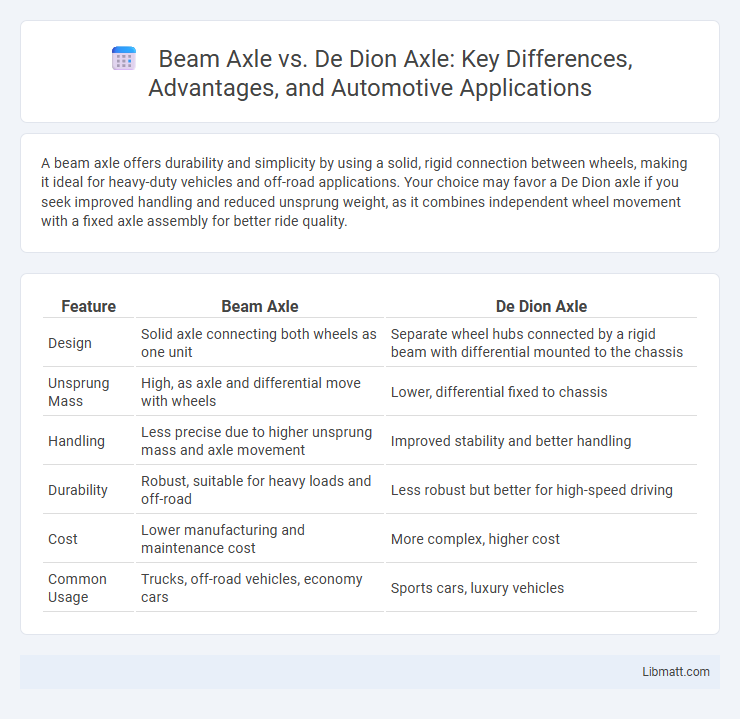

A beam axle offers durability and simplicity by using a solid, rigid connection between wheels, making it ideal for heavy-duty vehicles and off-road applications. Your choice may favor a De Dion axle if you seek improved handling and reduced unsprung weight, as it combines independent wheel movement with a fixed axle assembly for better ride quality.

Table of Comparison

| Feature | Beam Axle | De Dion Axle |

|---|---|---|

| Design | Solid axle connecting both wheels as one unit | Separate wheel hubs connected by a rigid beam with differential mounted to the chassis |

| Unsprung Mass | High, as axle and differential move with wheels | Lower, differential fixed to chassis |

| Handling | Less precise due to higher unsprung mass and axle movement | Improved stability and better handling |

| Durability | Robust, suitable for heavy loads and off-road | Less robust but better for high-speed driving |

| Cost | Lower manufacturing and maintenance cost | More complex, higher cost |

| Common Usage | Trucks, off-road vehicles, economy cars | Sports cars, luxury vehicles |

Introduction to Solid Axles

Solid axles, including beam axles and De Dion axles, serve as fundamental suspension components that connect wheels on the same axle line. Beam axles are rigid and combine the wheels and differential into a single solid assembly, providing durability and simplicity ideal for heavy-duty applications. Your choice between these axles impacts ride quality and handling, with De Dion axles offering improved wheel alignment and reduced unsprung weight for better performance.

What is a Beam Axle?

A beam axle is a solid, rigid axle connecting the wheels on opposite sides of a vehicle, ensuring they move together as a single unit. It is commonly used in heavy-duty trucks and off-road vehicles due to its durability and simple design, providing high strength and load-bearing capacity. The beam axle's construction limits independent wheel movement, which can affect ride quality and handling compared to more advanced suspension types.

What is a De Dion Axle?

A De Dion axle is a type of rear suspension system that separates the location and alignment of the wheels from the differential, enhancing handling and reducing unsprung weight compared to a traditional beam axle. It uses a rigid tubular beam connecting the wheels with the differential mounted separately on the chassis, allowing for improved ride quality and better wheel camber control. This design offers a balance between the simplicity of a live axle and the performance benefits of independent suspension.

Key Design Differences

Beam axles feature a solid, rigid design connecting both wheels, ensuring consistent camber and alignment but limiting independent suspension movement. De Dion axles separate the wheel hubs from the differential, reducing unsprung weight and allowing improved ride quality and handling. The fundamental distinction lies in the beam axle's integration of wheel and differential as one unit versus the De Dion's distinct separation to enhance performance.

Performance Comparison

Beam axles offer robust durability and simple design, excelling in heavy-duty applications with consistent wheel alignment under load, yet they sacrifice ride comfort and independent wheel movement. De Dion axles provide improved handling and ride quality by allowing independent wheel camber adjustment and reducing unsprung weight, leading to better traction and stability on uneven surfaces. Performance-wise, De Dion axles outperform beam axles in dynamic driving conditions while beam axles remain superior for load-bearing resilience and cost-effectiveness.

Ride Comfort and Handling

Beam axles offer a simpler, more robust design but often compromise ride comfort due to their rigid connection between wheels, leading to more vibration and less precise handling on uneven surfaces. De Dion axles improve ride quality by allowing each wheel to move independently, reducing unsprung weight and enhancing traction, which results in better handling and smoother comfort. This design balances the solidity of a beam axle with improved suspension dynamics, making it favorable for performance-oriented and off-road applications.

Weight and Complexity

The Beam Axle design is heavier due to its solid construction connecting both wheels, leading to increased unsprung mass and simpler mechanical complexity. In contrast, the De Dion Axle reduces unsprung weight by separating the differential from the axle, offering lighter overall weight but with increased mechanical complexity and more components. This difference impacts vehicle handling, suspension performance, and maintenance requirements.

Maintenance Requirements

Beam axles require regular lubrication of the central pivot and suspension joints to prevent wear and ensure proper alignment, often resulting in higher maintenance due to increased unsprung weight. De Dion axles feature separated wheel hubs with a rigid connecting tube, reducing unsprung weight and easing wheel alignment, which lowers overall maintenance frequency. The simpler construction of beam axles compared to the more complex De Dion setup can lead to more frequent inspections and repairs, especially in off-road or heavy-duty applications.

Typical Applications and Use Cases

Beam axles are commonly used in heavy-duty trucks, off-road vehicles, and trailers due to their durability, simplicity, and load-carrying capacity, making them ideal for rugged terrain and heavy loads. De Dion axles are favored in high-performance and sports cars where independent wheel movement improves handling and ride comfort while maintaining better camber control than traditional beam axles. Your choice depends on whether you prioritize robustness and cost-effectiveness with beam axles or enhanced handling and reduced unsprung weight with De Dion axles.

Which Axle is Best for Your Needs?

Choosing between a beam axle and a De Dion axle depends on your vehicle's intended use and performance priorities. Beam axles are sturdy and cost-effective, ideal for off-road and heavy-duty applications due to their durability and simple design. De Dion axles provide better handling and ride comfort by minimizing unsprung weight, making them suitable for performance-oriented vehicles that require improved cornering and stability.

Beam Axle vs De Dion Axle Infographic

libmatt.com

libmatt.com