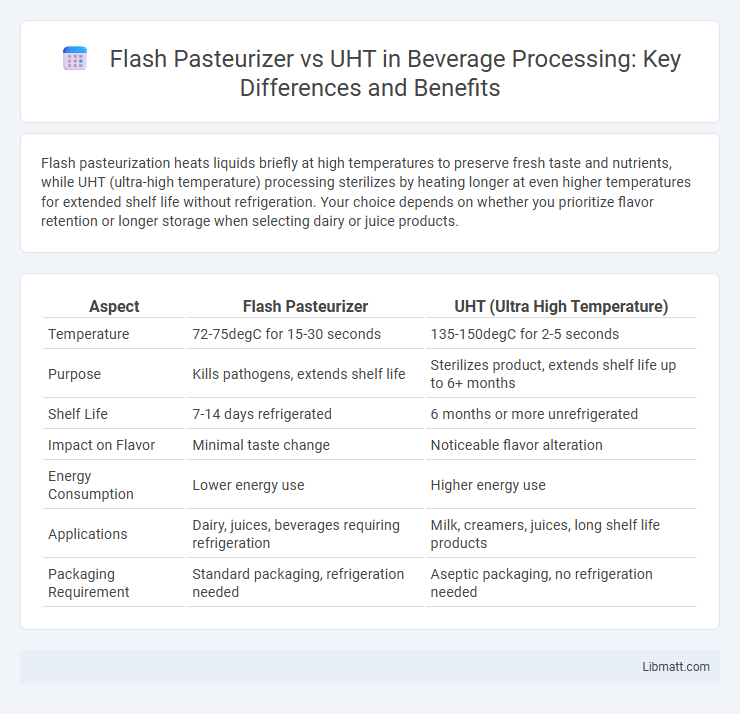

Flash pasteurization heats liquids briefly at high temperatures to preserve fresh taste and nutrients, while UHT (ultra-high temperature) processing sterilizes by heating longer at even higher temperatures for extended shelf life without refrigeration. Your choice depends on whether you prioritize flavor retention or longer storage when selecting dairy or juice products.

Table of Comparison

| Aspect | Flash Pasteurizer | UHT (Ultra High Temperature) |

|---|---|---|

| Temperature | 72-75degC for 15-30 seconds | 135-150degC for 2-5 seconds |

| Purpose | Kills pathogens, extends shelf life | Sterilizes product, extends shelf life up to 6+ months |

| Shelf Life | 7-14 days refrigerated | 6 months or more unrefrigerated |

| Impact on Flavor | Minimal taste change | Noticeable flavor alteration |

| Energy Consumption | Lower energy use | Higher energy use |

| Applications | Dairy, juices, beverages requiring refrigeration | Milk, creamers, juices, long shelf life products |

| Packaging Requirement | Standard packaging, refrigeration needed | Aseptic packaging, no refrigeration needed |

Understanding Flash Pasteurization

Flash pasteurization rapidly heats liquid products to approximately 72degC for 15-30 seconds, effectively eliminating harmful microorganisms while preserving flavor and nutritional quality. This method contrasts with Ultra-High Temperature (UHT) processing, which heats products above 135degC for 2-5 seconds, resulting in longer shelf life but potential changes in taste and texture. Flash pasteurization is commonly used for fresh juices, dairy, and beverages requiring minimal heat impact and a refrigerated shelf life.

What is UHT (Ultra-High Temperature) Processing?

UHT (Ultra-High Temperature) processing involves heating liquid foods, such as milk or juice, to temperatures above 135degC (275degF) for a few seconds to achieve sterilization, ensuring extended shelf life without refrigeration. This method effectively eliminates spores and bacteria while preserving nutrients and taste, unlike traditional flash pasteurization which heats products to lower temperatures around 72degC (161degF) for 15 seconds. Your choice between UHT and flash pasteurization depends on storage needs, with UHT providing longer-lasting products ideal for shelf-stable packaging.

Key Differences Between Flash Pasteurizer and UHT

Flash pasteurization heats liquids to 71.5degC (160degF) for 15-30 seconds, preserving most natural flavors and nutrients, while UHT (Ultra-High Temperature) processing sterilizes by heating to 135-150degC (275-302degF) for 2-5 seconds, resulting in longer shelf life but slight taste alteration. Flash pasteurizers are ideal for refrigerated products with shorter shelf life, whereas UHT-treated products can be stored unrefrigerated for several months. The key differences lie in processing temperature, duration, product shelf life, and impact on flavor and nutritional quality.

Temperature and Time: Flash vs. UHT

Flash pasteurization heats liquid to 71-75degC for 15-30 seconds, preserving more natural flavor and nutrients due to the shorter exposure time. UHT (Ultra-High Temperature) processing rapidly heats liquid to 135-150degC for 2-5 seconds, resulting in extended shelf life but potential changes in taste and nutritional profile. Your choice between Flash and UHT depends on balancing product quality with storage requirements and shelf stability.

Impact on Nutritional Value

Flash pasteurization preserves more heat-sensitive vitamins such as vitamin C and B-complex due to its short exposure to high temperature, maintaining better nutritional value in dairy and juice products. UHT (Ultra-High Temperature) processing, while extending shelf life significantly, can cause a greater reduction in certain nutrients, including some antioxidants and enzymes sensitive to intense heat. Your choice between Flash pasteurizer and UHT impacts the balance between nutritional retention and product longevity.

Effects on Taste and Flavor

Flash pasteurization preserves the natural taste and flavor of beverages better than UHT processing by using lower temperatures for a shorter time, minimizing heat-induced flavor changes. UHT treatment, though effective for sterilization and extended shelf life, often imparts a cooked or caramelized taste due to higher temperatures and longer exposure times. Your choice between Flash pasteurizer and UHT will significantly impact the sensory profile and freshness perceived in the final product.

Shelf Life Comparison

Flash pasteurization extends shelf life to approximately 2-3 weeks when refrigerated, preserving more natural flavor and nutrients compared to UHT. Ultra-High Temperature (UHT) processing provides a significantly longer shelf life of 6-9 months at ambient temperature, ideal for long-term storage without refrigeration. Although UHT offers convenience and extended durability, flash pasteurization maintains higher sensory and nutritional quality for shorter-term consumption.

Application in the Food and Beverage Industry

Flash pasteurizers are widely used for heat-sensitive beverages like fruit juices and dairy products, balancing microbial safety with flavor preservation due to their short heating times. UHT (Ultra-High Temperature) processing extends shelf life significantly for milk, cream, and liquid eggs, allowing storage without refrigeration by sterilizing products at temperatures above 135degC for a few seconds. Both technologies are critical in the food and beverage industry for ensuring safety and quality, with flash pasteurization preferred for taste retention and UHT favored for long-term storage and distribution efficiency.

Equipment and Cost Considerations

Flash pasteurizers utilize continuous flow equipment, requiring moderate initial investment and lower maintenance expenses, making them suitable for medium-scale production. UHT systems demand advanced, high-pressure homogenizers and aseptic filling equipment, resulting in significantly higher costs but offering extended shelf life and minimal refrigeration needs. Choosing between your options depends on balancing equipment affordability against long-term operational savings and product distribution requirements.

Choosing the Right Method for Your Product

Flash pasteurization preserves the fresh taste and nutritional quality of beverages by rapidly heating and cooling, ideal for products like fruit juices and dairy. UHT (Ultra-High Temperature) processing extends shelf life up to six months without refrigeration, making it suitable for long-lasting products such as milk and creamers. Selecting between flash pasteurization and UHT depends on balancing factors like desired shelf life, flavor retention, and distribution logistics.

Flash pasteurizer vs UHT Infographic

libmatt.com

libmatt.com