Thermal bonding uses heat and pressure to fuse materials, creating strong, durable joints ideal for textiles and packaging. Ultrasonic bonding employs high-frequency vibrations to generate localized heat, enabling fast, precise joins without adhesives or external heat, making it suitable for delicate or heat-sensitive materials.

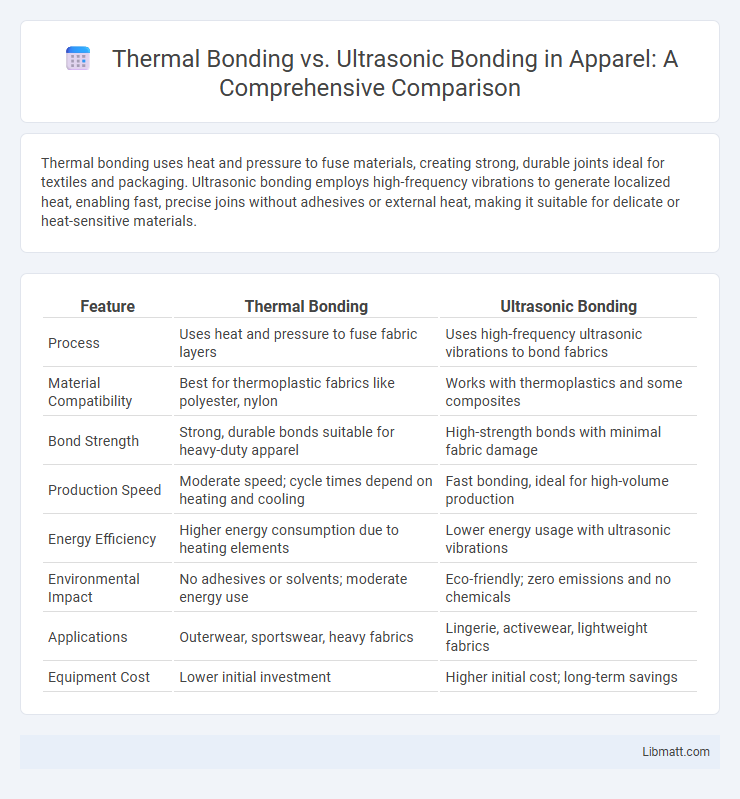

Table of Comparison

| Feature | Thermal Bonding | Ultrasonic Bonding |

|---|---|---|

| Process | Uses heat and pressure to fuse fabric layers | Uses high-frequency ultrasonic vibrations to bond fabrics |

| Material Compatibility | Best for thermoplastic fabrics like polyester, nylon | Works with thermoplastics and some composites |

| Bond Strength | Strong, durable bonds suitable for heavy-duty apparel | High-strength bonds with minimal fabric damage |

| Production Speed | Moderate speed; cycle times depend on heating and cooling | Fast bonding, ideal for high-volume production |

| Energy Efficiency | Higher energy consumption due to heating elements | Lower energy usage with ultrasonic vibrations |

| Environmental Impact | No adhesives or solvents; moderate energy use | Eco-friendly; zero emissions and no chemicals |

| Applications | Outerwear, sportswear, heavy fabrics | Lingerie, activewear, lightweight fabrics |

| Equipment Cost | Lower initial investment | Higher initial cost; long-term savings |

Introduction to Thermal and Ultrasonic Bonding

Thermal bonding uses heat and pressure to fuse materials, typically thermoplastics, creating strong and durable joints suitable for packaging and textiles. Ultrasonic bonding employs high-frequency ultrasonic vibrations to generate localized heat through friction, bonding materials quickly without external heat sources, ideal for delicate or heat-sensitive components. Understanding these techniques helps you select the most efficient bonding method for your specific application, balancing strength, speed, and material compatibility.

Fundamentals of Thermal Bonding

Thermal bonding relies on the application of heat and pressure to fuse materials, typically thermoplastics, by melting their surfaces and solidifying them together upon cooling. This process ensures strong, uniform bonds suitable for applications requiring durability and resistance to moisture or chemicals. Unlike ultrasonic bonding, thermal bonding does not involve high-frequency vibrations but depends on precise temperature control to achieve optimal adhesion.

Principles of Ultrasonic Bonding

Ultrasonic bonding utilizes high-frequency ultrasonic vibrations to create a solid-state weld by generating localized heat through friction between materials, typically thermoplastics or metals. This process enables precise, fast, and clean joints without requiring external adhesives or high temperatures. The principle relies on amplitude, frequency, and pressure control to achieve optimal bond strength and durability in applications such as electronics, automotive, and medical devices.

Key Differences Between Thermal and Ultrasonic Bonding

Thermal bonding relies on heat and pressure to fuse materials by melting their surfaces, while ultrasonic bonding uses high-frequency ultrasonic vibrations to create solid-state welds without external heat. Ultrasonic bonding offers faster processing times and is ideal for delicate components, whereas thermal bonding provides strong bonds suitable for thicker or more rigid materials. Your choice depends on factors such as material type, production speed, and bond strength requirements.

Advantages of Thermal Bonding

Thermal bonding offers advantages such as creating strong, durable seams by using heat to melt and fuse materials at the molecular level, ensuring high structural integrity without the need for adhesives or solvents. This method is ideal for bonding thermoplastics with consistent thickness and uniform material composition, resulting in improved product longevity and resistance to environmental factors like moisture and chemicals. Your manufacturing process can benefit from thermal bonding's clean, efficient operation, which is well-suited for mass production with minimal waste.

Benefits of Ultrasonic Bonding

Ultrasonic bonding offers precise, fast, and energy-efficient joining without the need for adhesives or heat, reducing material stress and deformation. This method enables strong, clean, and consistent bonds suitable for delicate or heat-sensitive materials, enhancing product durability and performance. Its eco-friendly nature and minimal waste generation make it ideal for high-volume manufacturing in electronics, textiles, and medical device industries.

Material Compatibility and Applications

Thermal bonding excels in joining thermoplastics such as polyethylene, polypropylene, and PVC, making it ideal for packaging, automotive interiors, and medical device assembly where heat resistance is crucial. Ultrasonic bonding is highly effective for delicate or thin materials like nonwovens, fabrics, and electronic components, commonly used in textile manufacturing, disposable hygiene products, and microelectronics. Material compatibility with thermal bonding demands heat-sensitive polymers that can withstand melting, while ultrasonic bonding accommodates a broader range of materials without significant thermal degradation.

Energy Efficiency and Process Speed

Thermal bonding typically requires higher energy input and longer cycle times due to the need for heating and cooling phases, making it less energy-efficient and slower compared to ultrasonic bonding. Ultrasonic bonding uses high-frequency vibrations to create bonds rapidly without excessive heat, significantly reducing energy consumption and increasing process speed. Optimizing your manufacturing with ultrasonic bonding can enhance throughput while minimizing operational costs linked to energy use.

Cost Comparison: Thermal vs Ultrasonic Bonding

Thermal bonding generally incurs higher energy costs and longer cycle times compared to ultrasonic bonding, making the latter more cost-efficient for high-volume production. Ultrasonic bonding requires less maintenance and consumes less power, reducing your overall operational expenses. Choosing ultrasonic bonding can lead to significant savings in both material waste and processing time, enhancing your manufacturing cost-effectiveness.

Choosing the Right Bonding Method for Your Application

Thermal bonding uses heat and pressure to fuse materials, ideal for applications requiring strong, durable seams in textiles and medical products. Ultrasonic bonding leverages high-frequency vibrations to create bonds without heat, making it optimal for heat-sensitive materials and fast production in electronics and packaging. Selecting the right bonding method depends on material compatibility, production speed, and the strength requirements of the final product.

thermal bonding vs ultrasonic bonding Infographic

libmatt.com

libmatt.com