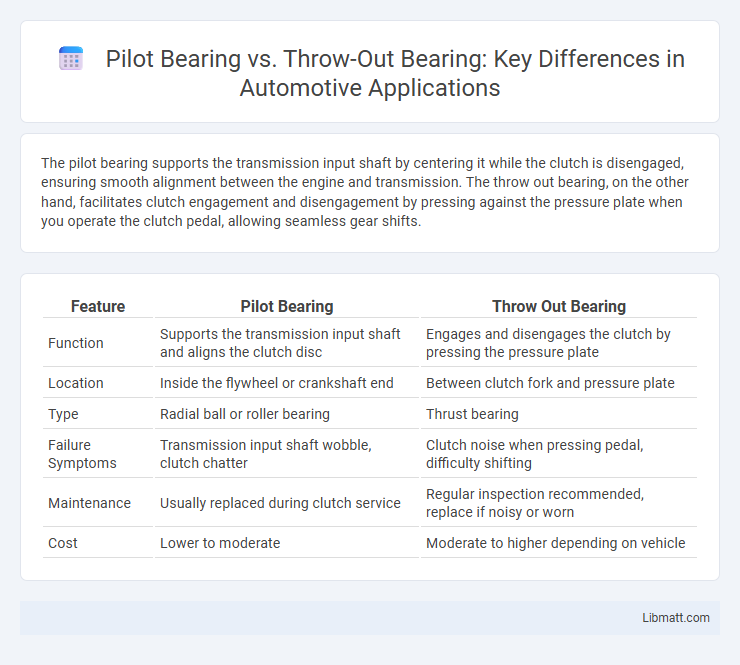

The pilot bearing supports the transmission input shaft by centering it while the clutch is disengaged, ensuring smooth alignment between the engine and transmission. The throw out bearing, on the other hand, facilitates clutch engagement and disengagement by pressing against the pressure plate when you operate the clutch pedal, allowing seamless gear shifts.

Table of Comparison

| Feature | Pilot Bearing | Throw Out Bearing |

|---|---|---|

| Function | Supports the transmission input shaft and aligns the clutch disc | Engages and disengages the clutch by pressing the pressure plate |

| Location | Inside the flywheel or crankshaft end | Between clutch fork and pressure plate |

| Type | Radial ball or roller bearing | Thrust bearing |

| Failure Symptoms | Transmission input shaft wobble, clutch chatter | Clutch noise when pressing pedal, difficulty shifting |

| Maintenance | Usually replaced during clutch service | Regular inspection recommended, replace if noisy or worn |

| Cost | Lower to moderate | Moderate to higher depending on vehicle |

Introduction to Pilot Bearings and Throw Out Bearings

Pilot bearings are small components located at the engine's crankshaft to support the transmission input shaft, reducing friction during clutch engagement. Throw out bearings, also known as clutch release bearings, are positioned within the clutch assembly to disengage the pressure plate when the clutch pedal is pressed. Both bearings play crucial roles in ensuring smooth gear shifts and preventing drivetrain damage in manual transmission vehicles.

Function and Importance of Pilot Bearings

Pilot bearings support the transmission input shaft, ensuring smooth alignment with the engine crankshaft for efficient power transfer and reducing wear on the transmission components. This small but critical component prevents vibration and misalignment during clutch engagement, enhancing the overall performance and longevity of your vehicle's drivetrain. Understanding the function and importance of pilot bearings helps maintain transmission health and avoid costly repairs.

Function and Role of Throw Out Bearings

Throw out bearings play a crucial role in the clutch system by disengaging the engine from the transmission when the clutch pedal is pressed, allowing smooth gear shifts. They work by pressing against the pressure plate's diaphragm spring, reducing friction and wear on other clutch components. Proper functioning of throw out bearings ensures efficient power transfer and prevents clutch slippage or noise during operation.

Key Differences Between Pilot and Throw Out Bearings

Pilot bearings support the transmission input shaft by centering it in the flywheel, ensuring smooth rotation and alignment during engine operation, whereas throw out bearings engage and disengage the clutch by pressing against the pressure plate when you press the clutch pedal. The pilot bearing is typically a small, stationary bearing located in the crankshaft or flywheel, while the throw out bearing is a movable component that directly interacts with the clutch release mechanism. Understanding these key differences helps maintain your vehicle's clutch system efficiency and longevity.

Symptoms of a Failing Pilot Bearing

A failing pilot bearing often causes noticeable vibrations and resistance when starting or shifting gears, leading to difficulty in smooth clutch operation. You may hear grinding or squealing noises coming from the transmission area when the clutch is engaged or released. Early detection of these symptoms helps prevent further damage to the transmission system and costly repairs.

Signs of a Bad Throw Out Bearing

Signs of a bad throw out bearing include a loud grinding or squealing noise when depressing the clutch pedal, difficulty shifting gears, and a vibrating clutch pedal. The throw out bearing often fails due to wear and tear from constant pressure against the pressure plate release fingers. Ignoring these symptoms can lead to clutch engagement issues and potential damage to the transmission system.

Replacement Process: Pilot Bearing vs. Throw Out Bearing

The replacement process of the pilot bearing involves removing the transmission to access the rear of the engine's crankshaft, where the bearing supports the input shaft, requiring precise alignment during installation to prevent drivetrain damage. In contrast, replacing the throw out bearing is typically more straightforward, involving disassembling the clutch release mechanism and sliding out the worn bearing from the clutch fork or release arm without the need to remove the transmission entirely. Understanding the distinct procedures ensures Your clutch system components are replaced accurately, maintaining optimal performance and preventing premature failure.

Maintenance Tips for Prolonged Bearing Life

Regularly inspect both the pilot bearing and throw out bearing for signs of wear or noise, as early detection can prevent costly transmission damage. Apply manufacturer-recommended lubricants to reduce friction and heat buildup, extending the lifespan of each bearing. Ensure proper alignment and adjustment during clutch installation to avoid uneven stress and premature failure.

Common Causes of Bearing Failure

Pilot bearing failure often results from insufficient lubrication, contamination, or misalignment during installation, leading to overheating and premature wear. Throw out bearing failure commonly occurs due to constant friction, excessive clutch pedal pressure, or lack of proper maintenance, causing noise, vibration, and clutch disengagement issues. Both bearing types are critical for smooth clutch operation and require regular inspection to prevent costly drivetrain damage.

Choosing the Right Bearing for Your Vehicle

Choosing the right bearing for your vehicle requires understanding the distinct roles of the pilot bearing and throw-out bearing in the clutch system. The pilot bearing supports the transmission input shaft, ensuring smooth rotation and alignment, while the throw-out bearing engages and disengages the clutch, allowing for seamless gear changes. Selecting the correct bearing based on your vehicle's make, model, and driving conditions ensures optimal performance and prevents premature wear.

Pilot Bearing vs Throw Out Bearing Infographic

libmatt.com

libmatt.com