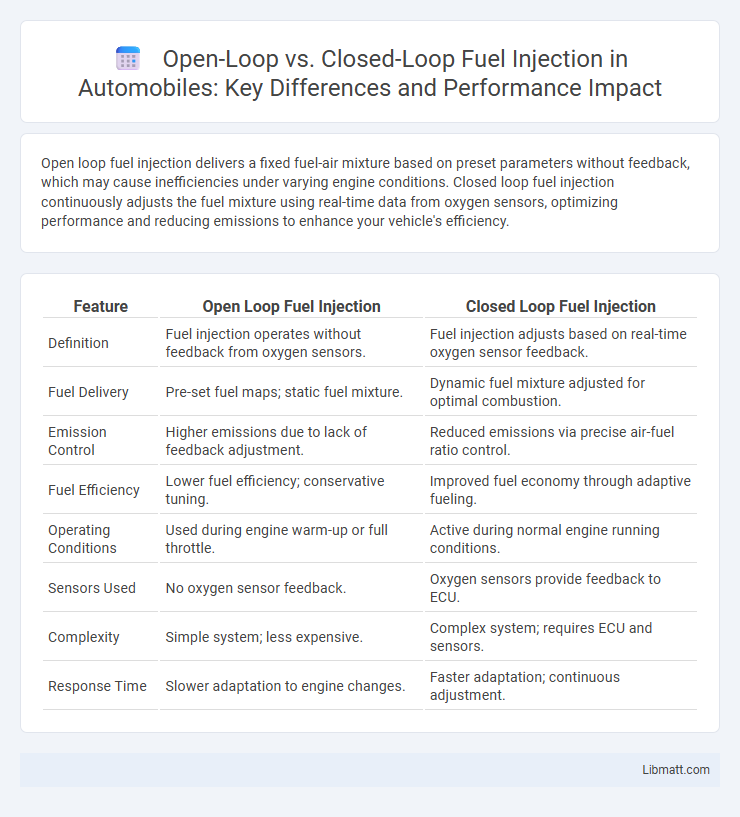

Open loop fuel injection delivers a fixed fuel-air mixture based on preset parameters without feedback, which may cause inefficiencies under varying engine conditions. Closed loop fuel injection continuously adjusts the fuel mixture using real-time data from oxygen sensors, optimizing performance and reducing emissions to enhance your vehicle's efficiency.

Table of Comparison

| Feature | Open Loop Fuel Injection | Closed Loop Fuel Injection |

|---|---|---|

| Definition | Fuel injection operates without feedback from oxygen sensors. | Fuel injection adjusts based on real-time oxygen sensor feedback. |

| Fuel Delivery | Pre-set fuel maps; static fuel mixture. | Dynamic fuel mixture adjusted for optimal combustion. |

| Emission Control | Higher emissions due to lack of feedback adjustment. | Reduced emissions via precise air-fuel ratio control. |

| Fuel Efficiency | Lower fuel efficiency; conservative tuning. | Improved fuel economy through adaptive fueling. |

| Operating Conditions | Used during engine warm-up or full throttle. | Active during normal engine running conditions. |

| Sensors Used | No oxygen sensor feedback. | Oxygen sensors provide feedback to ECU. |

| Complexity | Simple system; less expensive. | Complex system; requires ECU and sensors. |

| Response Time | Slower adaptation to engine changes. | Faster adaptation; continuous adjustment. |

Introduction to Fuel Injection Systems

Fuel injection systems control the delivery of fuel to an engine, optimizing combustion efficiency and performance. Open loop fuel injection operates without feedback from oxygen sensors, delivering a fixed fuel mixture based on preset parameters. Closed loop fuel injection constantly adjusts the air-fuel ratio using real-time sensor data, ensuring better fuel economy and reduced emissions for Your vehicle.

What is Open Loop Fuel Injection?

Open Loop Fuel Injection operates without feedback from the oxygen sensor, delivering a predetermined air-fuel mixture based on engine temperature and throttle position sensors. This mode is typically used during engine warm-up or under heavy acceleration when the system prioritizes performance over fuel efficiency. Your vehicle relies on this open loop strategy to ensure immediate throttle response before switching to closed loop for optimal emissions control.

How Closed Loop Fuel Injection Works

Closed Loop Fuel Injection continuously monitors oxygen levels in the exhaust using an oxygen sensor, allowing the engine control unit (ECU) to adjust the air-fuel mixture in real-time for optimal combustion efficiency. This feedback system maintains a precise stoichiometric balance, enhancing fuel economy while reducing harmful emissions. The ECU processes sensor data to dynamically modulate fuel delivery, ensuring consistent engine performance under varying operating conditions.

Key Differences Between Open and Closed Loop

Open loop fuel injection operates without feedback, delivering a fixed air-fuel mixture based on preset parameters, optimizing performance during engine warm-up or full throttle. Closed loop fuel injection continuously adjusts the air-fuel ratio using real-time data from an oxygen sensor, ensuring optimal combustion efficiency and reduced emissions. Key differences include open loop's reliance on default mappings versus closed loop's adaptive control to maintain stoichiometric balance.

Advantages of Open Loop Fuel Injection

Open loop fuel injection systems offer faster engine response by delivering a predetermined air-fuel mixture without waiting for sensor feedback, which enhances performance during cold starts and rapid acceleration. These systems are mechanically simpler and less expensive to manufacture and maintain due to the absence of feedback sensors like oxygen sensors. Open loop fuel injection also avoids potential errors from faulty sensors, ensuring consistent fuel delivery under specific operating conditions.

Benefits of Closed Loop Fuel Injection

Closed loop fuel injection delivers precise air-fuel mixture control by continuously monitoring oxygen sensors in the exhaust system, enhancing engine performance and fuel efficiency. This system reduces harmful emissions by adjusting fuel delivery in real-time to match varying operating conditions, promoting environmental compliance. Improved drivability and smoother engine operation result from the constant feedback provided, ensuring optimal combustion under diverse load and temperature ranges.

Impact on Engine Performance and Efficiency

Closed loop fuel injection continuously adjusts fuel delivery based on real-time feedback from oxygen sensors, optimizing air-fuel mixture for improved engine performance and fuel efficiency. Open loop systems use preset fuel maps without sensor feedback, often resulting in less precise fuel delivery and reduced efficiency, especially during varying engine conditions. Closed loop systems enhance combustion stability, lower emissions, and maximize power output by maintaining the ideal stoichiometric ratio.

Common Applications in Automotive Industry

Open loop fuel injection systems are commonly used in older vehicles and basic engine designs where sensor feedback is limited, providing fixed fuel delivery based on predefined parameters. Closed loop fuel injection systems dominate modern automotive applications, leveraging real-time data from oxygen sensors to continuously adjust fuel mixture for optimal performance and emissions control. Your vehicle's efficiency and emissions compliance heavily rely on the precision of closed loop systems, especially in contemporary engines with advanced electronic control units (ECUs).

Troubleshooting and Maintenance Considerations

Troubleshooting open loop fuel injection systems involves checking sensors like the throttle position sensor and engine temperature sensor since these systems rely on preset fuel maps without real-time feedback. Closed loop fuel injection systems require diagnostics of the oxygen sensor and the electronic control unit (ECU) as they continuously adjust fuel delivery based on exhaust feedback for optimal performance. Maintenance for closed loop systems typically involves regular oxygen sensor inspections and ECU software updates, whereas open loop systems primarily need sensor calibration and fuel injector cleaning.

Choosing Between Open Loop and Closed Loop Systems

Choosing between open loop and closed loop fuel injection systems depends on the balance between performance and efficiency needs. Open loop systems provide consistent fuel delivery based on preset parameters, ideal for high-performance or racing engines where precise control is necessary. Closed loop systems use feedback from oxygen sensors to optimize the air-fuel mixture in real-time, enhancing fuel economy and reducing emissions in everyday driving conditions.

Open Loop vs Closed Loop Fuel Injection Infographic

libmatt.com

libmatt.com