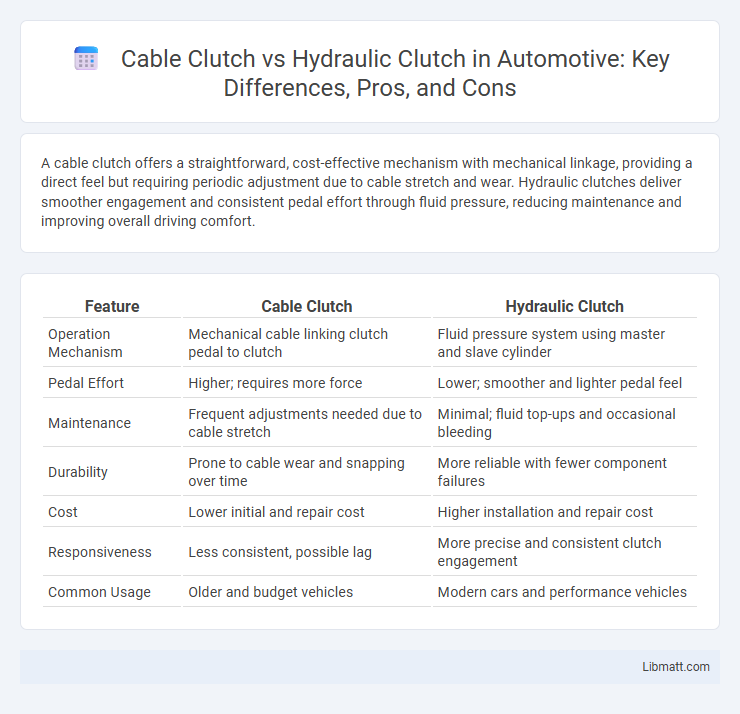

A cable clutch offers a straightforward, cost-effective mechanism with mechanical linkage, providing a direct feel but requiring periodic adjustment due to cable stretch and wear. Hydraulic clutches deliver smoother engagement and consistent pedal effort through fluid pressure, reducing maintenance and improving overall driving comfort.

Table of Comparison

| Feature | Cable Clutch | Hydraulic Clutch |

|---|---|---|

| Operation Mechanism | Mechanical cable linking clutch pedal to clutch | Fluid pressure system using master and slave cylinder |

| Pedal Effort | Higher; requires more force | Lower; smoother and lighter pedal feel |

| Maintenance | Frequent adjustments needed due to cable stretch | Minimal; fluid top-ups and occasional bleeding |

| Durability | Prone to cable wear and snapping over time | More reliable with fewer component failures |

| Cost | Lower initial and repair cost | Higher installation and repair cost |

| Responsiveness | Less consistent, possible lag | More precise and consistent clutch engagement |

| Common Usage | Older and budget vehicles | Modern cars and performance vehicles |

Introduction to Clutch Systems

Cable clutch systems use a mechanical wire to transfer force from the clutch pedal to the clutch mechanism, offering simplicity and lower maintenance costs. Hydraulic clutch systems employ fluid pressure to engage and disengage the clutch, providing smoother operation and reduced pedal effort. Your choice between cable and hydraulic clutches impacts overall vehicle performance and driving comfort.

Overview: Cable Clutch vs Hydraulic Clutch

A cable clutch uses a steel cable to mechanically transfer the driver's input from the pedal to the clutch mechanism, offering a straightforward, cost-effective design with easier maintenance. A hydraulic clutch employs fluid pressure in a master-slave cylinder system, providing smoother engagement, self-adjustment, and less pedal effort for improved driving comfort. While cable clutches are simpler and cheaper, hydraulic clutches deliver enhanced performance and reduced wear over time.

How Cable Clutch Mechanisms Work

Cable clutch mechanisms operate by transmitting the force from the clutch pedal to the clutch assembly through a steel cable, which pulls the clutch release fork to disengage the clutch. This system offers a direct mechanical connection, providing consistent pedal feel and simpler maintenance compared to hydraulic clutches. When you press the clutch pedal, the cable stretches slightly to engage the clutch, requiring periodic adjustments to maintain optimal performance.

How Hydraulic Clutch Systems Operate

Hydraulic clutch systems operate by using fluid pressure to transfer force from the clutch pedal to the clutch assembly, providing smoother and more consistent engagement compared to cable clutches. When the driver depresses the clutch pedal, hydraulic fluid is pushed through a master cylinder and moves to a slave cylinder, which then actuates the clutch fork to disengage the clutch. This hydraulic mechanism reduces pedal effort, offers self-adjustment for wear, and enhances overall driving comfort and precision.

Performance and Responsiveness Comparison

Cable clutches offer more direct mechanical feedback and precise control due to their simple, friction-based mechanism, making them ideal for performance driving where immediate response is crucial. Hydraulic clutches use fluid pressure to engage and disengage, providing smoother, more consistent pedal feel and reducing driver effort, which enhances responsiveness in stop-and-go traffic or daily driving scenarios. While cable clutches excel in tactile feedback and durability, hydraulic systems outperform in ease of operation and self-adjustment, impacting overall performance and responsiveness differently depending on driving conditions.

Maintenance Requirements and Costs

Cable clutches require regular adjustment and periodic cable replacement due to wear and stretching, resulting in lower maintenance costs but more frequent manual intervention. Hydraulic clutches involve fluid changes and potential leak repairs, generally offering smoother operation with less frequent maintenance but higher service expenses. Overall, cable clutches are more cost-effective short-term, while hydraulic systems provide longer-term durability with increased maintenance investment.

Durability and Longevity Factors

Cable clutches typically offer greater durability due to their simpler mechanical design and fewer components prone to wear, making them less susceptible to failure over time. Hydraulic clutches provide smoother operation but require regular maintenance of the fluid system to prevent leaks and degradation, which can affect longevity. Understanding these durability factors helps you choose a clutch system that aligns with your vehicle's usage and maintenance preferences.

Riding Comfort and User Experience

Cable clutches provide a more direct and tactile feel, making it easier for riders to gauge engagement and control, which enhances responsiveness during rides. Hydraulic clutches offer smoother operation with less lever effort, reducing rider fatigue and promoting comfort on longer journeys. Your choice impacts overall riding comfort, as hydraulic systems often deliver consistent performance under varying conditions compared to cable setups.

Suitability for Different Vehicle Types

Cable clutches are well-suited for smaller or older vehicles due to their simpler mechanical design and ease of maintenance, making them ideal for daily drivers and lightweight cars. Hydraulic clutches offer superior performance and smoother operation, making them preferable for high-performance vehicles, trucks, and modern cars requiring precise control and higher durability. Your choice should reflect the vehicle's power requirements and driving conditions to ensure optimal clutch responsiveness and longevity.

Choosing the Right Clutch: Key Considerations

Choosing the right clutch between cable and hydraulic systems depends on factors such as maintenance frequency, pedal feel, and cost efficiency. Cable clutches offer simpler mechanics and lower maintenance but can experience cable stretch and require periodic adjustments. Hydraulic clutches provide smoother engagement and self-adjustment, improving driving comfort, though they may involve higher initial costs and more complex repairs.

cable clutch vs hydraulic clutch Infographic

libmatt.com

libmatt.com