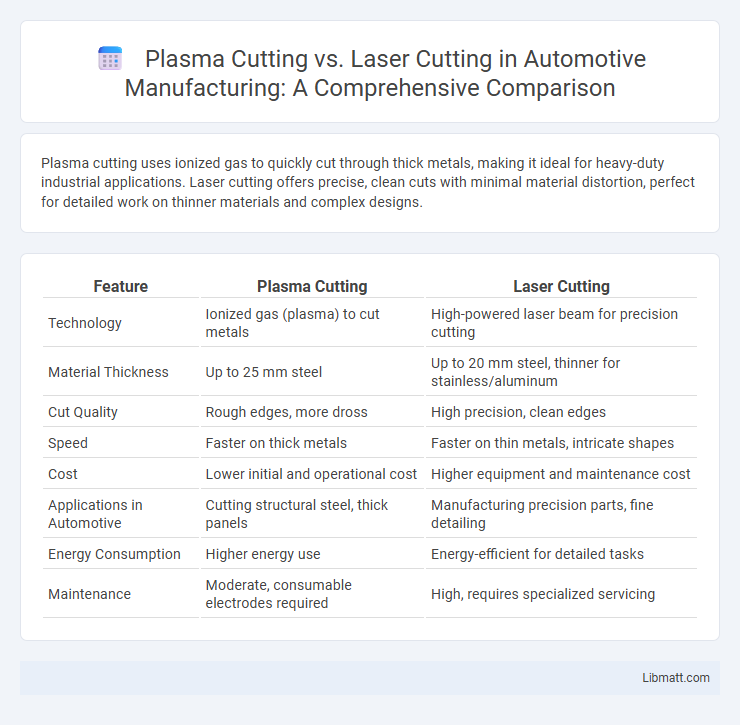

Plasma cutting uses ionized gas to quickly cut through thick metals, making it ideal for heavy-duty industrial applications. Laser cutting offers precise, clean cuts with minimal material distortion, perfect for detailed work on thinner materials and complex designs.

Table of Comparison

| Feature | Plasma Cutting | Laser Cutting |

|---|---|---|

| Technology | Ionized gas (plasma) to cut metals | High-powered laser beam for precision cutting |

| Material Thickness | Up to 25 mm steel | Up to 20 mm steel, thinner for stainless/aluminum |

| Cut Quality | Rough edges, more dross | High precision, clean edges |

| Speed | Faster on thick metals | Faster on thin metals, intricate shapes |

| Cost | Lower initial and operational cost | Higher equipment and maintenance cost |

| Applications in Automotive | Cutting structural steel, thick panels | Manufacturing precision parts, fine detailing |

| Energy Consumption | Higher energy use | Energy-efficient for detailed tasks |

| Maintenance | Moderate, consumable electrodes required | High, requires specialized servicing |

Introduction to Plasma Cutting and Laser Cutting

Plasma cutting utilizes an accelerated jet of hot plasma to cut through electrically conductive materials such as steel, aluminum, and copper with high precision and speed. Laser cutting employs a concentrated laser beam to melt, burn, or vaporize materials, offering superior accuracy for metals, plastics, and other thin substrates. Both cutting technologies are essential in manufacturing and fabrication, with plasma cutting excelling in thicker metals and laser cutting preferred for fine detail and minimal thermal distortion.

Key Differences Between Plasma and Laser Cutting

Plasma cutting uses electrically charged gas to cut conductive metals, offering rapid cutting speeds and cost-effectiveness for thicker materials up to 1 inch, while laser cutting employs focused light beams for high-precision cuts on thinner metals and non-metals up to 0.5 inches. Plasma cutting provides lower initial equipment costs and excels in rough cutting, whereas laser cutting delivers superior edge quality, tighter tolerances, and minimal heat-affected zones. The choice between plasma and laser cutting depends on material thickness, desired cut quality, and production volume requirements.

How Plasma Cutting Works

Plasma cutting operates by channeling an electrically conductive gas, such as compressed air or nitrogen, through a focused nozzle at high velocity, where an electric arc ionizes the gas into plasma. The plasma reaches temperatures exceeding 20,000degC, melting the metal while the high-speed gas blows away the molten material, making it ideal for thick, conductive metals. Your choice between plasma and laser cutting should consider plasma's efficiency in cutting thicker steel, aluminum, or stainless steel with speed and precision.

How Laser Cutting Works

Laser cutting uses a focused, high-powered laser beam to melt, burn, or vaporize materials, creating precise cuts with minimal material waste. The process involves directing the laser through optics and computer numerical control (CNC) to achieve intricate designs and smooth edges on metals, plastics, and other materials. Your choice of laser cutting optimizes accuracy and edge quality, especially for thin sheets and complex patterns.

Material Suitability for Each Method

Plasma cutting excels in cutting thick, conductive metals such as steel, stainless steel, and aluminum, making it ideal for heavy-duty industrial applications. Laser cutting offers superior precision on thinner materials, including metals, plastics, wood, and acrylics, providing clean edges and minimal heat-affected zones. Each method suits specific material types and thicknesses, with plasma favored for robust metals and laser preferred for fine, detailed cuts on diverse substrates.

Cutting Speed and Precision Comparison

Plasma cutting offers high cutting speeds ideal for thick metals but generally provides less precision, making it suitable for rough cuts and industrial fabrication. Laser cutting excels in precision with minimal kerf width and clean edges, delivering intricate detail work at high speeds on thinner materials like stainless steel and aluminum. Your choice depends on the balance between speed and precision required for the specific metal thickness and project complexity.

Cost Analysis: Plasma vs. Laser Cutting

Plasma cutting generally offers lower initial equipment costs and faster cutting speeds, making it cost-effective for thicker metals and industrial applications. Laser cutting, while more expensive upfront due to precision technology and maintenance, delivers superior accuracy and minimal material waste, increasing long-term efficiency in detailed or thin metal fabrication. Evaluating material thickness, production volume, and precision requirements is essential for determining the most cost-efficient cutting method for specific manufacturing needs.

Safety Considerations for Both Technologies

Plasma cutting and laser cutting each require strict safety measures due to high temperatures, intense light, and potential exposure to harmful fumes. Plasma cutting poses risks from flying sparks and molten metal, necessitating protective gear such as gloves, goggles, and flame-resistant clothing, while laser cutting demands barriers or enclosures to prevent eye damage from the concentrated beam. Ensuring proper ventilation and following manufacturer guidelines can protect Your health and workplace safety when operating either technology.

Maintenance and Operational Requirements

Plasma cutting requires regular maintenance of consumables such as electrodes and nozzles due to wear from high electrical discharge, while laser cutting systems demand precise alignment and cleanliness of optical components like lenses and mirrors to maintain cutting accuracy. Operationally, plasma cutters tend to have lower initial costs and are more effective on thicker, conductive metals, whereas laser cutters offer higher precision and speed, ideal for detailed work with thinner materials but often involve higher energy consumption. Choosing between the two depends on balancing maintenance intensity, operational efficiency, and material specifications.

Choosing the Right Cutting Method for Your Application

Plasma cutting excels at fast, cost-effective cutting of thick conductive metals like steel and aluminum, making it ideal for heavy fabrication and industrial projects. Laser cutting offers unparalleled precision and clean edges on thinner materials, perfect for intricate designs and applications requiring minimal post-processing. Understanding your material type, thickness, and desired finish helps you select the most efficient cutting method for your specific application.

Plasma cutting vs Laser cutting Infographic

libmatt.com

libmatt.com