Yarn count determines the thickness and fineness of the yarn, directly affecting the fabric's density and texture, while fabric GSM (grams per square meter) measures the overall weight and quality of the fabric. Understanding the relationship between yarn count and fabric GSM helps you select materials suited for durability, comfort, and specific textile applications.

Table of Comparison

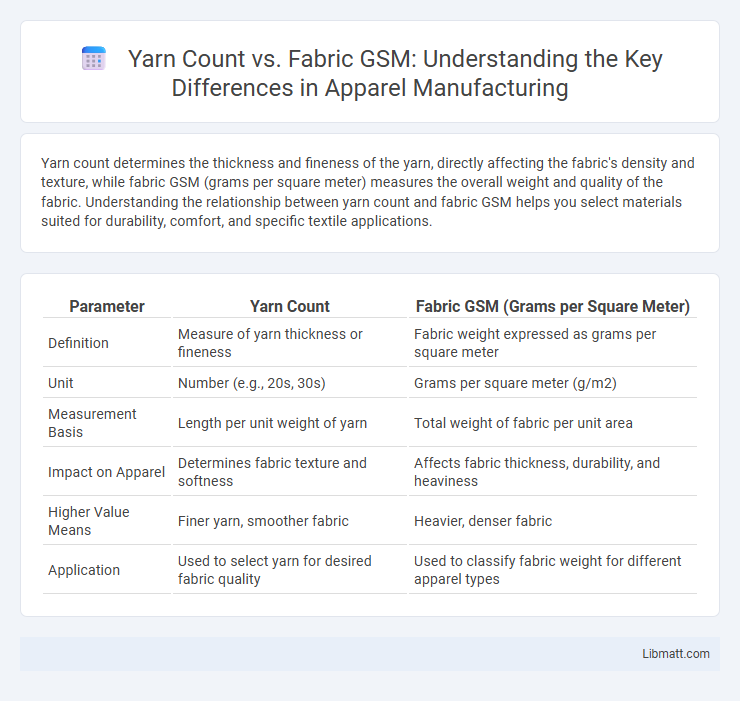

| Parameter | Yarn Count | Fabric GSM (Grams per Square Meter) |

|---|---|---|

| Definition | Measure of yarn thickness or fineness | Fabric weight expressed as grams per square meter |

| Unit | Number (e.g., 20s, 30s) | Grams per square meter (g/m2) |

| Measurement Basis | Length per unit weight of yarn | Total weight of fabric per unit area |

| Impact on Apparel | Determines fabric texture and softness | Affects fabric thickness, durability, and heaviness |

| Higher Value Means | Finer yarn, smoother fabric | Heavier, denser fabric |

| Application | Used to select yarn for desired fabric quality | Used to classify fabric weight for different apparel types |

Introduction to Yarn Count and Fabric GSM

Yarn count measures the fineness or thickness of yarn, typically expressed as the length of yarn per unit weight, influencing fabric texture and strength. Fabric GSM (grams per square meter) quantifies the fabric's weight, indicating its density and durability, essential for selecting appropriate material for specific textile applications. Understanding the relationship between yarn count and fabric GSM helps optimize fabric performance, balancing comfort, weight, and durability.

Understanding Yarn Count: Definition and Types

Yarn count refers to the numerical measure of yarn thickness, directly influencing fabric quality and feel. Common types include the English cotton count, which measures the number of 840-yard lengths per pound, and the metric count, expressed as kilometers per kilogram, determining fineness or coarseness. Understanding yarn count helps you select the ideal yarn for desired fabric GSM, ensuring optimal weight and texture in textile production.

Explaining Fabric GSM: Meaning and Calculation

Fabric GSM (grams per square meter) measures the weight of fabric, indicating its thickness and density, which directly impacts durability and comfort. Calculated by weighing a specific fabric area, typically one square meter, GSM provides a standardized metric to compare different fabrics regardless of yarn count. Accurate GSM assessment helps manufacturers optimize material selection and final product quality by correlating fabric weight with intended use and performance requirements.

Relationship Between Yarn Count and Fabric GSM

Yarn count directly influences fabric GSM (grams per square meter) by determining the thickness and density of the yarn used in weaving or knitting fabric. Higher yarn counts mean finer yarns, typically resulting in lighter fabrics with lower GSM, while lower yarn counts indicate thicker yarns that produce heavier fabrics with higher GSM. Understanding the relationship between yarn count and fabric GSM is essential for manufacturers to control fabric weight, texture, and performance characteristics.

Factors Affecting Yarn Count and Fabric GSM

Yarn count and fabric GSM are influenced by several key factors such as fiber type, yarn twist, and spinning method, which determine yarn thickness and strength. Fabric construction parameters, including weave pattern, thread density, and finishing processes, directly impact the GSM by controlling fabric weight per square meter. Variations in raw material quality and machinery settings also affect the balance between yarn count and fabric GSM, influencing overall textile performance and durability.

Impact of Yarn Count on Fabric Quality

Yarn count directly affects fabric GSM, where finer yarn counts typically produce lighter fabrics with higher thread density, enhancing softness and drape. Coarser yarn counts result in heavier fabric GSM, contributing to increased durability and thickness but potentially reducing fabric smoothness. Optimal yarn count selection balances fabric weight and tactile quality, influencing garment performance and comfort.

How Fabric GSM Influences Fabric Properties

Fabric GSM (grams per square meter) directly impacts fabric density, weight, and durability, with higher GSM indicating thicker, heavier textiles that provide better insulation and longevity. Yarn count, representing yarn thickness, complements GSM by affecting fabric softness and flexibility; finer yarns typically produce smoother, lighter fabrics with lower GSM. Understanding the interplay between yarn count and fabric GSM is crucial for optimizing textile properties such as breathability, strength, and drape in various applications.

Methods to Measure Yarn Count and Fabric GSM

Yarn count is measured using standardized methods such as the Tex system, which calculates yarn weight per 1,000 meters, and the Denier system, representing mass in grams per 9,000 meters, while indirect systems like the English Cotton Count gauge the length per unit weight. Fabric GSM (grams per square meter) is determined by weighing a precisely cut fabric sample of known dimensions and calculating the mass-to-area ratio, commonly using digital GSM cutters and electronic balances for accuracy. Both measurements are critical for textile quality control, influencing fabric strength, texture, and end-use performance.

Applications in Textile Industry: Choosing the Right Combination

Yarn count and fabric GSM directly influence the texture, durability, and weight of textile products, making their proper selection crucial for industry applications such as apparel, upholstery, and technical fabrics. Lower yarn counts combined with higher GSM create thicker, sturdier fabrics ideal for heavy-duty uses, while higher yarn counts with lower GSM yield lightweight, breathable textiles suited for summer clothing and delicate finishes. Understanding the balance between yarn count and GSM allows you to tailor fabric properties precisely to meet performance and comfort requirements.

Conclusion: Key Takeaways on Yarn Count vs Fabric GSM

Yarn count directly influences fabric GSM, with finer yarns typically producing lower GSM fabrics and coarser yarns resulting in higher GSM. Understanding the relationship between yarn count and fabric GSM is crucial for achieving desired fabric weight, texture, and durability in textile manufacturing. Accurate selection of yarn count ensures optimal fabric performance aligned with specific end-use requirements.

Yarn Count vs Fabric GSM Infographic

libmatt.com

libmatt.com