanical stresses.

Choosing the Right Material: Balancing Tear and Tensile Strength

Choosing the right material requires balancing tear strength and tensile strength to ensure durability and performance under stress. Tear strength measures a material's resistance to propagation of a cut or tear, while tensile strength reflects its ability to withstand pulling forces without breaking. Your selection should align with the specific application demands, prioritizing the property--tear or tensile strength--that best matches the expected physical challenges.

Tear Strength vs Tensile Strength Infographic

libmatt.com

libmatt.com