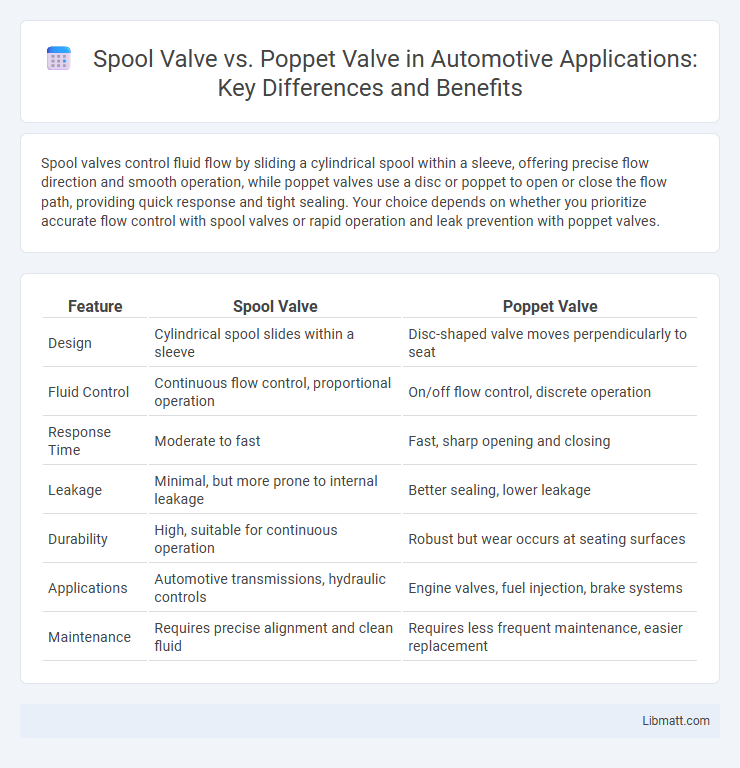

Spool valves control fluid flow by sliding a cylindrical spool within a sleeve, offering precise flow direction and smooth operation, while poppet valves use a disc or poppet to open or close the flow path, providing quick response and tight sealing. Your choice depends on whether you prioritize accurate flow control with spool valves or rapid operation and leak prevention with poppet valves.

Table of Comparison

| Feature | Spool Valve | Poppet Valve |

|---|---|---|

| Design | Cylindrical spool slides within a sleeve | Disc-shaped valve moves perpendicularly to seat |

| Fluid Control | Continuous flow control, proportional operation | On/off flow control, discrete operation |

| Response Time | Moderate to fast | Fast, sharp opening and closing |

| Leakage | Minimal, but more prone to internal leakage | Better sealing, lower leakage |

| Durability | High, suitable for continuous operation | Robust but wear occurs at seating surfaces |

| Applications | Automotive transmissions, hydraulic controls | Engine valves, fuel injection, brake systems |

| Maintenance | Requires precise alignment and clean fluid | Requires less frequent maintenance, easier replacement |

Introduction to Spool Valves and Poppet Valves

Spool valves control fluid flow through sliding cylindrical spools that open or close ports within a valve body, offering precise directional control in hydraulic and pneumatic systems. Poppet valves use a movable disc or plug to seal against a seat, providing rapid on/off flow control and excellent sealing under high-pressure conditions. Both valve types are essential in fluid power applications, with spool valves favored for complex flow paths and poppet valves preferred for reliable sealing and straightforward operation.

Basic Working Principles

Spool valves regulate fluid flow by sliding a cylindrical spool inside a bore to open or close defined flow paths, allowing precise control of hydraulic or pneumatic circuits. Poppet valves use a spring-loaded, disc-shaped element that seals against a seat when closed and lifts off to permit flow, offering rapid response and minimal leakage. Both valve types control flow direction and pressure, but spool valves excel in complex directional control, whereas poppet valves are favored for on/off functions and high-speed operations.

Key Structural Differences

Spool valves feature a cylindrical spool moving within a sleeve to control fluid flow, providing smooth, precise modulation and multiple flow paths. Poppet valves use a spring-loaded disk or cone that seals against a valve seat, offering rapid, positive shutoff with minimal leakage. The spool valve's sliding mechanism contrasts with the poppet valve's direct sealing action, influencing their suitability for different hydraulic and pneumatic applications.

Performance Characteristics

Spool valves provide smooth and precise control of fluid flow with minimal pressure drop, making them ideal for applications requiring gradual modulation. Poppet valves offer faster response times and higher flow rates due to their quick opening and closing action, which enhances performance in dynamic systems. Your choice between spool and poppet valves depends on whether you prioritize accuracy and control or speed and flow capacity in your hydraulic system.

Flow Control Capabilities

Spool valves provide precise flow control by sliding a cylindrical spool within a bore to regulate fluid passage, allowing smooth modulation and variable flow rates. Poppet valves, on the other hand, offer quick on/off flow control with minimal leakage, ideal for high-pressure systems but less effective for fine flow adjustments. For your application requiring nuanced control over fluid flow, spool valves typically offer better capabilities due to their versatile positioning options.

Applications and Industry Usage

Spool valves dominate hydraulic systems in construction equipment and industrial machinery due to their precise flow control and ability to handle high-pressure applications. Poppet valves are preferred in automotive engines, pneumatic tools, and fluid control systems where quick response and leak-tight sealing are critical. Both valves serve essential roles across sectors like aerospace, manufacturing, and agriculture, with spool valves favored for complex directional control and poppet valves excelling in on/off flow regulation.

Advantages of Spool Valves

Spool valves offer superior flow control and faster response times compared to poppet valves, making them ideal for precise hydraulic and pneumatic applications. Their simple design reduces wear and maintenance, enhancing durability and reliability in high-cycle operations. You benefit from smoother operation and better compatibility with automated systems due to their ability to modulate flow continuously.

Advantages of Poppet Valves

Poppet valves offer superior sealing capabilities due to their direct seating design, minimizing leakage and improving efficiency in hydraulic systems. Their simple structure allows for quick response times and reliable operation under high pressure and temperature conditions. You benefit from enhanced durability and low maintenance requirements, making poppet valves ideal for applications demanding precise flow control and longevity.

Limitations and Drawbacks

Spool valves often suffer from internal leakage and limited pressure ratings, reducing overall hydraulic efficiency and system reliability. Poppet valves face issues with slower response times and higher wear rates due to their seating and sealing mechanisms, impacting durability in high-cycle applications. Understanding these limitations helps optimize your valve selection for specific performance requirements and operational conditions.

Choosing the Right Valve for Your System

Selecting the right valve for your hydraulic or pneumatic system depends on factors such as flow control accuracy, response time, and durability. Spool valves offer precise control and smooth modulation suitable for complex directional control, while poppet valves provide rapid response and superior sealing for high-pressure applications. Understanding operational requirements and fluid characteristics ensures optimal performance and system longevity by choosing between spool and poppet valve designs.

spool valve vs poppet valve Infographic

libmatt.com

libmatt.com