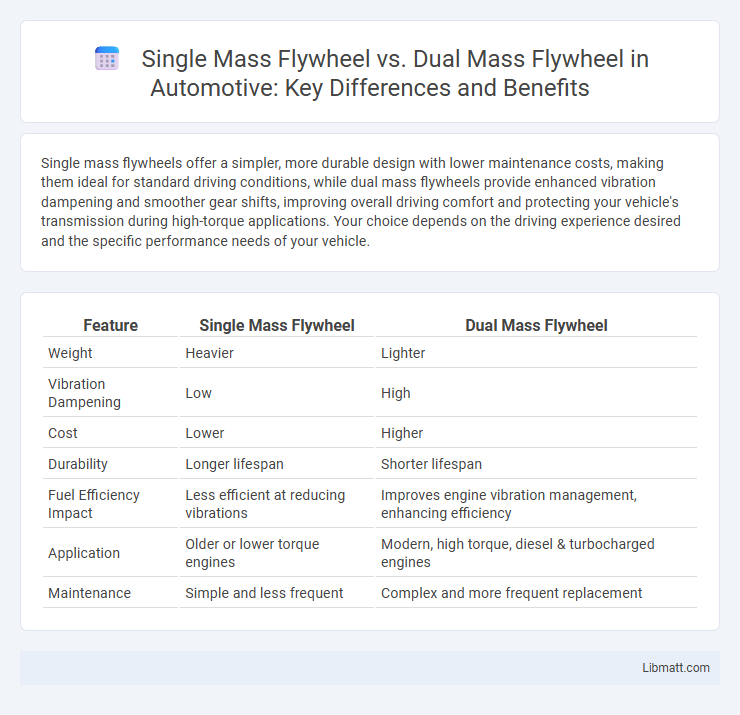

Single mass flywheels offer a simpler, more durable design with lower maintenance costs, making them ideal for standard driving conditions, while dual mass flywheels provide enhanced vibration dampening and smoother gear shifts, improving overall driving comfort and protecting your vehicle's transmission during high-torque applications. Your choice depends on the driving experience desired and the specific performance needs of your vehicle.

Table of Comparison

| Feature | Single Mass Flywheel | Dual Mass Flywheel |

|---|---|---|

| Weight | Heavier | Lighter |

| Vibration Dampening | Low | High |

| Cost | Lower | Higher |

| Durability | Longer lifespan | Shorter lifespan |

| Fuel Efficiency Impact | Less efficient at reducing vibrations | Improves engine vibration management, enhancing efficiency |

| Application | Older or lower torque engines | Modern, high torque, diesel & turbocharged engines |

| Maintenance | Simple and less frequent | Complex and more frequent replacement |

Introduction to Flywheels in Automotive Systems

Flywheels in automotive systems store rotational energy to smooth engine power delivery and improve drivability. Single mass flywheels consist of a solid, single-piece construction offering durability and simplicity, best suited for engines with lower torque and less vibration. Dual mass flywheels incorporate two separate masses connected by springs, designed to absorb engine vibrations and reduce drivetrain noise in higher torque engines and modern vehicles.

What is a Single Mass Flywheel?

A Single Mass Flywheel is a solid, one-piece component made typically from cast iron or steel that connects the engine to the transmission, providing rotational inertia to smooth engine operation. It offers durability and simplicity, making it suitable for lower torque engines and reducing complexity in drivetrain design. Single Mass Flywheels are generally lighter and less expensive compared to Dual Mass Flywheels but can transmit more vibration and noise to the cabin.

What is a Dual Mass Flywheel?

A Dual Mass Flywheel (DMF) is an advanced automotive component designed to reduce engine vibrations and improve driving comfort by utilizing two separate flywheels connected by a set of springs. It absorbs torsional vibrations more effectively than a Single Mass Flywheel (SMF), enhancing drivetrain smoothness and protecting transmission components from wear. DMFs are commonly used in modern vehicles with turbocharged or high-torque engines to enhance fuel efficiency and reduce noise.

Key Differences Between Single and Dual Mass Flywheels

Single mass flywheels are made from a solid piece of metal, offering durability and simplicity in design, making them ideal for vehicles with lower torque engines. Dual mass flywheels consist of two connected flywheels separated by a damping mechanism, which reduces vibrations and improves driving comfort in high-torque, modern engines. Your choice between single mass and dual mass flywheels impacts vehicle performance, noise levels, and maintenance requirements, with dual mass providing smoother operation but often higher replacement costs.

Performance Comparison: Efficiency and Response

Single mass flywheels offer higher efficiency and quicker engine response due to their simpler construction and lower rotational inertia, making them ideal for performance-focused vehicles. Dual mass flywheels enhance driving smoothness by effectively damping engine vibrations, but this increased complexity can slightly reduce efficiency and delay throttle response. Your choice between the two depends on whether you prioritize direct engine feedback and efficiency or improved ride comfort and vibration isolation.

Vibration and Noise Reduction: Which Flywheel Wins?

Dual mass flywheels excel in vibration and noise reduction by absorbing engine torque fluctuations through their two-layer design, significantly smoothing driveline oscillations and reducing NVH (noise, vibration, and harshness) in modern vehicles. Single mass flywheels, while simpler and more durable, transmit more engine vibrations directly to the drivetrain, resulting in higher noise levels and less refined driving comfort. For enhanced vibration dampening and quieter operation, dual mass flywheels provide superior performance compared to single mass flywheels.

Durability and Maintenance Considerations

Single mass flywheels offer higher durability due to their simpler design and fewer moving parts, resulting in lower maintenance requirements over time. Dual mass flywheels, while providing superior vibration damping, tend to wear out faster because of their complex construction, necessitating more frequent inspections and potential replacements. Choosing between the two depends on balancing long-term maintenance costs against the driving comfort benefits provided by the dual mass flywheel.

Cost Analysis: Initial Investment and Long-Term Value

Single mass flywheels offer a lower initial investment compared to dual mass flywheels due to simpler design and manufacturing processes. However, dual mass flywheels provide better vibration damping and reduce drivetrain wear, potentially lowering long-term maintenance costs and enhancing vehicle longevity. Your choice depends on balancing upfront savings against possible increased expenses from frequent repairs with single mass flywheels.

Application Suitability: Which Flywheel for Which Vehicle?

Single mass flywheels are ideal for lighter vehicles with less powerful engines, offering durability and straightforward maintenance. Dual mass flywheels excel in heavier, high-torque engines by reducing vibrations and improving driving comfort. Your vehicle's engine size and driving conditions determine the optimal flywheel choice for performance and longevity.

Conclusion: Making the Right Choice

Choosing between a single mass flywheel (SMF) and a dual mass flywheel (DMF) depends on vehicle type, driving conditions, and desired performance. SMFs offer durability and simplicity, ideal for high-performance or older vehicles, while DMFs provide smoother operation and vibration dampening, suitable for modern cars with complex drivetrains. Evaluating factors like maintenance cost, noise level, and driving style will guide the optimal flywheel selection for longevity and efficiency.

Single mass flywheel vs Dual mass flywheel Infographic

libmatt.com

libmatt.com