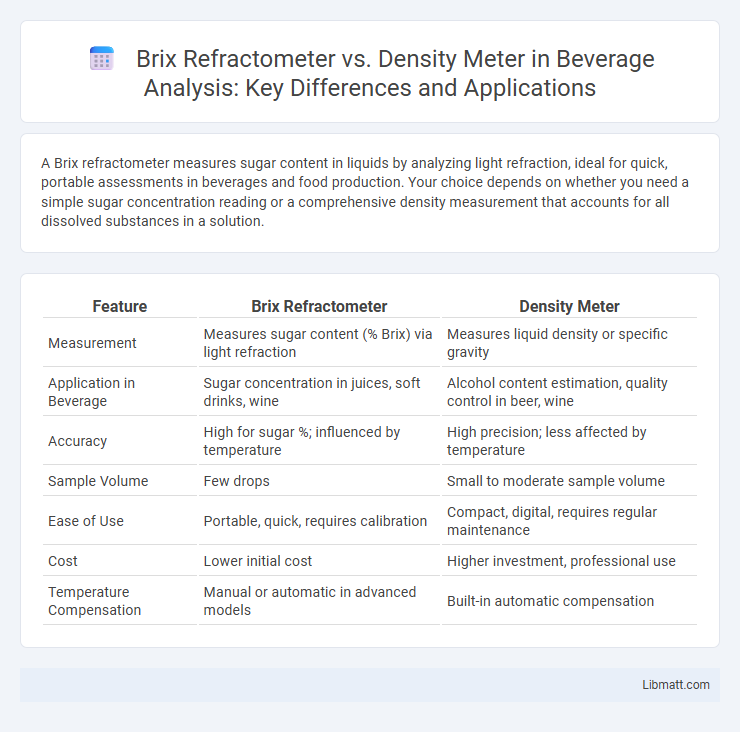

A Brix refractometer measures sugar content in liquids by analyzing light refraction, ideal for quick, portable assessments in beverages and food production. Your choice depends on whether you need a simple sugar concentration reading or a comprehensive density measurement that accounts for all dissolved substances in a solution.

Table of Comparison

| Feature | Brix Refractometer | Density Meter |

|---|---|---|

| Measurement | Measures sugar content (% Brix) via light refraction | Measures liquid density or specific gravity |

| Application in Beverage | Sugar concentration in juices, soft drinks, wine | Alcohol content estimation, quality control in beer, wine |

| Accuracy | High for sugar %; influenced by temperature | High precision; less affected by temperature |

| Sample Volume | Few drops | Small to moderate sample volume |

| Ease of Use | Portable, quick, requires calibration | Compact, digital, requires regular maintenance |

| Cost | Lower initial cost | Higher investment, professional use |

| Temperature Compensation | Manual or automatic in advanced models | Built-in automatic compensation |

Introduction to Sugar Content Measurement

Brix refractometers measure sugar content by determining the refractive index of a liquid, providing rapid and accurate results primarily used in the food and beverage industry. Density meters assess sugar concentration through liquid density, offering precise measurements essential for quality control in sugar production and fermentation processes. Both instruments are critical for monitoring sugar levels, but Brix refractometers are favored for their ease of use and speed in field applications.

What is a Brix Refractometer?

A Brix refractometer measures the sugar content in liquids by analyzing the degree to which light bends, or refracts, through the sample, providing results in Brix units representing the percentage of sucrose by weight. This precise tool is widely used in food and beverage industries to assess sweetness levels, quality, and ripeness of fruits. Unlike a density meter that measures mass per unit volume, the Brix refractometer specifically quantifies soluble solids, making Your evaluations more focused on sugar concentration.

How Does a Density Meter Work?

A density meter measures the mass per unit volume of a liquid by using techniques such as vibrating tube, oscillation frequency, or differential pressure sensors to determine fluid density accurately. The instrument calculates density by assessing the response of a vibrating element immersed in the sample or measuring the force exerted by the fluid, providing precise data essential for quality control in industries like food, pharmaceuticals, and chemicals. Unlike a Brix refractometer, which estimates sugar content via light refraction, the density meter offers direct, quantitative density readings critical for process monitoring and formulation adjustments.

Key Differences Between Brix Refractometers and Density Meters

Brix refractometers measure the sugar content of liquids by analyzing light refraction, providing rapid and non-destructive results primarily for solutions such as fruit juices, wine, and honey. Density meters, alternatively, determine the mass per unit volume of a liquid, offering versatile applications in quality control across industries including petrochemical, pharmaceutical, and food processing. The main difference lies in their measurement focus--Brix refractometers quantify soluble solids concentration, while density meters deliver precise density values, impacting their suitability depending on the analytical need.

Accuracy and Precision Comparison

Brix refractometers provide highly accurate measurements of sugar concentration by analyzing light refraction, ideal for industries requiring precise monitoring of sweetness. Density meters offer precise readings of liquid density, which correlates with concentration but can be influenced by temperature and sample composition. Your choice should consider that refractometers generally deliver faster and more straightforward accuracy for sugar metrics, while density meters excel in comprehensive compositional analysis.

Application Areas: Brix Refractometers vs Density Meters

Brix refractometers are predominantly used in the food and beverage industry to measure sugar concentration in liquids such as fruit juices, wine, and soft drinks, providing quick and accurate assessments of sweetness levels. Density meters find broad application in chemical processing, petroleum, and pharmaceuticals, where precise determination of fluid density is critical for quality control, formulation, and product consistency. Both instruments serve essential roles in quality assurance but are selected based on the specific property measurement--sugar content versus fluid density--required by the industry.

Ease of Use and Maintenance

Brix refractometers are typically easier to use and maintain due to their simple handheld design, requiring minimal calibration and quick sample application. Density meters often involve more complex setups, regular calibration with calibration standards, and routine cleaning to ensure precise measurements. Your choice depends on whether you prioritize quick, low-maintenance operation (Brix refractometer) or detailed density analysis requiring more upkeep (density meter).

Cost and Accessibility

Brix refractometers are generally more affordable and portable, making them accessible for quick sugar content measurements in labs and field settings. Density meters, while offering precise density and specific gravity readings, tend to be more expensive and require specialized maintenance and calibration. Your choice depends on budget constraints and the need for mobility versus detailed density analysis.

Advantages and Limitations of Both Instruments

Brix refractometers offer rapid, non-destructive sugar content measurement with minimal sample volume, making them ideal for field and laboratory use, though their accuracy can be affected by temperature and the presence of dissolved solids other than sugars. Density meters provide precise, temperature-compensated density readings crucial for quality control in industries such as brewing and food processing, but they require larger sample volumes and are generally more expensive and less portable. Both instruments complement each other by balancing ease of use and measurement specificity, with refractometers favored for quick screening and density meters preferred for detailed compositional analysis.

Choosing the Right Tool for Your Needs

Brix refractometers measure sugar content in liquids by analyzing light refraction, ideal for the food and beverage industry to ensure product consistency. Density meters provide precise mass-to-volume ratios, suitable for applications requiring accurate density measurements like petrochemical or pharmaceutical sectors. Selecting between these tools depends on the specific parameter needed--opt for a refractometer for quick sugar content estimation and a density meter for comprehensive density analysis.

Brix refractometer vs density meter Infographic

libmatt.com

libmatt.com