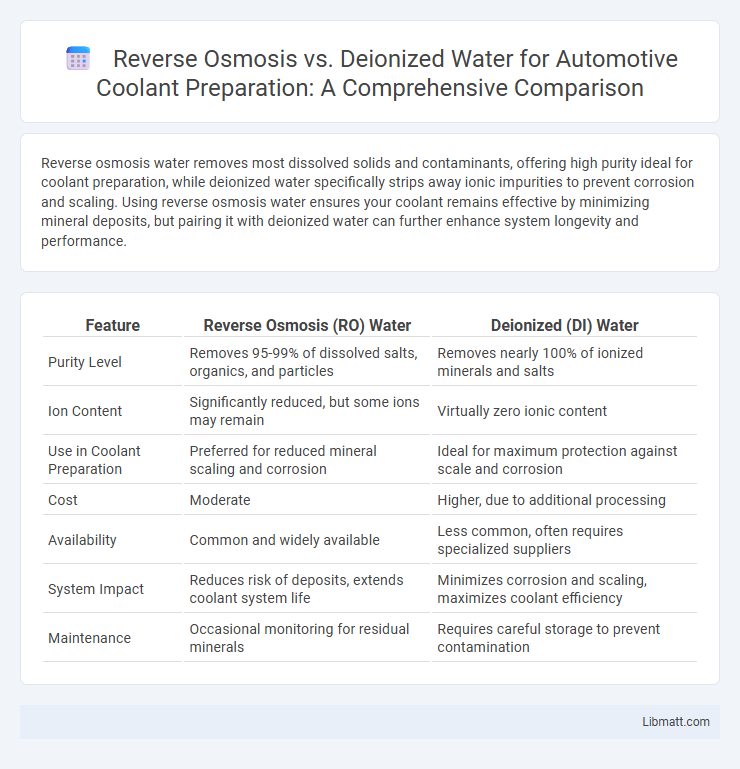

Reverse osmosis water removes most dissolved solids and contaminants, offering high purity ideal for coolant preparation, while deionized water specifically strips away ionic impurities to prevent corrosion and scaling. Using reverse osmosis water ensures your coolant remains effective by minimizing mineral deposits, but pairing it with deionized water can further enhance system longevity and performance.

Table of Comparison

| Feature | Reverse Osmosis (RO) Water | Deionized (DI) Water |

|---|---|---|

| Purity Level | Removes 95-99% of dissolved salts, organics, and particles | Removes nearly 100% of ionized minerals and salts |

| Ion Content | Significantly reduced, but some ions may remain | Virtually zero ionic content |

| Use in Coolant Preparation | Preferred for reduced mineral scaling and corrosion | Ideal for maximum protection against scale and corrosion |

| Cost | Moderate | Higher, due to additional processing |

| Availability | Common and widely available | Less common, often requires specialized suppliers |

| System Impact | Reduces risk of deposits, extends coolant system life | Minimizes corrosion and scaling, maximizes coolant efficiency |

| Maintenance | Occasional monitoring for residual minerals | Requires careful storage to prevent contamination |

Introduction to Coolant Water Preparation

Reverse osmosis (RO) produces highly purified water by removing dissolved solids, chlorine, and organic contaminants through a semipermeable membrane, making it ideal for coolant preparation due to minimal mineral content. Deionized (DI) water eliminates ionic impurities via ion-exchange resins, ensuring extremely low conductivity and preventing scale or corrosion in cooling systems. Your choice between RO and DI water impacts coolant longevity and system efficiency, with both methods providing essential purity to maintain optimal thermal performance.

Understanding Reverse Osmosis Water

Reverse osmosis water is produced by forcing water through a semipermeable membrane that removes 95-99% of dissolved salts, organics, and contaminants, making it highly purified. It is preferred for coolant preparation due to its low mineral content, which helps prevent scale buildup and corrosion in cooling systems. Unlike deionized water, reverse osmosis water retains some dissolved gases, requiring additional treatment depending on the application.

What Is Deionized Water?

Deionized water is purified through a process that removes mineral ions such as calcium, sodium, and chloride, resulting in water with minimal electrical conductivity. This ultra-pure water is ideal for coolant preparation because it prevents mineral buildup and corrosion inside the cooling system. Using deionized water ensures your coolant maintains optimal performance and longevity by avoiding contaminants that can degrade engine components.

Key Differences: RO vs DI Water

Reverse osmosis (RO) water is produced by forcing water through a semipermeable membrane, effectively removing most dissolved solids, bacteria, and impurities, while deionized (DI) water is created by exchanging ions, specifically targeting mineral ions like calcium and magnesium. RO water typically contains fewer organic compounds and bacteria than DI water, but DI water provides higher purity by removing all charged particles, making it ideal for coolant preparation where mineral content must be minimized to prevent corrosion and scaling. Your choice between RO and DI water depends on the required purity level, with DI water offering superior ion removal crucial for maintaining optimal coolant system performance.

Water Purity and Contaminant Removal

Reverse osmosis water provides high purity by effectively removing 95-99% of dissolved salts, organic matter, and bacteria, ensuring minimal contaminants in your coolant preparation. Deionized water excels in eliminating ionic impurities through ion exchange resins but may still contain uncharged organic compounds or microbes if not further treated. Choosing reverse osmosis or deionized water impacts coolant performance, with reverse osmosis offering broader contaminant removal for enhanced purity.

Impact on Coolant System Performance

Reverse osmosis water contains fewer dissolved solids compared to tap water, reducing the risk of scale buildup and corrosion in coolant systems, thus ensuring optimal heat transfer and prolonging system lifespan. Deionized water removes most ionic contaminants, offering even higher purity that minimizes conductivity and further prevents electrochemical reactions detrimental to coolant stability. Using either water type enhances coolant system performance by reducing contamination, but deionized water typically provides superior protection for sensitive engine components and advanced cooling technologies.

Corrosion Risks and Protection

Reverse osmosis water contains residual minerals that can reduce corrosion risks by maintaining a balanced conductivity and alkalinity, providing better protection for metal components in coolant systems. Deionized water, while purer, lacks essential ions that form protective oxide layers, increasing the risk of corrosion unless corrosion inhibitors are added. Proper coolant preparation involves balancing water purity with corrosion control additives to ensure long-term protection of engine and cooling system metals.

Cost and Maintenance Considerations

Reverse osmosis (RO) systems for coolant preparation involve moderate upfront costs and require periodic maintenance such as membrane replacement every 2-3 years and regular filter changes, ensuring consistent water purity at a reasonable expense. Deionized (DI) water setups tend to have lower initial costs but incur ongoing expenses for resin replacement and regeneration chemicals, increasing maintenance frequency and operational costs over time. You should weigh the long-term cost efficiency and maintenance demands between RO systems' durability and DI systems' consumable dependencies to optimize coolant water quality economically.

Industry Recommendations and Best Practices

Industry recommendations favor reverse osmosis (RO) water for coolant preparation due to its effective removal of dissolved solids and impurities, enhancing system longevity and performance. Deionized (DI) water, while free of ionic contaminants, may not eliminate all organic compounds and can be more costly, limiting its use to specialized applications. For your coolant prep, using RO water aligns with best practices by balancing purity, cost-efficiency, and operational reliability in industrial standards.

Conclusion: Choosing the Right Water for Coolant Preparation

Reverse osmosis water offers high purity by effectively removing dissolved solids and contaminants, making it suitable for precise coolant preparation. Deionized water excels in eliminating ionic impurities, reducing conductivity which helps prevent corrosion in cooling systems. Your choice depends on the specific quality requirements of the coolant and system sensitivity, with reverse osmosis generally preferred for balanced purity and deionization favored for ultra-low mineral content.

Reverse osmosis vs Deionized water (for coolant prep) Infographic

libmatt.com

libmatt.com