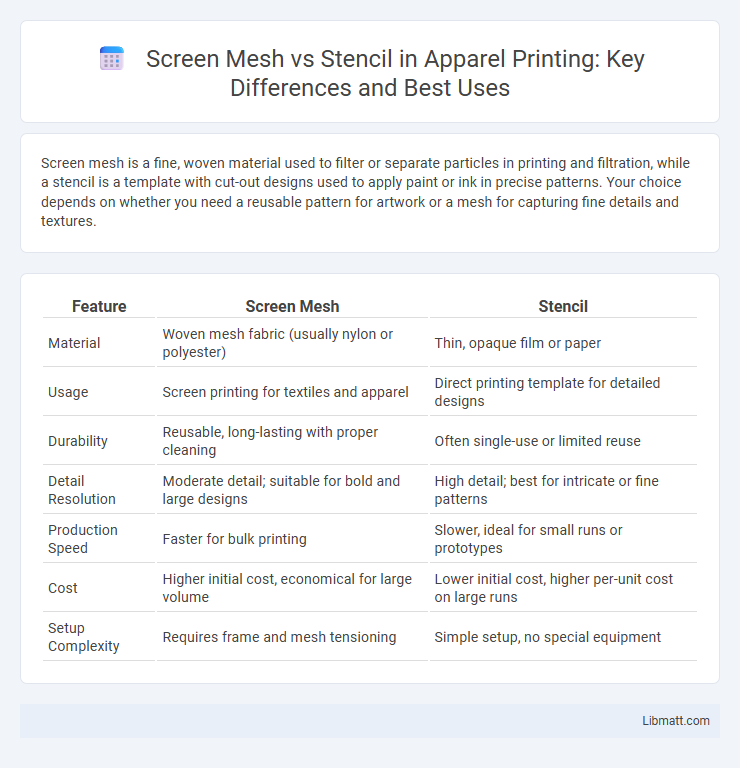

Screen mesh is a fine, woven material used to filter or separate particles in printing and filtration, while a stencil is a template with cut-out designs used to apply paint or ink in precise patterns. Your choice depends on whether you need a reusable pattern for artwork or a mesh for capturing fine details and textures.

Table of Comparison

| Feature | Screen Mesh | Stencil |

|---|---|---|

| Material | Woven mesh fabric (usually nylon or polyester) | Thin, opaque film or paper |

| Usage | Screen printing for textiles and apparel | Direct printing template for detailed designs |

| Durability | Reusable, long-lasting with proper cleaning | Often single-use or limited reuse |

| Detail Resolution | Moderate detail; suitable for bold and large designs | High detail; best for intricate or fine patterns |

| Production Speed | Faster for bulk printing | Slower, ideal for small runs or prototypes |

| Cost | Higher initial cost, economical for large volume | Lower initial cost, higher per-unit cost on large runs |

| Setup Complexity | Requires frame and mesh tensioning | Simple setup, no special equipment |

Introduction to Screen Mesh and Stencil

Screen mesh consists of a woven fabric with evenly spaced openings that control the flow of ink during printing, making it ideal for detailed and precise applications. Stencils use a thin material with cut-out shapes to transfer a design by blocking ink in specific areas, offering versatility for various surfaces and projects. Both techniques are fundamental in printmaking, with screen mesh excelling in fine detail and stencils providing quick, reusable patterns.

Key Differences Between Screen Mesh and Stencil

Screen mesh features a fine grid of woven wires allowing ink to pass through open areas while blocking others, ideal for precise, detailed patterns in screen printing. Stencils, composed of solid sheets with cut-out designs, function by physically masking portions of a surface to control where ink or paint is applied, suitable for simpler, less intricate images. The primary difference lies in mesh's ability to enable ink flow through its fabric versus stencils' reliance on direct openings, affecting detail resolution and application methods.

Materials Used in Screen Mesh vs Stencil

Screen mesh commonly uses materials like aluminum, stainless steel, and polyester, prized for their durability and resistance to corrosion in various industrial applications. Stencils, on the other hand, are often crafted from plastic, mylar, or metal sheets, chosen for their flexibility and ease of cutting intricate designs. Understanding these material differences can help you select the best option for your printing or filtering needs.

Printing Processes: Screen Mesh vs Stencil

Screen mesh enables precise ink transfer through woven threads, making it ideal for detailed, multi-color printing with consistent thickness in screen printing processes. Stencils offer a cost-effective approach for simpler designs by blocking ink application on specific areas, commonly used for single-color prints or quick prototyping. Screen mesh supports high-volume production with durability, while stencils favor flexibility and ease of customization in various printing workflows.

Cost Comparison: Screen Mesh vs Stencil

Screen mesh generally offers a lower upfront cost compared to stencils, making it a cost-effective choice for large-scale or repetitive printing tasks. Stencils, while more expensive initially due to custom design and production, provide higher precision and durability for detailed or limited-run projects. Evaluating your production volume and detail requirements helps determine whether screen mesh or stencil delivers better value for your specific printing needs.

Application Suitability: Screen Mesh vs Stencil Printing

Screen mesh offers superior versatility for printing on textiles, ceramics, and electronics due to its ability to handle thicker inks and uneven surfaces. Stencil printing excels in repetitive, high-precision applications like PCB solder paste application and fine art reproductions, where uniformity and detail are critical. Choosing screen mesh is ideal for multi-surface printing, whereas stencil printing suits specialized, high-accuracy processes on flat substrates.

Image Quality and Precision Differences

Screen mesh offers higher image quality and precision by using fine, continuous meshes that allow for detailed and consistent ink application, resulting in sharp and vibrant prints. Stencil printing relies on cut-out patterns that can produce less detailed images due to limitations in stencil resolution and potential ink bleeding. The choice between screen mesh and stencil impacts the overall sharpness, color accuracy, and crispness of the final print output.

Durability and Longevity of Screen Mesh and Stencils

Screen mesh offers superior durability due to its woven structure, which resists tearing and withstands repeated use in high-pressure applications. Stencils, often made from thinner materials like plastic or paper, have limited longevity and can degrade quickly with frequent exposure to inks and solvents. Your selection should consider screen mesh for long-term projects requiring consistent performance and stencils for short-term or single-use tasks.

Maintenance and Cleaning Requirements

Screen mesh requires regular cleaning to prevent clogging from dust and debris, often using brushes or compressed air to maintain optimal performance. Stencils demand careful handling and thorough cleaning after each use to avoid ink buildup that can impair print quality. Your choice depends on how much time you're willing to invest in upkeep, as screen mesh generally needs more frequent but simpler maintenance compared to the precise and delicate cleaning stencils require.

Choosing the Right Method: Screen Mesh or Stencil

Choosing between screen mesh and stencil depends on your project's detail, volume, and surface type. Screen mesh excels in high-volume printing with fine, consistent patterns, ideal for textiles and posters. Your decision hinges on stencil's suitability for simpler, bold designs on uneven surfaces where quick, low-volume prints are needed.

screen mesh vs stencil Infographic

libmatt.com

libmatt.com