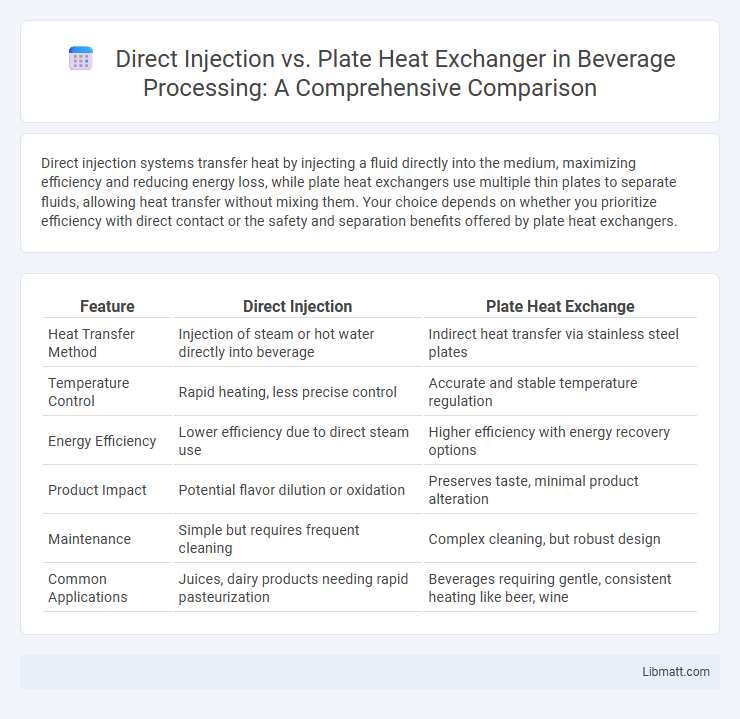

Direct injection systems transfer heat by injecting a fluid directly into the medium, maximizing efficiency and reducing energy loss, while plate heat exchangers use multiple thin plates to separate fluids, allowing heat transfer without mixing them. Your choice depends on whether you prioritize efficiency with direct contact or the safety and separation benefits offered by plate heat exchangers.

Table of Comparison

| Feature | Direct Injection | Plate Heat Exchange |

|---|---|---|

| Heat Transfer Method | Injection of steam or hot water directly into beverage | Indirect heat transfer via stainless steel plates |

| Temperature Control | Rapid heating, less precise control | Accurate and stable temperature regulation |

| Energy Efficiency | Lower efficiency due to direct steam use | Higher efficiency with energy recovery options |

| Product Impact | Potential flavor dilution or oxidation | Preserves taste, minimal product alteration |

| Maintenance | Simple but requires frequent cleaning | Complex cleaning, but robust design |

| Common Applications | Juices, dairy products needing rapid pasteurization | Beverages requiring gentle, consistent heating like beer, wine |

Introduction to Direct Injection and Plate Heat Exchange

Direct injection delivers heat by injecting steam directly into the fluid, ensuring rapid temperature increase and high energy efficiency. Plate heat exchangers transfer heat between two separate fluids via metal plates, offering effective thermal exchange without mixing the fluids. Understanding these methods helps you select the optimal system based on your process requirements and thermal efficiency goals.

How Direct Injection Works

Direct injection works by introducing hot water directly into your heating system's heat exchanger, where it transfers heat efficiently without mixing fluids. This method enhances energy transfer by minimizing heat loss through direct contact between the heat source and the system. Compared to plate heat exchange, direct injection offers a simpler design and quicker response time for temperature changes in your heating setup.

How Plate Heat Exchange Operates

Plate heat exchangers operate by passing two fluids through alternating, thin metal plates, allowing heat transfer without direct contact between the fluids. The design maximizes surface area and turbulence, enhancing thermal efficiency while minimizing energy loss. This method enables effective heat exchange in compact spaces, widely used in HVAC, refrigeration, and industrial processes.

Key Differences Between Direct Injection and Plate Heat Exchange

Direct injection delivers heated liquids by injecting them directly into the target fluid, ensuring rapid temperature change and minimal heat loss. Plate heat exchangers transfer heat through metal plates separating the fluids, allowing efficient heat exchange without direct mixing. Your choice depends on system requirements for temperature control, contamination risk, and maintenance complexity.

Efficiency Comparison: Direct Injection vs Plate Heat Exchange

Direct injection systems typically offer higher thermal efficiency by minimizing heat loss during the transfer process, resulting in faster heating and reduced energy consumption. Plate heat exchangers provide reliable efficiency through large surface areas for heat transfer and counterflow design, ensuring stable temperature control with minimal fluid mixing. Your choice between the two depends on specific application needs, with direct injection excelling in energy savings and plate heat exchangers delivering consistent performance in various industrial heating tasks.

Energy Consumption Analysis

Direct injection systems typically consume less energy by transferring heat directly, minimizing thermal losses compared to plate heat exchangers that rely on indirect heat transfer through metal plates. Your energy consumption is often reduced with direct injection because it eliminates intermediate heat transfer fluids, improving overall system efficiency. However, plate heat exchangers may be favored for applications requiring precise temperature control despite slightly higher energy usage.

Applications and Industry Use Cases

Direct injection heat exchangers are widely used in industries requiring rapid temperature changes and minimal mixing, such as chemical processing, food and beverage production, and pharmaceutical manufacturing. Plate heat exchangers excel in HVAC systems, refrigeration, and power plants due to their high efficiency, compact design, and ease of maintenance. Your choice between these technologies depends on the specific application requirements, including fluid compatibility, temperature control precision, and space constraints.

Maintenance and Operational Considerations

Direct injection systems require less frequent maintenance as they have fewer mechanical components but may demand regular monitoring to avoid contamination or clogging. Plate heat exchangers involve routine cleaning to prevent fouling and ensure efficient heat transfer, with gasket replacement being a critical maintenance task. Your choice depends on balancing the ease of operation and the time investment for upkeep in your specific application.

Cost Implications and ROI

Direct injection systems generally offer lower upfront costs compared to plate heat exchangers due to simpler design and fewer components. Plate heat exchangers, while more expensive initially, provide higher energy efficiency and reduced operating costs, leading to a faster return on investment (ROI) in long-term applications. Your choice should weigh immediate budget constraints against potential savings and ROI through improved thermal performance.

Choosing the Right System for Your Needs

Direct injection systems provide efficient heat transfer by mixing heating fluid directly with the target medium, ideal for applications requiring rapid temperature changes. Plate heat exchangers utilize multiple thin plates to transfer heat between fluids without mixing, offering superior hygiene and easier maintenance for processes needing separation. Your choice depends on factors such as fluid compatibility, temperature control precision, and maintenance requirements, ensuring optimal performance and longevity.

Direct injection vs plate heat exchange Infographic

libmatt.com

libmatt.com