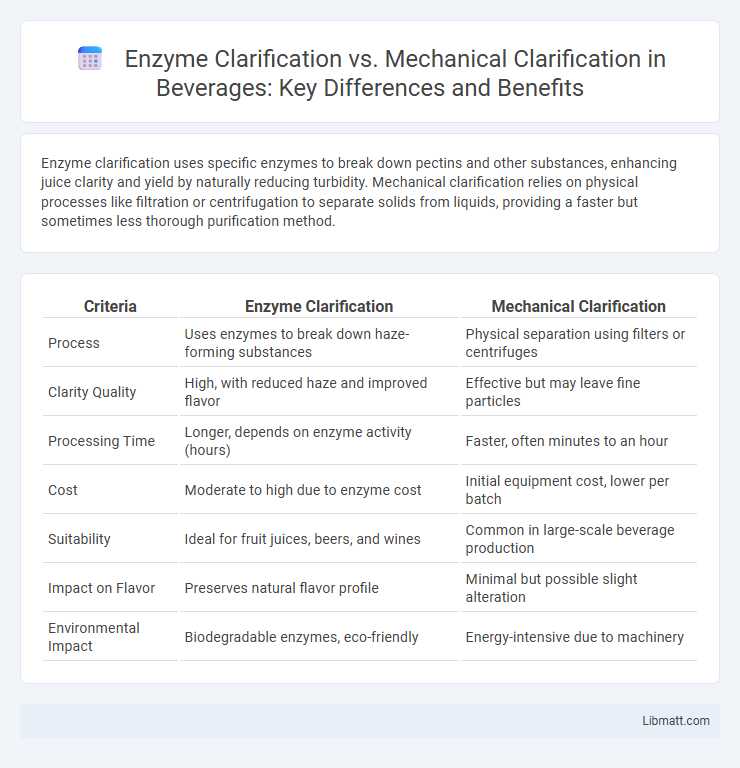

Enzyme clarification uses specific enzymes to break down pectins and other substances, enhancing juice clarity and yield by naturally reducing turbidity. Mechanical clarification relies on physical processes like filtration or centrifugation to separate solids from liquids, providing a faster but sometimes less thorough purification method.

Table of Comparison

| Criteria | Enzyme Clarification | Mechanical Clarification |

|---|---|---|

| Process | Uses enzymes to break down haze-forming substances | Physical separation using filters or centrifuges |

| Clarity Quality | High, with reduced haze and improved flavor | Effective but may leave fine particles |

| Processing Time | Longer, depends on enzyme activity (hours) | Faster, often minutes to an hour |

| Cost | Moderate to high due to enzyme cost | Initial equipment cost, lower per batch |

| Suitability | Ideal for fruit juices, beers, and wines | Common in large-scale beverage production |

| Impact on Flavor | Preserves natural flavor profile | Minimal but possible slight alteration |

| Environmental Impact | Biodegradable enzymes, eco-friendly | Energy-intensive due to machinery |

Introduction to Clarification Methods

Clarification methods in water and wastewater treatment primarily include enzyme clarification and mechanical clarification, both aimed at removing suspended solids and impurities to enhance water quality. Enzyme clarification uses specific enzymes to break down organic matter, promoting faster sedimentation and improved clarity, while mechanical clarification relies on physical processes such as sedimentation, filtration, and centrifugation to separate solids from liquids. Selecting between these methods depends on factors like wastewater composition, treatment goals, operational costs, and desired effluent standards.

Understanding Enzyme Clarification

Enzyme clarification utilizes specific enzymes to break down complex organic molecules in juice or liquid, enhancing clarity by accelerating sedimentation and reducing haze. In contrast, mechanical clarification relies on physical processes such as centrifugation or filtration to separate solids from liquids without altering the chemical composition of the product. Enzyme clarification improves yield and quality by targeting pectins and proteins that cause turbidity, making it a preferred choice in fruit juice and wine production for achieving superior clarity.

Overview of Mechanical Clarification

Mechanical clarification employs physical processes such as centrifugation, filtration, or sedimentation to separate solids from liquids, effectively removing suspended particles. This method offers rapid processing and is suitable for large-scale operations where enzyme use may be cost-prohibitive. Your choice of mechanical clarification can enhance efficiency in wastewater treatment and industrial liquid purification by minimizing downtime and operational complexity.

Key Differences Between Enzyme and Mechanical Clarification

Enzyme clarification uses biological catalysts to break down impurities and improve juice or wine clarity, enhancing flavor and stability, while mechanical clarification relies on physical processes like filtration or centrifugation to separate solids from liquids. Enzymatic treatment often results in finer particle removal and improved processing efficiency, whereas mechanical methods provide rapid separation but may leave behind micro-particulates. Understanding these key differences helps you choose the most effective clarification method based on your product quality goals and processing capabilities.

Efficiency and Effectiveness Comparison

Enzyme clarification significantly improves efficiency by accelerating the breakdown of suspended solids, resulting in faster sedimentation and clearer supernatant compared to mechanical clarification. Mechanical clarification relies on physical processes such as centrifugation or sedimentation, which often require more energy and longer processing times. Enzyme-based methods enhance overall effectiveness by targeting specific organic compounds, leading to higher clarity and reduced chemical usage, whereas mechanical methods may leave finer particulates unsettled.

Impact on Product Quality

Enzyme clarification enhances product quality by precisely breaking down pectins and other haze-forming compounds, resulting in clearer, more stable beverages with improved flavor and aroma profiles. Mechanical clarification methods, such as centrifugation or filtration, physically remove suspended solids but may also strip desirable flavor compounds and negatively affect mouthfeel. Your choice between these techniques directly influences the clarity, taste, and overall sensory experience of the final product.

Cost Considerations

Enzyme clarification typically involves higher upfront costs due to specialized biochemical reagents but offers long-term savings through reduced energy consumption and lower chemical usage compared to mechanical clarification. Mechanical clarification requires substantial capital investment in equipment such as centrifuges or filters, along with ongoing maintenance expenses and higher operational energy costs. Assessing total cost of ownership reveals enzyme clarification can be more cost-effective for processes emphasizing efficiency and sustainability.

Environmental and Sustainability Factors

Enzyme clarification in wastewater treatment reduces chemical usage and energy consumption, lowering environmental impact compared to mechanical clarification, which often relies on energy-intensive equipment and chemical coagulants. Enzymatic processes promote biodegradability and produce less sludge, minimizing disposal challenges and enhancing sustainability. Mechanical clarification typically generates more solid waste and requires frequent maintenance, increasing operational carbon footprint and resource use.

Applications in Various Industries

Enzyme clarification is widely used in the food and beverage industry, especially for fruit juices and wines, where it enhances clarity and stability by breaking down pectins and proteins. Mechanical clarification methods, such as centrifugation and filtration, find extensive application in wastewater treatment and brewing industries for efficient solid-liquid separation. Both techniques are essential in pharmaceuticals for purifying biological products but are chosen based on the nature of the raw material and desired purity level.

Choosing the Right Clarification Method

Enzyme clarification enhances juice yield and clarity by breaking down pectins and other polysaccharides, making it ideal for fruit juices with high viscosity and suspended solids. Mechanical clarification, such as centrifugation or filtration, quickly separates solids from liquids without altering juice composition, suitable for clear juices with low particulate content. Choosing the right clarification method depends on factors like juice type, desired clarity, processing time, and cost-efficiency, where enzymatic treatment offers higher quality but requires longer processing, and mechanical methods provide faster results with minimal biochemical impact.

Enzyme clarification vs mechanical clarification Infographic

libmatt.com

libmatt.com