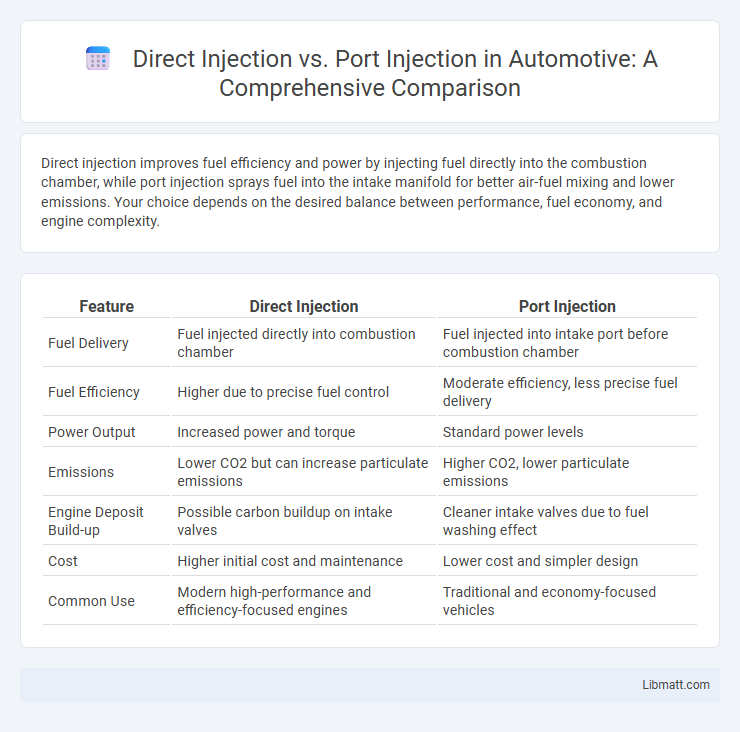

Direct injection improves fuel efficiency and power by injecting fuel directly into the combustion chamber, while port injection sprays fuel into the intake manifold for better air-fuel mixing and lower emissions. Your choice depends on the desired balance between performance, fuel economy, and engine complexity.

Table of Comparison

| Feature | Direct Injection | Port Injection |

|---|---|---|

| Fuel Delivery | Fuel injected directly into combustion chamber | Fuel injected into intake port before combustion chamber |

| Fuel Efficiency | Higher due to precise fuel control | Moderate efficiency, less precise fuel delivery |

| Power Output | Increased power and torque | Standard power levels |

| Emissions | Lower CO2 but can increase particulate emissions | Higher CO2, lower particulate emissions |

| Engine Deposit Build-up | Possible carbon buildup on intake valves | Cleaner intake valves due to fuel washing effect |

| Cost | Higher initial cost and maintenance | Lower cost and simpler design |

| Common Use | Modern high-performance and efficiency-focused engines | Traditional and economy-focused vehicles |

Introduction to Fuel Injection Systems

Fuel injection systems, including direct injection and port injection, play a critical role in delivering fuel to the engine for optimal combustion performance. Direct injection injects fuel directly into the combustion chamber, improving fuel atomization and enabling precise control over the air-fuel mixture, which enhances power output and fuel efficiency. Port injection delivers fuel into the intake manifold before it enters the combustion chamber, offering better air-fuel mixing and lower emissions at lower engine loads.

What is Direct Injection?

Direct injection is a fuel delivery system that injects fuel directly into the combustion chamber of each cylinder, enhancing combustion efficiency and power output. This method allows for precise control of fuel quantity and timing, resulting in improved fuel economy and reduced emissions. Unlike port injection, direct injection provides better atomization of fuel, enabling a higher compression ratio and increased engine performance.

What is Port Injection?

Port injection is a fuel delivery system where fuel is injected into the intake ports just before entering the combustion chamber, allowing precise fuel atomization and improved air-fuel mixture. Unlike direct injection, which sprays fuel directly into the cylinder, port injection promotes cleaner combustion and reduces carbon buildup on intake valves. Your engine efficiency and emissions can benefit from port injection's ability to optimize fuel distribution in various operating conditions.

Key Differences Between Direct and Port Injection

Direct injection delivers fuel directly into the combustion chamber, enabling precise control and higher compression ratios for improved power and fuel efficiency. Port injection sprays fuel into the intake manifold, mixing with air before entering the combustion chamber, which reduces carbon buildup on intake valves and ensures better cold-start performance. Key differences include injection location, fuel atomization timing, and impact on emissions, with direct injection providing enhanced performance but requiring more complex emission controls.

Performance Comparison: Direct vs Port

Direct injection delivers fuel directly into the combustion chamber, improving combustion efficiency and power output by achieving optimal air-fuel mixing and reducing fuel evaporation losses. Port injection sprays fuel into the intake manifold, promoting better air-fuel mixing at lower engine speeds but typically resulting in lower peak power compared to direct injection. Your choice between direct and port injection impacts engine performance, with direct injection offering enhanced power and fuel efficiency for high-performance applications.

Efficiency and Fuel Economy

Direct injection improves fuel economy by delivering fuel directly into the combustion chamber, enabling precise control over the air-fuel mixture and reducing fuel wastage. Port injection sprays fuel into the intake ports, promoting better mixing with air and cleaner intake valves but generally results in slightly lower efficiency compared to direct injection. Vehicles with direct injection systems typically achieve higher thermal efficiency and reduced fuel consumption under various driving conditions.

Emissions Impact and Environmental Considerations

Direct injection engines typically produce lower CO2 emissions due to improved fuel efficiency but may emit higher levels of particulate matter (PM) and nitrogen oxides (NOx) compared to port injection systems. Port injection engines generally have cleaner combustion with reduced PM and NOx emissions but can result in higher overall fuel consumption and CO2 output. Understanding these trade-offs helps you balance environmental impact and regulatory compliance when choosing engine technology.

Maintenance and Reliability Factors

Direct injection systems often require more frequent maintenance due to potential issues like carbon buildup on intake valves, impacting long-term reliability compared to port injection. Port injection generally offers easier maintenance with fewer risks of clogging and is known for consistent performance and durability. Understanding these differences helps you make informed decisions about engine care and reliability management.

Applications and Industry Trends

Direct injection technology is increasingly adopted in high-performance and commercial vehicles due to its superior fuel efficiency and reduced emissions, making it a preferred choice in the automotive industry. Port injection remains prevalent in smaller engines and hybrid systems where cost-effectiveness and simpler design are prioritized, maintaining its relevance in light-duty applications and certain market segments. Your decision between these systems should consider evolving industry trends favoring direct injection for stricter emission standards and enhanced power delivery in modern vehicles.

Future of Fuel Injection Technology

Direct injection offers precise fuel delivery, enhancing engine efficiency and reducing emissions compared to port injection systems. As automotive technology advances, future fuel injection systems are expected to integrate smart sensors and AI-driven controls, optimizing performance in real-time. Your vehicle's fuel injection system will likely evolve to combine the benefits of both direct and port injection, maximizing power while minimizing environmental impact.

Direct injection vs Port injection Infographic

libmatt.com

libmatt.com