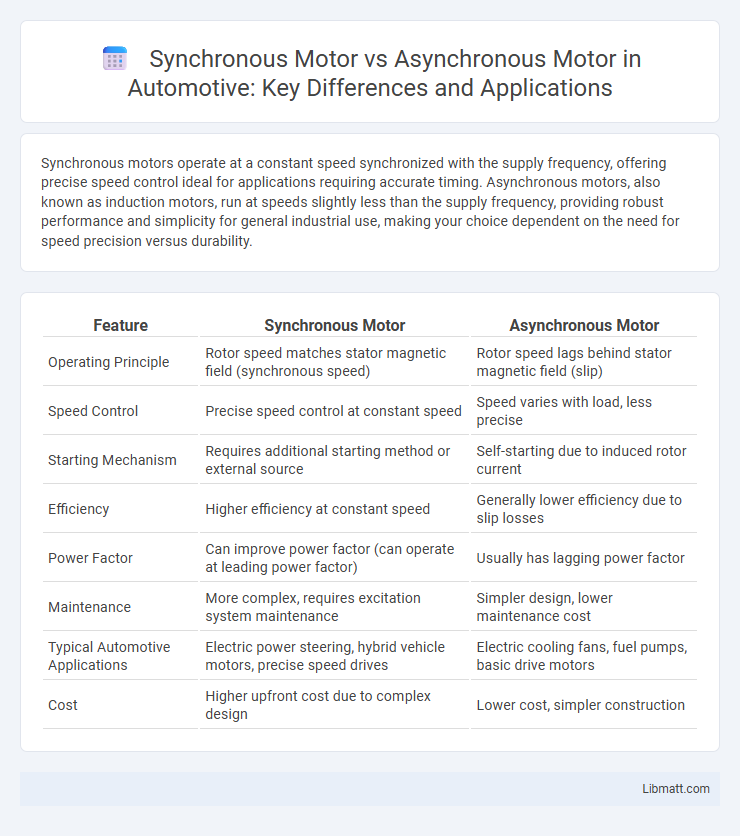

Synchronous motors operate at a constant speed synchronized with the supply frequency, offering precise speed control ideal for applications requiring accurate timing. Asynchronous motors, also known as induction motors, run at speeds slightly less than the supply frequency, providing robust performance and simplicity for general industrial use, making your choice dependent on the need for speed precision versus durability.

Table of Comparison

| Feature | Synchronous Motor | Asynchronous Motor |

|---|---|---|

| Operating Principle | Rotor speed matches stator magnetic field (synchronous speed) | Rotor speed lags behind stator magnetic field (slip) |

| Speed Control | Precise speed control at constant speed | Speed varies with load, less precise |

| Starting Mechanism | Requires additional starting method or external source | Self-starting due to induced rotor current |

| Efficiency | Higher efficiency at constant speed | Generally lower efficiency due to slip losses |

| Power Factor | Can improve power factor (can operate at leading power factor) | Usually has lagging power factor |

| Maintenance | More complex, requires excitation system maintenance | Simpler design, lower maintenance cost |

| Typical Automotive Applications | Electric power steering, hybrid vehicle motors, precise speed drives | Electric cooling fans, fuel pumps, basic drive motors |

| Cost | Higher upfront cost due to complex design | Lower cost, simpler construction |

Introduction to Synchronous and Asynchronous Motors

Synchronous motors operate at a constant speed, synchronized with the supply frequency, making them ideal for applications requiring precise speed control and power factor correction. Asynchronous motors, also known as induction motors, run at speeds slightly less than the supply frequency and are widely used due to their rugged construction, simplicity, and cost-effectiveness. Understanding the differences between synchronous and asynchronous motors helps optimize your choice for specific industrial and commercial uses.

Basic Working Principles

A synchronous motor operates by locking its rotor speed to the frequency of the supply current, maintaining a constant speed regardless of load variations. An asynchronous motor, also called an induction motor, functions by inducing current in the rotor through electromagnetic induction, resulting in rotor speed slightly less than the synchronous speed. Your choice depends on the requirement for precise speed control or simple, robust operation in various applications.

Construction Differences

Synchronous motors feature a rotor with permanent magnets or DC-excited windings that rotate at a fixed speed synchronized with the stator's rotating magnetic field, while asynchronous motors (induction motors) have a rotor made of laminated iron cores with squirrel-cage conductors or wound rotors, relying on induction to produce torque. The stator of both motors contains three-phase windings but the asynchronous motor's rotor speed lags behind the stator field, creating slip essential for torque generation. Construction differences also affect complexity and cost, with synchronous motors requiring additional components like slip rings or permanent magnets, unlike the simpler squirrel-cage rotor of asynchronous motors.

Speed and Performance Characteristics

Synchronous motors operate at a constant speed synchronized with the supply frequency, providing precise speed control essential for applications requiring exact timing. Asynchronous motors, also known as induction motors, run at speeds slightly less than the synchronous speed, with slip varying based on load conditions, resulting in less precise speed control but simpler construction. Performance-wise, synchronous motors offer higher efficiency and power factor correction, while asynchronous motors are rugged, cost-effective, and suitable for variable load operations.

Efficiency Comparison

Synchronous motors typically offer higher efficiency than asynchronous motors due to their constant speed operation and reduced slip losses. The absence of rotor current in synchronous motors minimizes energy dissipation, making them ideal for applications demanding precise speed control and energy savings. Your choice between these motors should consider efficiency requirements alongside operational conditions to optimize performance and reduce energy costs.

Starting and Control Methods

Synchronous motors require external starting methods like pony motors or variable frequency drives (VFDs) due to their inability to start on load, making precise control of speed and position achievable through direct synchronization with the supply frequency. Asynchronous motors, or induction motors, start directly on the supply and naturally reach a speed slightly less than synchronous speed, with control typically managed by adjusting voltage, frequency, or using slip control techniques. Your choice depends on the application's need for speed accuracy and complexity of the starting system.

Applications in Industry

Synchronous motors are widely used in industries requiring precise speed control and constant speed under varying loads, such as in conveyor systems, robotics, and synchronous clocks. Asynchronous motors, also known as induction motors, are preferred for applications demanding high starting torque and robustness, including pumps, fans, and compressors. Both motor types play critical roles in manufacturing and automation, with synchronous motors offering efficiency in power factor correction and asynchronous motors excelling in cost-effective, reliable operation.

Advantages and Disadvantages

Synchronous motors offer precise speed control and constant speed operation, making them ideal for applications requiring accurate timing, while their high initial cost and complex construction can be drawbacks. Asynchronous motors, or induction motors, are known for their ruggedness, low cost, and simple design, but they suffer from slip and variable speed under load, limiting their precision. The choice between synchronous and asynchronous motors depends on application requirements such as speed accuracy, efficiency, and maintenance considerations.

Maintenance and Operational Costs

Synchronous motors typically require higher initial investment and more precise maintenance due to their complex rotor construction and excitation system, leading to increased operational costs. Asynchronous motors, or induction motors, are generally more robust with simpler design, resulting in lower maintenance requirements and reduced downtime expenses. Your choice between the two should consider long-term maintenance budgets and the specific operational demands of your application.

Selection Criteria for Industrial Use

Synchronous motors provide precise speed control and high efficiency, making them ideal for applications requiring constant speed and power factor correction. Asynchronous motors, commonly used in industry, offer robust construction, lower initial cost, and simpler maintenance, suitable for variable loads and less critical speed requirements. Your selection should balance factors such as load consistency, energy efficiency, startup torque, and operational costs to optimize industrial performance.

Synchronous motor vs Asynchronous motor Infographic

libmatt.com

libmatt.com