Water-based ink offers eco-friendly, soft-to-the-touch prints with excellent breathability, making it ideal for lightweight fabrics and detailed designs. Plastisol ink provides vibrant, durable colors with superior opacity and is preferred for its ability to sit atop the fabric, ensuring long-lasting prints on various garment types.

Table of Comparison

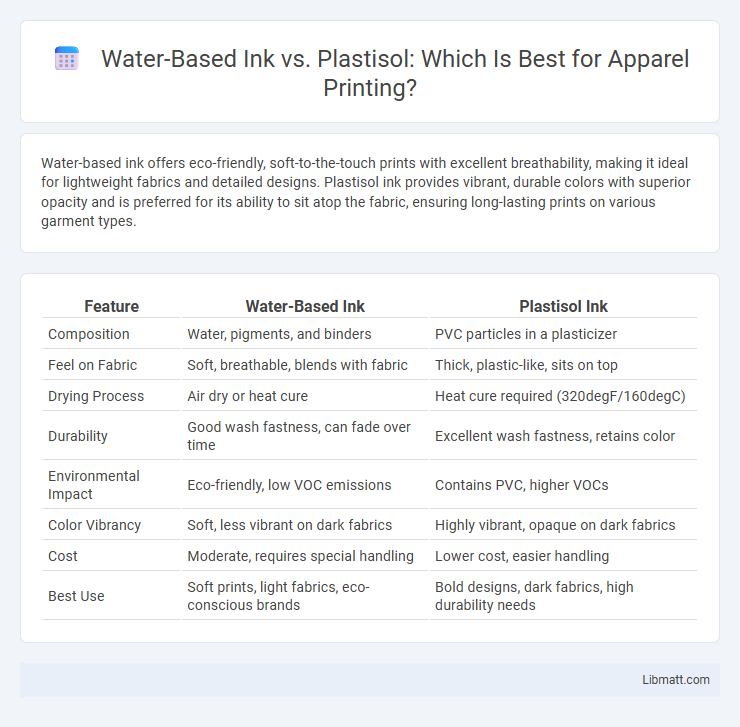

| Feature | Water-Based Ink | Plastisol Ink |

|---|---|---|

| Composition | Water, pigments, and binders | PVC particles in a plasticizer |

| Feel on Fabric | Soft, breathable, blends with fabric | Thick, plastic-like, sits on top |

| Drying Process | Air dry or heat cure | Heat cure required (320degF/160degC) |

| Durability | Good wash fastness, can fade over time | Excellent wash fastness, retains color |

| Environmental Impact | Eco-friendly, low VOC emissions | Contains PVC, higher VOCs |

| Color Vibrancy | Soft, less vibrant on dark fabrics | Highly vibrant, opaque on dark fabrics |

| Cost | Moderate, requires special handling | Lower cost, easier handling |

| Best Use | Soft prints, light fabrics, eco-conscious brands | Bold designs, dark fabrics, high durability needs |

Introduction to Screen Printing Inks

Water-based inks in screen printing offer eco-friendly, porous finishes that bond with fabric fibers, resulting in softer textures and vibrant colors; these inks are ideal for achieving breathable, durable prints. Plastisol inks, composed of PVC particles suspended in a plasticizer, provide opaque, glossy finishes with excellent adhesion and durability, especially on dark materials, making them preferred for high-detail or layered designs. Understanding the differences between these ink types is crucial for selecting the appropriate medium based on fabric type, desired print effect, and environmental considerations in screen printing projects.

Understanding Water-Based Ink

Water-based ink offers eco-friendly advantages due to its water-soluble properties, allowing for softer prints that integrate seamlessly with fabric fibers. Unlike plastisol, which sits on top of the fabric and requires curing, water-based ink soaks in, providing enhanced breathability and a vintage aesthetic. Your choice can impact the garment's feel, environmental footprint, and print durability.

What is Plastisol Ink?

Plastisol ink is a widely used ink in screen printing, known for its durability and vibrant colors. It consists of PVC particles suspended in a plasticizer, which allows it to sit on top of fabric rather than soaking in, creating a thick, opaque print. Unlike water-based ink, plastisol ink requires heat curing to properly set, making it ideal for bold, long-lasting designs on dark garments.

Environmental Impact: Water-Based vs Plastisol

Water-based ink significantly reduces environmental impact by using water as a solvent, minimizing volatile organic compounds (VOCs) and hazardous waste compared to plastisol ink, which contains PVC and phthalates. Plastisol inks require curing at high temperatures, contributing to greater energy consumption and pollution, whereas water-based inks cure at lower temperatures and biodegrade more easily. Choosing water-based ink supports your commitment to sustainability by promoting safer, eco-friendly printing processes.

Print Durability and Washability Comparison

Water-based ink offers superior breathability and a softer finish but tends to have lower print durability compared to plastisol, which forms a thicker, more resilient layer on fabric. Plastisol inks provide excellent washability, maintaining vibrant colors and sharp details through multiple laundering cycles, whereas water-based prints may fade or degrade faster with frequent washing. Choosing between the two depends on prioritizing environmental benefits and comfort with water-based inks or durability and wash retention offered by plastisol.

Feel and Appearance on Garments

Water-based ink soaks into fabric fibers, resulting in a softer, almost vintage feel that becomes more breathable and lightweight on garments. Plastisol ink sits on top of the fabric, creating a thicker, slightly raised print that offers vibrant colors but a heavier texture. Your choice depends on whether you prioritize a natural hand feel with subtle appearance or bold, durable prints with a pronounced tactile presence.

Application Techniques and Drying Processes

Water-based ink penetrates fabric fibers, allowing for soft hand feel and is best applied using screen printing with a slower curing process, requiring temperatures around 320degF for 1-2 minutes to evaporate moisture completely. Plastisol ink sits on top of the fabric, providing vibrant colors and durability, commonly applied through screen printing or heat transfer, and requires curing at approximately 330degF for 1-2 minutes to properly fuse the PVC particles. The drying process for water-based ink involves evaporation and absorption, whereas plastisol relies on heat curing to solidify the ink film.

Cost Analysis: Water-Based Ink vs Plastisol

Water-based ink generally offers lower upfront costs due to simpler cleanup and eco-friendly solvents, making it a cost-effective choice for small to medium print runs. Plastisol, while more expensive initially because of its chemical components and curing requirements, provides durability and vibrant colors that can reduce costs over large production volumes. Your choice hinges on balancing initial investment against long-term quality and volume needs for printing projects.

Common Uses and Industry Preferences

Water-based ink is commonly used in apparel printing for soft, breathable designs ideal for lightweight fabrics, favored by eco-conscious brands aiming for sustainable production. Plastisol ink dominates in the screen printing industry due to its durability, vibrant colors, and suitability for a wide range of textiles, especially heavier garments and complex prints. Industry preferences lean toward water-based inks for fashion and environmental benefits, while plastisol remains the top choice for bulk orders and high-opacity requirements.

Choosing the Right Ink for Your Screen Printing Needs

Water-based ink offers vibrant, soft prints that penetrate fabric fibers, making it ideal for lightweight, breathable apparel and eco-friendly projects. Plastisol ink provides durable, opaque colors with excellent adhesion on various textiles, perfect for bold designs and heavy-duty wear. Understanding your desired fabric feel, print longevity, and environmental impact helps you choose the right ink for your screen printing needs.

water-based ink vs plastisol Infographic

libmatt.com

libmatt.com