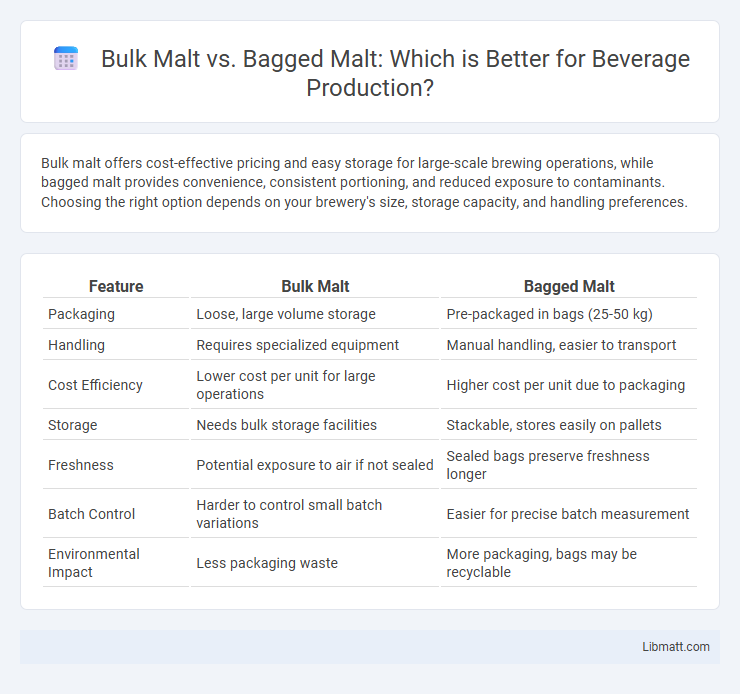

Bulk malt offers cost-effective pricing and easy storage for large-scale brewing operations, while bagged malt provides convenience, consistent portioning, and reduced exposure to contaminants. Choosing the right option depends on your brewery's size, storage capacity, and handling preferences.

Table of Comparison

| Feature | Bulk Malt | Bagged Malt |

|---|---|---|

| Packaging | Loose, large volume storage | Pre-packaged in bags (25-50 kg) |

| Handling | Requires specialized equipment | Manual handling, easier to transport |

| Cost Efficiency | Lower cost per unit for large operations | Higher cost per unit due to packaging |

| Storage | Needs bulk storage facilities | Stackable, stores easily on pallets |

| Freshness | Potential exposure to air if not sealed | Sealed bags preserve freshness longer |

| Batch Control | Harder to control small batch variations | Easier for precise batch measurement |

| Environmental Impact | Less packaging waste | More packaging, bags may be recyclable |

Understanding Bulk Malt and Bagged Malt

Bulk malt is typically delivered in large quantities without packaging, allowing breweries to reduce costs and customize storage according to production needs. Bagged malt comes pre-packaged in standard-sized bags, offering easier handling, precise portion control, and enhanced protection against moisture and contamination. Both forms impact malt freshness, storage logistics, and pricing strategies in brewing operations.

Key Differences Between Bulk and Bagged Malt

Bulk malt offers cost-efficiency and is ideal for large-scale brewing operations due to its loose, unpackaged form, which simplifies storage and handling. Bagged malt provides convenience and protection from contamination with pre-measured, sealed bags that ensure consistent quality and easier inventory control. The choice depends on batch size, storage capacity, and quality management preferences in the brewing process.

Cost Comparison: Bulk Malt vs Bagged Malt

Bulk malt typically offers a lower cost per pound compared to bagged malt due to reduced packaging and handling expenses, making it a more economical choice for large-scale breweries. Bagged malt incurs higher costs because of individual packaging, increased labor for handling, and potential storage inefficiencies. Brewers seeking to minimize ingredient expenses often prefer bulk malt for its cost-effectiveness and streamlined supply chain benefits.

Storage Requirements and Solutions

Bulk malt requires extensive, climate-controlled storage facilities to maintain quality and prevent moisture absorption or pest infestation. Bagged malt offers convenient, smaller packaging that facilitates easier handling and segmented storage, reducing spoilage risk. Your choice depends on available storage space and handling capabilities, with bulk malt best suited for large-scale operations and bagged malt ideal for smaller batches or varied malt types.

Impact on Brewing Efficiency

Bulk malt improves brewing efficiency by reducing handling time and minimizing the risk of contamination, leading to consistent mash quality. Bagged malt offers convenience and portion control but may increase labor and waste, slightly lowering overall efficiency. For your brewery, choosing bulk malt can optimize production speed and cost-effectiveness while maintaining product quality.

Quality and Freshness Considerations

Bulk malt often provides greater freshness due to faster turnover in commercial breweries, minimizing exposure to oxygen and moisture that can degrade quality. Bagged malt offers more controlled packaging, reducing contamination risk and maintaining consistent moisture levels during storage. Both formats require proper handling and storage conditions to preserve malt quality and ensure optimal brewing performance.

Environmental Impact: Packaging and Waste

Bulk malt significantly reduces environmental impact by minimizing packaging waste compared to bagged malt, which typically involves single-use plastic or paper bags that contribute to landfill volume. Using bulk malt supports sustainability efforts by lowering the demand for packaging materials, thus decreasing carbon emissions from production and disposal processes. You can make an eco-friendly choice by selecting bulk malt, which helps reduce packaging waste and promotes a greener brewing supply chain.

Handling and Transportation Logistics

Bulk malt offers streamlined handling and transportation logistics by reducing packaging waste and minimizing loading times, which lowers overall freight costs. Bagged malt requires more labor-intensive handling due to individual sacks needing manual loading and unloading, increasing the risk of damage and contamination during transit. Efficient logistics planning for bulk malt supports faster processing and better inventory management in breweries.

Suitability for Different Brewery Sizes

Bulk malt provides cost efficiency and ease of handling, making it ideal for large breweries with high production volumes and established storage facilities. Bagged malt, offering better portion control and reduced risk of contamination, suits smaller breweries or craft breweries that require flexibility and precision in malt usage. Your brewery size and operational capacity will determine whether bulk or bagged malt best supports efficient brewing processes.

Making the Right Choice for Your Brewery

Choosing between bulk malt and bagged malt significantly impacts your brewery's efficiency and cost management. Bulk malt offers economies of scale and reduces waste, ideal for larger breweries with consistent production volumes, while bagged malt provides flexibility and easier handling, suitable for smaller operations or craft brewers experimenting with recipes. Your choice should align with your brewery's production needs, storage capacity, and quality control priorities to optimize both flavor consistency and operational workflow.

Bulk malt vs bagged malt Infographic

libmatt.com

libmatt.com