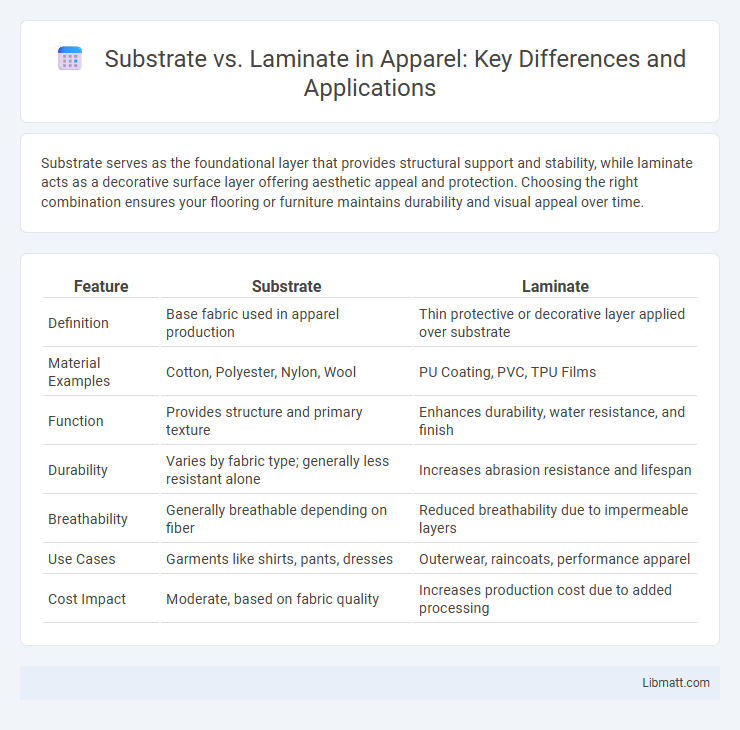

Substrate serves as the foundational layer that provides structural support and stability, while laminate acts as a decorative surface layer offering aesthetic appeal and protection. Choosing the right combination ensures your flooring or furniture maintains durability and visual appeal over time.

Table of Comparison

| Feature | Substrate | Laminate |

|---|---|---|

| Definition | Base fabric used in apparel production | Thin protective or decorative layer applied over substrate |

| Material Examples | Cotton, Polyester, Nylon, Wool | PU Coating, PVC, TPU Films |

| Function | Provides structure and primary texture | Enhances durability, water resistance, and finish |

| Durability | Varies by fabric type; generally less resistant alone | Increases abrasion resistance and lifespan |

| Breathability | Generally breathable depending on fiber | Reduced breathability due to impermeable layers |

| Use Cases | Garments like shirts, pants, dresses | Outerwear, raincoats, performance apparel |

| Cost Impact | Moderate, based on fabric quality | Increases production cost due to added processing |

Introduction to Substrate and Laminate

Substrate refers to the base material on which designs, coatings, or laminations are applied, typically consisting of materials like wood, metal, or fiberglass. Laminate is a composite material made by bonding multiple layers of substrate with a protective or decorative surface layer, enhancing durability and aesthetic appeal. The choice between substrate and laminate depends on the intended application, with substrates providing structural support and laminates offering surface protection and finish quality.

Definition and Core Differences

Substrate refers to the base material on which layers are applied, commonly used in electronics and printing industries as the foundational layer, while laminate is a composite material created by bonding multiple layers together for added strength and durability. The core difference lies in their roles: substrates serve as the foundational layer, whereas laminates are finished products designed to enhance surface properties. Substrates typically include materials like metal, plastic, or paper, whereas laminates combine substrates with films, adhesives, and protective coatings to achieve specific functional benefits.

Types of Substrates Used in Manufacturing

Common substrates used in manufacturing include paper, plastic films (such as PET and PVC), metals (like aluminum), and textiles, each offering unique properties for specific applications. Paper substrates provide affordability and printability, while plastic films offer durability and moisture resistance essential for flexible packaging. Metals, including aluminum foil, are chosen for their barrier properties and structural strength in food and pharmaceutical packaging.

Laminate Varieties and Their Applications

Laminate varieties include high-pressure laminates (HPL), low-pressure laminates (LPL), decorative laminates, and industrial laminates, each designed for specific applications like furniture, countertops, flooring, and wall panels. High-pressure laminates offer durability and resistance suited for heavy-use environments, while low-pressure laminates are typically used for light to medium commercial applications with a focus on cost-effectiveness. Understanding these laminate types helps you select the right material for aesthetic preferences, functional needs, and project durability requirements.

Material Composition and Structure

Substrate materials typically consist of a single, solid base layer such as wood, MDF, or stone, offering structural support and durability. Laminate consists of multiple layers including a wear layer, decorative film, and fiberboard core, combining aesthetic appeal with protection. The layered structure of laminate enhances resistance to scratches and moisture compared to the uniform composition of substrates.

Performance Characteristics Compared

Substrate materials provide foundational support and influence the overall durability and thermal stability of printed circuit boards, often exhibiting higher mechanical strength and heat resistance compared to laminates. Laminates are composite sheets combining resin and reinforcement fibers, offering superior electrical insulation and dimensional stability critical for high-frequency applications. Performance differences between substrates and laminates primarily impact signal integrity, thermal management, and mechanical reliability in electronic assemblies.

Cost Implications: Substrate vs Laminate

Substrate materials generally have a lower initial cost compared to laminate, making them a budget-friendly option for underlying layers in manufacturing and construction. Laminate, while more expensive, offers enhanced durability and aesthetic appeal, potentially reducing long-term maintenance expenses. Your choice between substrate and laminate should consider both upfront investment and lifecycle costs to ensure optimal value for your project.

Durability and Longevity

Substrate materials in flooring provide a foundational support layer that directly influences the durability and longevity of laminate floors by preventing warping and moisture damage. High-quality substrates like HDF (high-density fiberboard) enhance laminate stability and resistance to impacts compared to lower-grade particleboard substrates. Proper substrate selection extends the lifespan of laminate flooring by maintaining structural integrity under heavy foot traffic and environmental stress.

Industry-Specific Use Cases

Substrate materials are essential in industries like electronics and automotive manufacturing, providing a base for printed circuit boards (PCBs) and structural components due to their thermal resistance and mechanical stability. Laminate materials find extensive use in construction and furniture industries, offering durable, decorative surfaces that resist moisture and wear. Choosing between substrate and laminate depends on application-specific requirements such as electrical insulation, strength, surface finish, and environmental exposure.

Choosing the Right Material: Key Considerations

When choosing between substrate and laminate materials, consider durability, application purpose, and cost-efficiency to match your project needs. Substrates provide a foundational base often used for structural support, while laminates offer a protective, decorative surface enhancing aesthetics and resistance to wear. Your selection should balance functional requirements and budget constraints to ensure long-term performance and visual appeal.

Substrate vs laminate Infographic

libmatt.com

libmatt.com