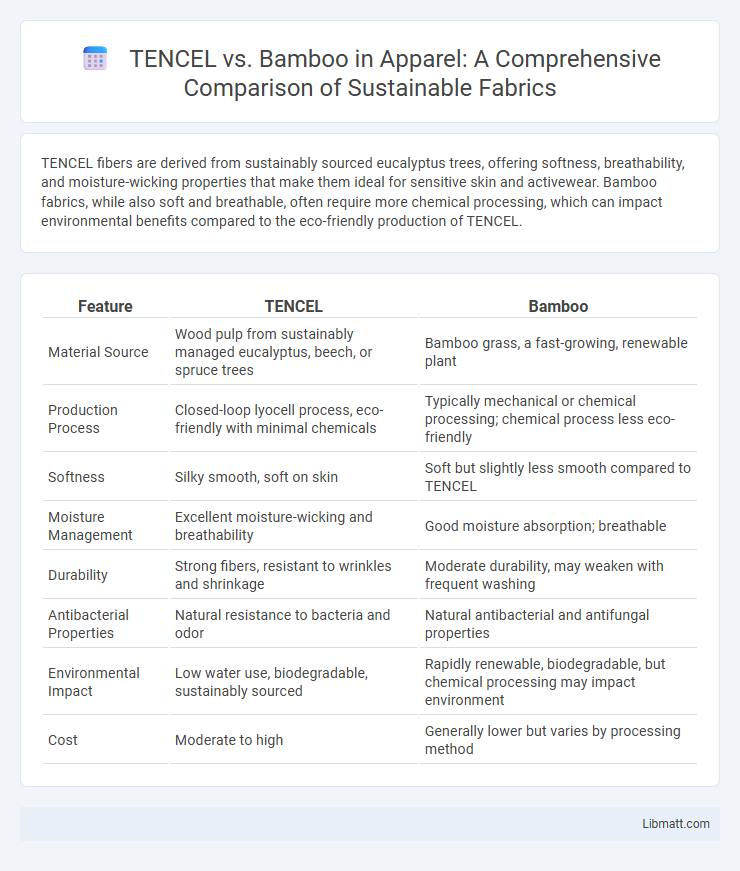

TENCEL fibers are derived from sustainably sourced eucalyptus trees, offering softness, breathability, and moisture-wicking properties that make them ideal for sensitive skin and activewear. Bamboo fabrics, while also soft and breathable, often require more chemical processing, which can impact environmental benefits compared to the eco-friendly production of TENCEL.

Table of Comparison

| Feature | TENCEL | Bamboo |

|---|---|---|

| Material Source | Wood pulp from sustainably managed eucalyptus, beech, or spruce trees | Bamboo grass, a fast-growing, renewable plant |

| Production Process | Closed-loop lyocell process, eco-friendly with minimal chemicals | Typically mechanical or chemical processing; chemical process less eco-friendly |

| Softness | Silky smooth, soft on skin | Soft but slightly less smooth compared to TENCEL |

| Moisture Management | Excellent moisture-wicking and breathability | Good moisture absorption; breathable |

| Durability | Strong fibers, resistant to wrinkles and shrinkage | Moderate durability, may weaken with frequent washing |

| Antibacterial Properties | Natural resistance to bacteria and odor | Natural antibacterial and antifungal properties |

| Environmental Impact | Low water use, biodegradable, sustainably sourced | Rapidly renewable, biodegradable, but chemical processing may impact environment |

| Cost | Moderate to high | Generally lower but varies by processing method |

Introduction to TENCEL and Bamboo Fabrics

TENCEL is a brand name for lyocell and modal fibers derived from sustainably harvested eucalyptus trees, known for their eco-friendly production process and soft, breathable texture. Bamboo fabric, made from bamboo pulp, offers natural antimicrobial properties and excellent moisture-wicking abilities but often involves chemical-intensive processing that can impact its sustainability. Choosing between TENCEL and bamboo depends on your preference for environmental impact, softness, and fabric performance.

Origin and Production Processes

TENCEL is produced from sustainably sourced eucalyptus wood through a closed-loop manufacturing process that recycles water and solvents, minimizing environmental impact. Bamboo fabric requires mechanical or chemical processing of bamboo fibers, with mechanical methods being more eco-friendly but less common due to higher costs. Your choice between TENCEL and bamboo should consider these distinct origins and production methods, which influence sustainability and fabric quality.

Environmental Impact Comparison

TENCEL fibers are produced through a closed-loop process that recycles water and solvents, significantly reducing environmental pollution compared to conventional fabric production. Bamboo fabric manufacturing often involves chemical-heavy processing, which can result in higher ecological footprints despite bamboo's rapid growth and natural sustainability. Choosing TENCEL supports a lower-impact textile option for Your eco-conscious wardrobe due to its renewable wood sources and efficient production methods.

Softness and Comfort

TENCEL fabric offers exceptional softness and moisture-wicking properties, making it breathable and comfortable for sensitive skin. Bamboo textiles are naturally hypoallergenic and provide a silky, smooth texture that enhances comfort and reduces irritation. Your choice between TENCEL and bamboo should prioritize softness and moisture management to ensure all-day comfort.

Breathability and Moisture Management

TENCEL fibers boast superior breathability due to their unique microfibril structure, allowing efficient air circulation and rapid moisture absorption, which keeps skin dry and comfortable. Bamboo fabric also offers good moisture management, naturally wicking away sweat and providing a cooling effect, though it tends to retain more moisture than TENCEL. Both materials excel in moisture regulation, but TENCEL outperforms bamboo in drying speed and breathability, making it ideal for activewear and sensitive skin.

Durability and Longevity

TENCEL fibers exhibit exceptional durability due to their strong cellulose structure derived from sustainable eucalyptus wood pulp, ensuring garments maintain shape and resist pilling after multiple washes. Bamboo fabric, while naturally antibacterial and soft, tends to break down more quickly because its fibers are shorter and less resilient, leading to faster wear and tear over time. Investing in TENCEL textiles results in longer-lasting clothing, making them a superior choice for durability and extended fabric life.

Skin Friendliness and Hypoallergenic Properties

TENCEL fibers are derived from sustainably sourced eucalyptus wood pulp and exhibit excellent skin friendliness due to their smooth surface, which reduces irritation and is ideal for sensitive skin. Bamboo fabric, known for its natural antibacterial and moisture-wicking properties, also supports hypoallergenic benefits but may require chemical processing that can affect purity. Both materials provide comfort and breathability, with TENCEL often preferred for its consistent hypoallergenic performance and eco-friendly production.

Cost and Market Availability

TENCEL fibers, derived from sustainably sourced eucalyptus trees, typically cost more than bamboo fabrics due to advanced lyocell processing and higher production standards, reflecting a premium eco-friendly market position. Bamboo textiles are generally more affordable and widely available, benefiting from large-scale cultivation and simpler manufacturing methods, though quality and sustainability vary significantly. Your choice between TENCEL and bamboo will depend on budget priorities and desired fabric performance within the current global textile market.

Maintenance and Care Requirements

TENCEL fabric requires gentle machine washing in cold water and low heat drying to maintain its softness and durability, with minimal risk of shrinking or pilling. Bamboo textiles benefit from similar care, needing cold or warm water washes and air drying or tumble drying on low, but are more prone to shrinkage if exposed to high temperatures. Both materials resist wrinkles and odors, making maintenance straightforward, though TENCEL's lyocell fibers typically offer greater longevity with consistent care.

Choosing Between TENCEL and Bamboo

Choosing between TENCEL and bamboo fabric depends on your priorities for sustainability, softness, and breathability. TENCEL is derived from sustainably managed eucalyptus forests, producing fiber through an eco-friendly closed-loop process, while bamboo fabric often involves chemical-intensive treatments unless labeled as mechanically processed. Your selection should consider TENCEL's superior moisture-wicking properties and hypoallergenic qualities compared to bamboo's natural antibacterial traits and varying environmental impacts.

TENCEL vs bamboo Infographic

libmatt.com

libmatt.com