Coil-on-plug ignition systems deliver precise, individual spark timing directly to each cylinder, improving efficiency and reducing misfires compared to distributor ignition systems, which rely on a centralized distributor to route spark through a single coil and rotor. Your vehicle benefits from enhanced performance, simplified maintenance, and better fuel economy with coil-on-plug technology due to its advanced electronic control and reduced mechanical wear.

Table of Comparison

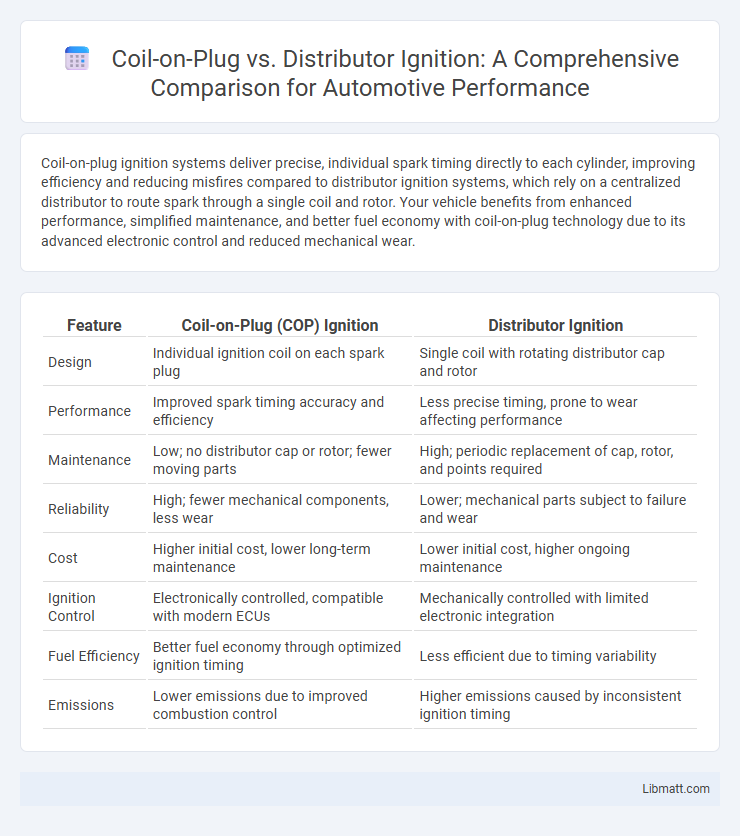

| Feature | Coil-on-Plug (COP) Ignition | Distributor Ignition |

|---|---|---|

| Design | Individual ignition coil on each spark plug | Single coil with rotating distributor cap and rotor |

| Performance | Improved spark timing accuracy and efficiency | Less precise timing, prone to wear affecting performance |

| Maintenance | Low; no distributor cap or rotor; fewer moving parts | High; periodic replacement of cap, rotor, and points required |

| Reliability | High; fewer mechanical components, less wear | Lower; mechanical parts subject to failure and wear |

| Cost | Higher initial cost, lower long-term maintenance | Lower initial cost, higher ongoing maintenance |

| Ignition Control | Electronically controlled, compatible with modern ECUs | Mechanically controlled with limited electronic integration |

| Fuel Efficiency | Better fuel economy through optimized ignition timing | Less efficient due to timing variability |

| Emissions | Lower emissions due to improved combustion control | Higher emissions caused by inconsistent ignition timing |

Introduction to Ignition Systems

Coil-on-plug ignition systems deliver a dedicated ignition coil directly to each spark plug, enhancing combustion efficiency and reducing energy loss compared to traditional distributor ignition systems. Distributor ignition relies on a single coil and a rotating distributor to channel high voltage to each spark plug, which can lead to wear and timing inconsistencies over time. Your engine's performance and maintenance are optimized with coil-on-plug technology, benefiting from precise spark timing and reduced mechanical complexity.

What is Coil-on-Plug Ignition?

Coil-on-plug ignition is a modern ignition system where each spark plug has its own individual ignition coil mounted directly on top, eliminating the need for a distributor and spark plug wires. This design ensures precise ignition timing and stronger spark delivery, improving engine efficiency and reducing misfires compared to traditional distributor ignition systems. By directly controlling each coil electronically, coil-on-plug systems enhance reliability and lower maintenance requirements.

How Distributor Ignition Works

Distributor ignition uses a rotating distributor cam connected to the engine's camshaft to deliver high voltage from the ignition coil to each spark plug in sequence. Mechanical or electronic contacts inside the distributor open and close to control the timing of the spark, ensuring ignition occurs at the precise moment during the combustion cycle. The distributor shaft's rotation synchronizes spark delivery with engine speed and load, but mechanical wear and timing drift can affect performance over time.

Key Differences Between Coil-on-Plug and Distributor Ignition

Coil-on-plug ignition systems eliminate the need for a distributor by placing individual ignition coils directly on each spark plug, enhancing ignition precision and reducing energy loss. Distributor ignition systems rely on a central distributor to route high voltage to spark plugs via a rotor and cap, resulting in more mechanical wear and potential timing inaccuracies. Coil-on-plug setups provide improved spark timing control, higher reliability, and lower maintenance compared to traditional distributor-based ignition systems.

Performance Comparison: Spark Efficiency and Timing

Coil-on-plug ignition systems deliver more precise spark timing and higher spark energy directly to each cylinder, improving combustion efficiency compared to traditional distributor ignition systems that rely on a centralized rotor and cap, which can cause timing inconsistencies and energy loss. The elimination of spark plug wires in coil-on-plug setups reduces electrical interference and misfires, enhancing overall engine performance and fuel economy. Your vehicle benefits from faster ignition response and more accurate spark control, resulting in smoother acceleration and increased power output.

Maintenance Requirements and Longevity

Coil-on-plug ignition systems require less frequent maintenance compared to traditional distributor ignition systems, as they eliminate the need for components like distributor caps, rotors, and spark plug wires that are prone to wear and corrosion. The longevity of coil-on-plug systems is enhanced by their direct spark delivery to each cylinder, reducing energy loss and heat exposure, which often leads to extended spark plug life and fewer ignition faults. In contrast, distributor ignition systems typically demand regular inspections, part replacements, and timing adjustments due to mechanical wear and environmental factors affecting the distributor mechanism.

Impact on Fuel Efficiency and Emissions

Coil-on-plug ignition systems deliver precise, individual sparks directly to each cylinder, enhancing combustion efficiency and reducing unburnt fuel, which leads to improved fuel economy and lower emissions. Distributor ignition systems distribute spark to all cylinders via a mechanical rotor, which can cause inconsistent spark timing and reduced combustion efficiency, resulting in higher fuel consumption and increased pollutant output. Optimizing your ignition system with coil-on-plug technology can significantly improve engine performance and minimize environmental impact.

Cost and Installation Considerations

Coil-on-plug ignition systems usually have higher upfront costs due to individual ignition coils for each cylinder but simplify installation by eliminating the distributor and associated wiring. Distributor ignition systems are generally less expensive initially and easier to replace but require more maintenance and complex wiring harnesses. Installing coil-on-plug setups can reduce long-term service costs and improve reliability despite the initial investment.

Reliability and Common Failure Points

Coil-on-plug ignition systems offer higher reliability due to their individual coil design, which reduces the risk of single-point failures common in distributor ignition systems, such as worn distributor caps and rotors. Common failure points in coil-on-plug setups include coil pack faults and damaged spark plug boots, while distributor systems often suffer from moisture intrusion and mechanical wear. The elimination of moving parts in coil-on-plug designs increases durability and reduces maintenance needs compared to traditional distributor ignition systems.

Which Ignition System is Best for Your Vehicle?

Coil-on-plug ignition systems provide precise spark timing and improved fuel efficiency by delivering spark directly to each cylinder, reducing energy loss common in distributor ignition systems. Distributor ignition systems, while simpler and often less expensive, are prone to wear and less accurate spark distribution, making them less suitable for modern vehicles with advanced engine management. For optimal performance, fuel economy, and reliability, especially in newer vehicles, coil-on-plug ignition is generally the best choice.

coil-on-plug vs distributor ignition Infographic

libmatt.com

libmatt.com