Thermosiphon cooling relies on natural convection to circulate coolant without a pump, making it energy-efficient and low-maintenance for systems with modest heat dissipation needs. Your choice depends on whether you prioritize simplicity and reliability or require more consistent and controlled cooling performance provided by forced circulation systems.

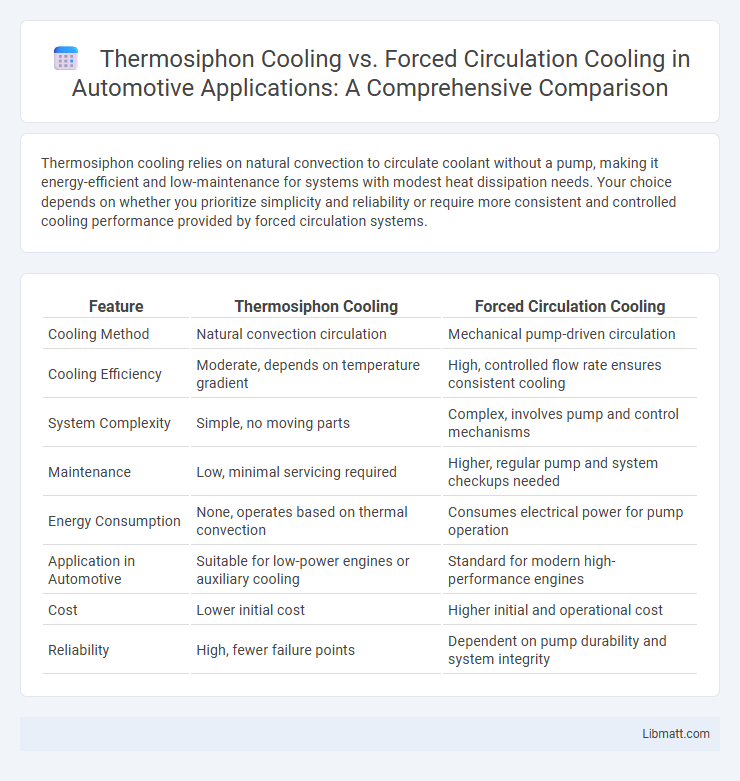

Table of Comparison

| Feature | Thermosiphon Cooling | Forced Circulation Cooling |

|---|---|---|

| Cooling Method | Natural convection circulation | Mechanical pump-driven circulation |

| Cooling Efficiency | Moderate, depends on temperature gradient | High, controlled flow rate ensures consistent cooling |

| System Complexity | Simple, no moving parts | Complex, involves pump and control mechanisms |

| Maintenance | Low, minimal servicing required | Higher, regular pump and system checkups needed |

| Energy Consumption | None, operates based on thermal convection | Consumes electrical power for pump operation |

| Application in Automotive | Suitable for low-power engines or auxiliary cooling | Standard for modern high-performance engines |

| Cost | Lower initial cost | Higher initial and operational cost |

| Reliability | High, fewer failure points | Dependent on pump durability and system integrity |

Introduction to Cooling Systems

Thermosiphon cooling relies on natural convection to circulate the coolant without the need for a mechanical pump, making it energy-efficient and low-maintenance for systems with moderate heat dissipation. Forced circulation cooling employs pumps to actively move coolant through the system, providing greater control over temperature regulation and suitability for high-performance or high-heat applications. Both cooling methods are essential in various industrial and automotive applications, with thermosiphon favored for simplicity and forced circulation chosen for enhanced cooling capacity.

Overview of Thermosiphon Cooling

Thermosiphon cooling relies on natural convection where fluid circulation is driven by density differences caused by temperature gradients, eliminating the need for mechanical pumps. This passive cooling method is energy-efficient and ideal for low to moderate heat dissipation applications, often used in solar water heaters and computer cooling systems. Its simplicity reduces maintenance and operational costs but limits performance under high heat loads compared to forced circulation cooling.

Fundamentals of Forced Circulation Cooling

Forced circulation cooling relies on pumps to actively circulate the coolant through the system, ensuring efficient heat transfer even under high thermal loads. This method provides precise temperature control by maintaining consistent fluid flow rates, unlike thermosiphon cooling, which depends on natural convection. Your system benefits from enhanced cooling performance and faster response times through the controlled flow enabled by forced circulation.

Key Differences Between Thermosiphon and Forced Circulation

Thermosiphon cooling relies on natural convection driven by temperature-induced density differences, enabling fluid circulation without pumps, whereas forced circulation cooling employs mechanical pumps to actively move the coolant through the system. The efficiency of thermosiphon systems depends on gravity and fluid properties, limiting their use to vertical or inclined setups, while forced circulation systems offer greater control and versatility for diverse orientations and higher heat transfer rates. Maintenance for thermosiphon systems is generally simpler due to fewer moving parts, compared to the more complex and energy-intensive forced circulation cooling requiring regular pump servicing and power consumption.

Energy Efficiency Comparison

Thermosiphon cooling relies on natural convection currents to circulate coolant, resulting in lower energy consumption due to the absence of mechanical pumps, making it highly energy-efficient for systems with moderate heat loads. Forced circulation cooling uses pumps to actively circulate the coolant, which increases energy usage but provides superior heat transfer rates and precise temperature control for high-demand applications. Energy efficiency in thermosiphon systems generally surpasses forced circulation under steady-state conditions, while forced circulation excels when rapid heat dissipation and system responsiveness are critical.

Performance and Reliability Analysis

Thermosiphon cooling relies on natural convection to circulate coolant, resulting in lower energy consumption and reduced mechanical failure rates, which enhances reliability in systems without moving parts. Forced circulation cooling employs pumps to actively move coolant, offering superior heat transfer performance and precise temperature control, particularly in high heat flux applications. Performance metrics favor forced circulation for rapid cooling capacity, whereas thermosiphon systems are preferred for long-term reliability due to minimal maintenance and inherent fail-safe operation.

Installation and Maintenance Requirements

Thermosiphon cooling systems require minimal installation effort since they operate without pumps, relying on natural convection, which reduces maintenance needs and lowers long-term operational costs. Forced circulation cooling systems involve more complex installation due to the inclusion of pumps and controllers, necessitating regular maintenance to ensure pump reliability and system efficiency. The simplicity of thermosiphon setups makes them ideal for locations with limited access or technical support, while forced circulation systems are better suited for applications demanding precise temperature control despite higher upkeep.

Cost Considerations for Both Systems

Thermosiphon cooling systems offer lower initial investment and minimal operational costs due to their reliance on natural convection without pumps or complex controls. Forced circulation cooling, while more expensive to install and maintain because of its pumps and power consumption, provides precise temperature control and higher cooling efficiency. Evaluating your budget and performance requirements will help determine which cooling method delivers the best cost-performance balance for your application.

Best Applications and Use Cases

Thermosiphon cooling excels in passive systems like solar water heaters and small-scale electronics where natural convection provides reliable heat dissipation without external power. Forced circulation cooling is ideal for industrial processes, automotive engines, and large HVAC systems requiring precise temperature control and rapid heat transfer via pumps or fans. Your choice depends on application scale, energy availability, and cooling performance requirements.

Conclusion: Choosing the Right Cooling System

Thermosiphon cooling offers a passive, energy-efficient solution relying on natural convection to circulate coolant without pumps, ideal for systems with modest heat loads and where power savings are prioritized. Forced circulation cooling uses mechanical pumps to ensure consistent and controlled flow, providing superior performance for high heat dissipation requirements and applications demanding precise temperature management. Selecting the right cooling system depends on factors such as heat load, energy efficiency goals, maintenance capabilities, and system complexity to achieve optimal thermal management.

Thermosiphon Cooling vs Forced Circulation Cooling Infographic

libmatt.com

libmatt.com