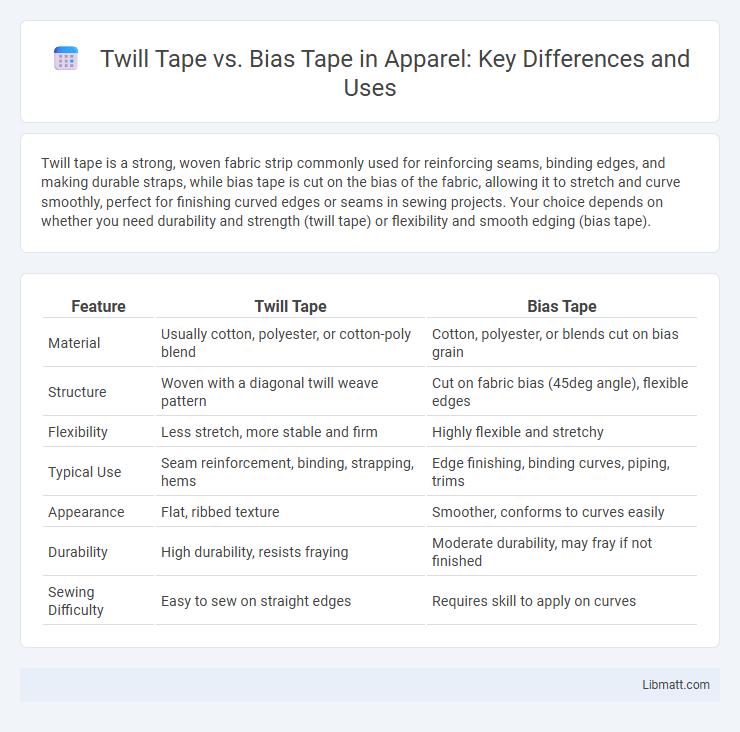

Twill tape is a strong, woven fabric strip commonly used for reinforcing seams, binding edges, and making durable straps, while bias tape is cut on the bias of the fabric, allowing it to stretch and curve smoothly, perfect for finishing curved edges or seams in sewing projects. Your choice depends on whether you need durability and strength (twill tape) or flexibility and smooth edging (bias tape).

Table of Comparison

| Feature | Twill Tape | Bias Tape |

|---|---|---|

| Material | Usually cotton, polyester, or cotton-poly blend | Cotton, polyester, or blends cut on bias grain |

| Structure | Woven with a diagonal twill weave pattern | Cut on fabric bias (45deg angle), flexible edges |

| Flexibility | Less stretch, more stable and firm | Highly flexible and stretchy |

| Typical Use | Seam reinforcement, binding, strapping, hems | Edge finishing, binding curves, piping, trims |

| Appearance | Flat, ribbed texture | Smoother, conforms to curves easily |

| Durability | High durability, resists fraying | Moderate durability, may fray if not finished |

| Sewing Difficulty | Easy to sew on straight edges | Requires skill to apply on curves |

Introduction to Twill Tape and Bias Tape

Twill tape is a sturdy, woven fabric strip commonly used for reinforcing seams, binding edges, and creating durable straps, often made from cotton, polyester, or a blend of fibers. Bias tape, cut on the fabric's bias, offers flexibility and stretch, making it ideal for finishing curved edges and providing a smooth, decorative trim in sewing projects. Understanding the differences between twill tape and bias tape can help you choose the right material to enhance the strength or aesthetic of your sewing work.

Key Differences Between Twill Tape and Bias Tape

Twill tape is a durable, woven cotton or polyester tape with a pronounced diagonal weave, commonly used for reinforcing seams and binding edges, while bias tape is cut on the fabric's bias grain, allowing stretch and flexibility for finishing curved edges smoothly. Twill tape maintains its shape and strength, making it ideal for structural uses, whereas bias tape conforms to curves, making it perfect for binding necklines, armholes, and hems. The fundamental difference lies in twill tape's straight grain construction versus bias tape's angled, stretchable cut, impacting their applications in sewing and crafting projects.

Materials and Construction of Twill Tape

Twill tape is typically woven from cotton, polyester, or a blend of both, featuring a distinct diagonal rib pattern that provides strength and durability. Unlike bias tape, twill tape is cut on the straight grain, which prevents stretching and maintains its shape under stress. Your choice of twill tape ensures robust reinforcement and a stable finish for sewing, upholstery, or binding projects.

Materials and Construction of Bias Tape

Bias tape is typically made from cotton, polyester, or a cotton-poly blend cut on the fabric's bias, which allows for greater flexibility and stretch around curves and edges. Its construction involves folding the fabric strips lengthwise and pressing them to create double or single-fold tape, ideal for binding seams and finishing raw edges in sewing projects. This process enhances the tape's durability and adaptability, distinguishing it from twill tape, which is woven and offers a sturdier, less flexible finish.

Common Uses for Twill Tape

Twill tape is commonly used for reinforcing seams, binding raw edges, and making sturdy ties in garments and upholstery. Its durable, woven cotton or polyester fibers provide strength in applications like canvas backpacks, outdoor gear, and heavy-duty sewing projects. Twill tape also serves as a reliable material for hemming, creating casings, and reinforcing buttonholes in both clothing and home decor items.

Common Uses for Bias Tape

Bias tape is commonly used in sewing projects to bind edges, create neat hems, and finish raw fabric edges with a clean, flexible finish. Its stretchy nature makes it ideal for curved seams and garment necklines, providing smooth contours without puckering. You can also use bias tape for decorative trims, quilting, and reinforcing seams in lightweight fabrics.

Strengths and Limitations of Twill Tape

Twill tape is known for its durability and strength, making it ideal for reinforcing seams, binding edges, and securing heavy fabrics in sewing and tailoring projects. Its woven construction provides excellent resistance to abrasion and stretching, but it lacks the flexibility and stretch of bias tape, limiting its use on curved or stretchy fabrics. You should choose twill tape when robust support and structural stability are key, though it may not be the best option for applications requiring smooth curves or decorative finishes.

Strengths and Limitations of Bias Tape

Bias tape offers excellent flexibility and conforms smoothly to curves, making it ideal for finishing garment edges and creating decorative trims. Its diagonal cut allows for stretch, but this same feature means it may not provide the same structural strength as twill tape in load-bearing or reinforcing applications. When choosing between the two, consider that bias tape enhances aesthetic appeal and edge durability, while twill tape excels in reinforcing and stabilizing seams for your sewing projects.

How to Choose: Twill Tape vs Bias Tape

Choosing between twill tape and bias tape depends on the project's structural needs and fabric stretch. Twill tape, made from tightly woven cotton or polyester, offers durability and minimal stretch, making it ideal for reinforcing seams, binding edges, or creating sturdy ties in heavy garments and upholstery. Bias tape, cut on the fabric's bias, provides flexibility and stretch, ideal for finishing curved edges, hems, and decorative trims on lighter or stretchy fabrics.

Conclusion: Which is Better for Your Sewing Project?

Twill tape offers durability and stability, making it ideal for reinforcing seams or creating strong bindings, while bias tape provides flexibility and stretch, perfect for finishing curved edges and adding a polished look. Your choice depends on the specific needs of your sewing project, such as the type of fabric and the desired finish. For structured garments or heavy-duty applications, twill tape is better; for delicate, curved, or lightweight fabric edges, bias tape delivers superior results.

twill tape vs bias tape Infographic

libmatt.com

libmatt.com