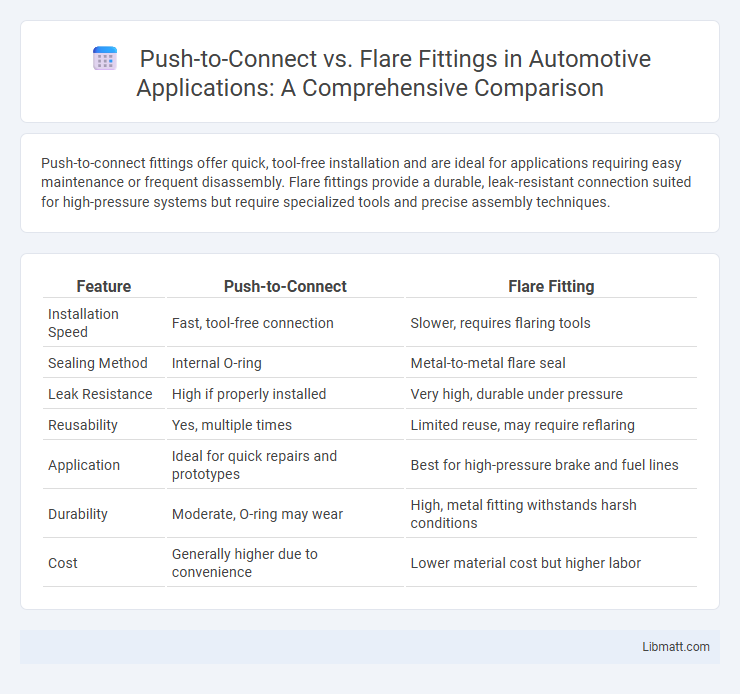

Push-to-connect fittings offer quick, tool-free installation and are ideal for applications requiring easy maintenance or frequent disassembly. Flare fittings provide a durable, leak-resistant connection suited for high-pressure systems but require specialized tools and precise assembly techniques.

Table of Comparison

| Feature | Push-to-Connect | Flare Fitting |

|---|---|---|

| Installation Speed | Fast, tool-free connection | Slower, requires flaring tools |

| Sealing Method | Internal O-ring | Metal-to-metal flare seal |

| Leak Resistance | High if properly installed | Very high, durable under pressure |

| Reusability | Yes, multiple times | Limited reuse, may require reflaring |

| Application | Ideal for quick repairs and prototypes | Best for high-pressure brake and fuel lines |

| Durability | Moderate, O-ring may wear | High, metal fitting withstands harsh conditions |

| Cost | Generally higher due to convenience | Lower material cost but higher labor |

Introduction to Push-to-Connect and Flare Fittings

Push-to-connect fittings provide a quick, tool-free connection ideal for fluid and air systems, ensuring a secure, leak-free seal using internal O-rings. Flare fittings rely on a tapered, flared tube end compressed against a matching fitting, offering high-pressure resistance commonly used in gas and refrigeration applications. Your choice between push-to-connect and flare fittings depends on factors like installation speed, pressure requirements, and system compatibility.

Key Differences Between Push-to-Connect and Flare Fittings

Push-to-connect fittings offer quick, tool-free installation and are ideal for applications requiring frequent disassembly or tight spaces, whereas flare fittings rely on a flared tube end and threaded connection, providing a secure, vibration-resistant seal suited for high-pressure systems. Push-to-connect fittings use internal O-rings to create a watertight seal, while flare fittings depend on metal-to-metal contact between the flared tubing and fitting. Compatibility with different pipe materials varies; push-to-connect works well with copper, PEX, and CPVC, while flare fittings are primarily used with copper tubing.

Ease of Installation: Push-to-Connect vs Flare Fittings

Push-to-connect fittings significantly reduce installation time by allowing quick, tool-free connections, ideal for both professionals and DIY enthusiasts. Flare fittings require precise alignment, wrench tightening, and thread sealing, demanding more skill and time to ensure leak-free joints. The push-to-connect design minimizes errors and rework, enhancing overall installation efficiency compared to the flare fitting method.

Reliability and Leak Prevention

Push-to-connect fittings provide superior reliability and leak prevention due to their secure, tool-free installation with internal O-rings that maintain a tight seal under varying pressure conditions. Flare fittings rely on a metal-to-metal seal formed by a flared tube end and a compression nut, which can be susceptible to leaks if improperly tightened or damaged. The consistent sealing mechanism of push-to-connect fittings reduces the risk of human error and ensures long-lasting leak-free connections in plumbing and pneumatic systems.

Material Compatibility and Application Suitability

Push-to-connect fittings are typically made from corrosion-resistant materials such as brass, stainless steel, and plastic, ensuring compatibility with various liquids and gases in plumbing and pneumatic systems. Flare fittings, often made from brass or stainless steel, provide a durable, leak-resistant connection ideal for high-pressure applications like refrigeration and hydraulic systems. Your choice depends on the specific material compatibility and pressure requirements of your application to ensure reliable and safe connections.

Pressure and Temperature Ratings Comparison

Push-to-connect fittings typically handle pressure ratings up to 200 psi and temperatures ranging from -20degF to 200degF, making them ideal for low to moderate pressure applications. Flare fittings offer higher pressure capabilities, often exceeding 3000 psi, with temperature resistance up to 450degF, suitable for heavy-duty or high-temperature systems. Choosing your fitting depends on the specific pressure and temperature demands of your application to ensure safety and performance.

Cost Analysis: Initial and Long-Term Expenses

Push-to-connect fittings generally require a higher initial investment due to their advanced design and ease of installation, which saves labor costs. Flare fittings have lower upfront costs but may incur higher long-term expenses due to potential leaks and frequent maintenance. Your choice should consider both the immediate budget and the total cost of ownership over time to optimize efficiency and savings.

Maintenance and Durability Considerations

Push-to-connect fittings offer low maintenance due to their simple design that reduces leak points and are highly durable in applications with frequent assembly and disassembly. Flare fittings require regular inspection and occasional retightening to maintain a secure seal, as the metal-to-metal connection can degrade under vibration and thermal cycling. Both fittings provide strong durability, but push-to-connect fittings excel in ease of maintenance, while flare fittings are preferred in high-pressure hydraulic systems where long-term leak resistance is critical.

Common Industry Uses for Each Fitting Type

Push-to-connect fittings are widely used in pneumatic systems, HVAC applications, and compressed air lines due to their quick installation and reliable sealing without tools. Flare fittings are common in high-pressure fluid systems such as refrigeration, gas lines, and hydraulic applications, offering a durable metal-to-metal seal ideal for preventing leaks under demanding conditions. Your choice depends on the required pressure rating and ease of maintenance, with push-to-connect suited for frequent disconnections and flare fittings preferred for permanent, high-pressure connections.

Choosing the Right Fitting: Factors to Consider

When choosing between push-to-connect and flare fittings, consider installation speed, required tools, and leak resistance for your specific application. Push-to-connect fittings offer quick, tool-free assembly ideal for rapid repairs, while flare fittings provide robust, vibration-resistant seals suited for high-pressure systems. Your decision should prioritize compatibility with tubing materials, system pressure ratings, and ease of maintenance to ensure optimal performance and durability.

push-to-connect vs flare fitting Infographic

libmatt.com

libmatt.com