Yarn evenness affects fabric uniformity and strength by ensuring consistent thickness throughout the yarn, while yarn hairiness influences the surface texture and potential for pilling, impacting the fabric's appearance and feel. Understanding the balance between evenness and hairiness helps optimize your textile products for durability and aesthetics.

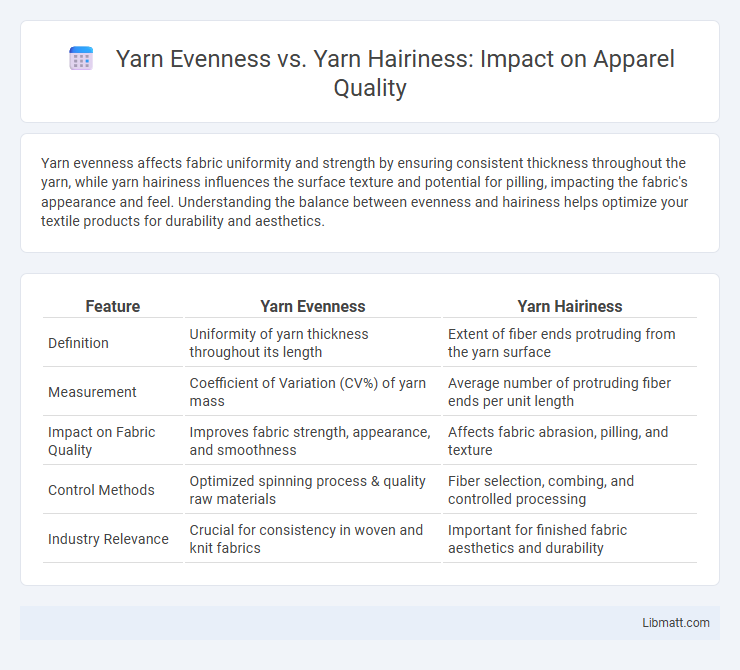

Table of Comparison

| Feature | Yarn Evenness | Yarn Hairiness |

|---|---|---|

| Definition | Uniformity of yarn thickness throughout its length | Extent of fiber ends protruding from the yarn surface |

| Measurement | Coefficient of Variation (CV%) of yarn mass | Average number of protruding fiber ends per unit length |

| Impact on Fabric Quality | Improves fabric strength, appearance, and smoothness | Affects fabric abrasion, pilling, and texture |

| Control Methods | Optimized spinning process & quality raw materials | Fiber selection, combing, and controlled processing |

| Industry Relevance | Crucial for consistency in woven and knit fabrics | Important for finished fabric aesthetics and durability |

Introduction to Yarn Evenness and Yarn Hairiness

Yarn evenness refers to the uniformity of the yarn's thickness along its length, crucial for producing high-quality textiles with consistent texture and strength. Yarn hairiness measures the extent of fiber ends protruding from the yarn surface, affecting fabric appearance, durability, and pilling tendency. Both parameters are essential in the textile industry for optimizing yarn performance and fabric aesthetics.

Defining Yarn Evenness

Yarn evenness refers to the uniformity of thickness or diameter along the length of the yarn, directly impacting the fabric's quality and appearance. High evenness reduces weak spots, enhances tensile strength, and ensures consistent dye absorption, resulting in smoother, more durable textiles. Unlike yarn hairiness, which pertains to fiber ends protruding from the yarn surface, yarn evenness focuses solely on the consistency of the yarn's cross-sectional profile.

Understanding Yarn Hairiness

Yarn hairiness refers to the protruding fibers extending from the yarn surface, impacting fabric appearance, strength, and pilling tendency. Measuring hairiness involves quantifying the number and length of fiber ends outside the yarn body, which directly affects the fabric's smoothness and tactile properties. Controlling yarn hairiness through spinning techniques enhances fabric quality by reducing fuzziness and improving dye absorption.

Factors Affecting Yarn Evenness

Yarn evenness depends heavily on fiber quality, spinning technology, and machine settings, which influence the uniformity of the yarn structure. Variations in fiber length, fiber fineness, and twist level directly impact your yarn's consistency, thereby affecting fabric appearance and strength. Precise control of these factors leads to minimized unevenness, improving fabric quality and performance.

Causes and Impact of Yarn Hairiness

Yarn hairiness is caused by fiber length irregularities and inadequate twisting during the spinning process, leading to protruding fibers on the yarn surface. Excessive hairiness increases fabric pilling, reduces fabric strength, and affects dyeing uniformity, thereby compromising the quality and durability of your textile products. Controlling spinning parameters and fiber selection is essential to minimize yarn hairiness and enhance fabric appearance and performance.

Measurement Techniques for Yarn Evenness

Yarn evenness is primarily measured using Advanced Uster Tester technology, which analyzes variations in yarn thickness by detecting irregularities over specific lengths. Techniques like capacitive or optical sensors provide precise assessments of yarn diameter consistency, essential for predicting fabric quality and performance. Your ability to control yarn evenness hinges on accurate data from these measurement tools, directly impacting the efficiency of the textile production process.

Methods for Evaluating Yarn Hairiness

Methods for evaluating yarn hairiness include using a hairiness tester, which measures the number and length of fiber ends protruding from the yarn surface, providing quantitative data crucial for quality control. Optical and image analysis techniques capture detailed images of yarn, enabling precise assessment of hairiness levels by analyzing fiber distribution. Accurate evaluation of yarn hairiness helps you optimize textile performance and fabric appearance by identifying and controlling unwanted fiber protrusions.

Effects on Fabric Quality and Performance

Yarn evenness directly influences fabric uniformity, strength, and appearance, with uneven yarn causing weak spots and visual defects that reduce fabric durability and aesthetic quality. Yarn hairiness affects fabric smoothness and pilling propensity, where higher hairiness leads to increased friction, fabric fuzziness, and potential wear issues over time. Optimizing yarn evenness and hairiness is crucial for achieving high-performance fabrics with consistent strength, improved comfort, and enhanced resistance to abrasion and pilling.

Solutions to Improve Yarn Evenness and Reduce Hairiness

Improving yarn evenness and reducing hairiness can be achieved by optimizing fiber selection, controlling the spinning process, and employing advanced machinery such as compact spinning systems that minimize fiber fly and imperfections. Implementing high-quality drafting systems and maintaining consistent tension during spinning also contribute to uniform yarn diameter and smoother surfaces. Regular monitoring and quality control using electronic evenness testers and hairiness meters enable timely adjustments that enhance overall yarn quality.

Future Trends in Yarn Quality Optimization

Future trends in yarn quality optimization emphasize advanced sensor technologies and AI-driven analytics to achieve superior yarn evenness and reduced hairiness. Innovations in spinning machinery enable real-time monitoring and adjustment, enhancing fiber alignment and minimizing imperfections for stronger, smoother yarns. Sustainable materials and eco-friendly processes are also driving improvements in yarn consistency, meeting increasing demands for high-performance textiles in the fashion and industrial sectors.

Yarn Evenness vs Yarn Hairiness Infographic

libmatt.com

libmatt.com