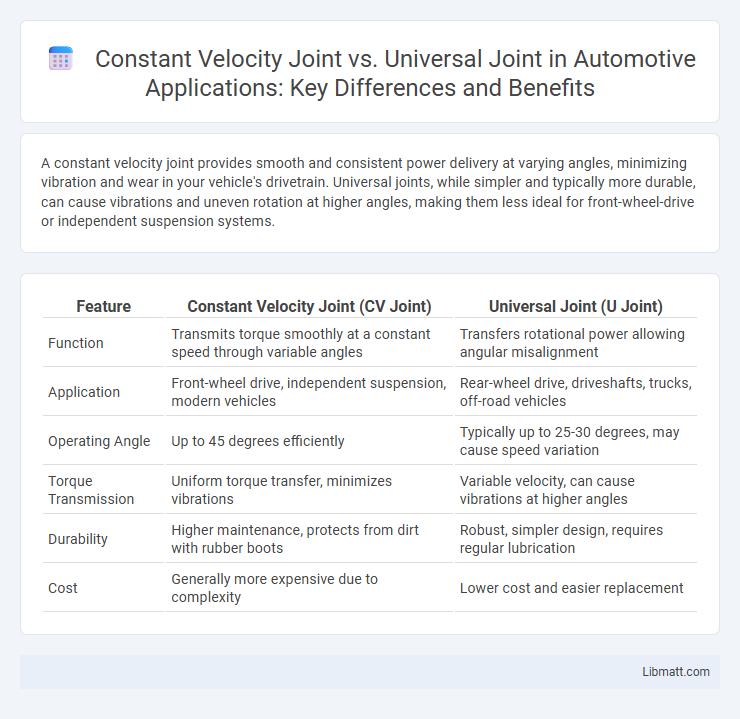

A constant velocity joint provides smooth and consistent power delivery at varying angles, minimizing vibration and wear in your vehicle's drivetrain. Universal joints, while simpler and typically more durable, can cause vibrations and uneven rotation at higher angles, making them less ideal for front-wheel-drive or independent suspension systems.

Table of Comparison

| Feature | Constant Velocity Joint (CV Joint) | Universal Joint (U Joint) |

|---|---|---|

| Function | Transmits torque smoothly at a constant speed through variable angles | Transfers rotational power allowing angular misalignment |

| Application | Front-wheel drive, independent suspension, modern vehicles | Rear-wheel drive, driveshafts, trucks, off-road vehicles |

| Operating Angle | Up to 45 degrees efficiently | Typically up to 25-30 degrees, may cause speed variation |

| Torque Transmission | Uniform torque transfer, minimizes vibrations | Variable velocity, can cause vibrations at higher angles |

| Durability | Higher maintenance, protects from dirt with rubber boots | Robust, simpler design, requires regular lubrication |

| Cost | Generally more expensive due to complexity | Lower cost and easier replacement |

Introduction to Constant Velocity Joints and Universal Joints

Constant Velocity (CV) joints are specialized automotive components designed to transmit consistent rotational force at varying angles, crucial for front-wheel drive vehicles and independent suspension systems. Universal joints (U-joints) allow for flexible connection between shafts at different angles but can cause speed fluctuations and wear under high angles or speeds. Your choice between CV joints and U-joints influences vehicle performance, durability, and smoothness in power transmission.

Fundamental Working Principles

Constant Velocity (CV) joints use a system of ball bearings inside a cage to maintain a constant rotational speed regardless of the angle, enabling smooth power transmission in front-wheel-drive vehicles and independent suspensions. Universal Joints (U-joints) rely on a cross-shaped yoke and bearing system that allows rotation at varying angles but causes speed fluctuations during operation, commonly found in rear-wheel-drive drivetrains. CV joints provide consistent torque transfer and reduce vibration, while U-joints offer simpler mechanics but introduce angular velocity variations as the drive shaft rotates.

Design Differences

Constant Velocity (CV) joints feature an enclosed, ball-bearing design that maintains uniform rotational speed regardless of angles, while Universal Joints (U-joints) use a cross-shaped pivot mechanism allowing rotation but causing velocity fluctuations at varying angles. CV joints are encased to protect against dirt and debris, enhancing durability and smooth power delivery, whereas U-joints are more exposed and typically found in simpler, less angle-sensitive applications. Your choice between the two depends on the required smoothness and angle flexibility in the drivetrain design.

Types and Variations

Constant velocity (CV) joints primarily include ball-type joints such as Rzeppa and tripod designs, which offer smooth power transfer at varying angles, while universal (U) joints feature cross-shaped spider components allowing for angular misalignment but with velocity fluctuations. CV joints are commonly used in front-wheel-drive vehicles due to their ability to maintain constant rotational speed, whereas U-joints are typical in rear-wheel-drive and off-road applications where higher torque tolerance is needed. Understanding these types and variations helps you select the appropriate joint for your vehicle's drivetrain requirements and performance needs.

Efficiency and Performance Comparison

Constant Velocity (CV) joints provide superior efficiency and smoother power delivery compared to Universal Joints (U-joints) due to their ability to maintain a constant rotational speed without fluctuations. CV joints excel in high-speed applications and sharp-angle turns, reducing vibration and drivetrain wear, enhancing overall vehicle performance. Your choice between these joints will impact drivetrain smoothness and reliability, with CV joints generally outperforming U-joints in precision and longevity.

Applications in Automotive and Industrial Sectors

Constant Velocity (CV) joints are primarily used in front-wheel-drive vehicles for smooth power transmission at varying angles, while Universal Joints (U-joints) are common in rear-wheel-drive and heavy-duty industrial machinery for handling higher torque with angular misalignment. CV joints excel in automotive applications requiring precision and minimal vibration, such as in car axles and drivetrain systems, whereas U-joints are favored in agricultural equipment, forklifts, and industrial conveyors due to their robustness and ability to accommodate larger angular variations. Your choice between CV and U-joints depends on specific application demands, including torque capacity, angular range, and maintenance requirements.

Durability and Maintenance Requirements

Constant velocity (CV) joints offer superior durability compared to universal joints (U-joints) due to their ability to maintain consistent rotational speed without increasing wear under variable angles. CV joints require less frequent maintenance, primarily needing protection from contaminants through intact rubber boots that prevent grease leakage. Your choice between these joints should consider the long-term maintenance demands and reliability under dynamic driving conditions, with CV joints generally providing a more robust solution for modern vehicles.

Pros and Cons of Constant Velocity Joints

Constant velocity (CV) joints provide smooth power transfer at a consistent rotational speed regardless of the angle, reducing drivetrain vibration and enhancing vehicle handling. They excel in front-wheel drive and all-wheel drive vehicles where steering angles vary, but their complexity and higher manufacturing cost compared to universal joints can lead to more expensive repairs. CV joints also require regular maintenance and gaiter inspection to prevent contamination and premature wear, making them less durable in harsh environments than universal joints.

Pros and Cons of Universal Joints

Universal joints offer the advantage of simplicity and cost-effectiveness, making them suitable for a wide range of applications with moderate angular movement. However, they can cause vibration and wear at higher angles due to inconsistent velocity, leading to potential maintenance issues. Your choice between universal and constant velocity joints depends on the need for smooth power transmission and durability at varying shaft angles.

Choosing the Right Joint for Your Application

When selecting between a Constant Velocity (CV) joint and a Universal Joint (U-joint), consider the application's speed, angle, and vibration requirements. CV joints deliver smoother rotation at varying angles with less vibration, making them ideal for front-wheel-drive vehicles and precision machinery, while U-joints excel in simpler, lower-speed applications with larger operating angles. Understanding your equipment's load, operating environment, and desired durability will help you choose the right joint that ensures optimal performance and longevity.

Constant Velocity Joint vs Universal Joint Infographic

libmatt.com

libmatt.com