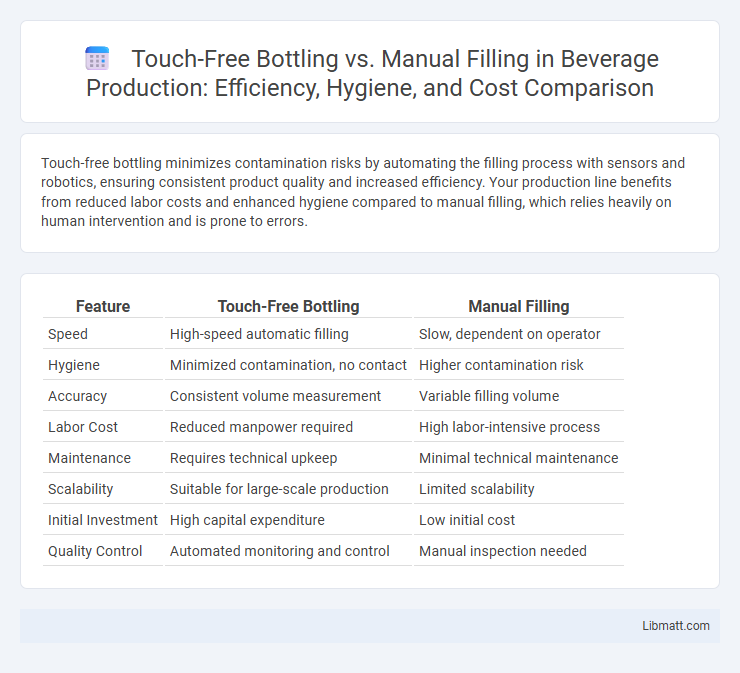

Touch-free bottling minimizes contamination risks by automating the filling process with sensors and robotics, ensuring consistent product quality and increased efficiency. Your production line benefits from reduced labor costs and enhanced hygiene compared to manual filling, which relies heavily on human intervention and is prone to errors.

Table of Comparison

| Feature | Touch-Free Bottling | Manual Filling |

|---|---|---|

| Speed | High-speed automatic filling | Slow, dependent on operator |

| Hygiene | Minimized contamination, no contact | Higher contamination risk |

| Accuracy | Consistent volume measurement | Variable filling volume |

| Labor Cost | Reduced manpower required | High labor-intensive process |

| Maintenance | Requires technical upkeep | Minimal technical maintenance |

| Scalability | Suitable for large-scale production | Limited scalability |

| Initial Investment | High capital expenditure | Low initial cost |

| Quality Control | Automated monitoring and control | Manual inspection needed |

Introduction to Bottling Methods

Touch-free bottling offers a hygienic and efficient alternative to manual filling by eliminating direct contact with containers during the packaging process. This automated method uses advanced sensors and nozzles to accurately dispense liquids, reducing contamination risks and ensuring consistent fill levels. Your production line benefits from improved speed, safety, and product quality compared to traditional manual bottling techniques.

What is Touch-Free Bottling?

Touch-free bottling is an automated packaging technology that eliminates direct contact between the product and the filling equipment, enhancing hygiene and reducing contamination risks. This method uses advanced sensors and robotic arms to precisely dispense liquids into containers without manual intervention. Compared to manual filling, touch-free bottling improves production speed, consistency, and ensures compliance with stringent food, pharmaceutical, and cosmetic industry standards.

Defining Manual Filling Processes

Manual filling processes involve operators physically handling containers and dispensing liquid products using handheld tools or semi-automatic machines, requiring precise hand-eye coordination to ensure accuracy and prevent spillage. These methods are subject to variability due to human error, slower production rates, and increased risk of contamination from direct contact with the product. In contrast, touch-free bottling utilizes automated systems with sensors and robotics to dispense liquids without direct human intervention, enhancing hygiene, consistency, and throughput efficiency in packaging lines.

Accuracy and Consistency Comparison

Touch-free bottling systems deliver superior accuracy by using advanced sensors and automated controls that minimize human error, ensuring consistent fill volumes across large production batches. Manual filling relies heavily on operator skill and attention, leading to variability in fill levels and increased risk of spillage or product waste. Your manufacturing process benefits from touch-free bottling through enhanced precision and uniformity, optimizing product quality and reducing material costs.

Speed and Efficiency: Key Differences

Touch-free bottling systems significantly enhance speed and efficiency by automating the filling process, reducing downtime and minimizing human error compared to manual filling. Your production line benefits from consistent, high-speed operations with precise volume control and reduced contamination risks. Manual filling, while flexible for small batches, often lags in throughput and requires more labor, impacting overall productivity.

Hygiene and Contamination Risks

Touch-free bottling significantly reduces hygiene and contamination risks by minimizing direct contact between operators and the product, which prevents microbial transfer and particulate introduction. Automated systems use sterile environments and controlled air flows to maintain product purity, while manual filling often involves human errors and exposure to contaminants. Implementing touch-free technology ensures higher safety standards in food and beverage production, crucial for meeting strict regulatory requirements.

Labor Requirements and Costs

Touch-free bottling significantly reduces labor requirements by automating the filling process, leading to lower operational costs and minimizing human error. Manual filling demands extensive human labor, increasing wage expenses and the potential for inconsistencies that can affect product quality. Investing in touch-free bottling technology offers long-term savings and improved efficiency compared to the higher recurrent costs and variability associated with manual filling.

Scalability for Growing Businesses

Touch-free bottling offers superior scalability for growing businesses by minimizing human error and increasing production speed, allowing your operations to expand without compromising quality. Manual filling, while cost-effective for small batches, struggles to keep pace with higher volumes and often requires additional labor, limiting scalability. Investing in automated touch-free systems supports consistent output and easier adaptation to market demand shifts.

Sustainability and Resource Usage

Touch-free bottling significantly reduces resource consumption by minimizing product waste and eliminating the need for cleaning solvents and sanitizing agents typically required in manual filling. This automated process enhances sustainability through precise dosing, lowering water and energy usage associated with manual cleaning cycles. Reduced contamination risk decreases spoilage rates, contributing to lower environmental impact and improved resource efficiency in beverage and pharmaceutical industries.

Choosing the Right Bottling Method

Choosing the right bottling method depends on production volume, hygiene requirements, and budget considerations. Touch-free bottling systems offer higher accuracy, reduced contamination risk, and faster throughput ideal for large-scale operations. Manual filling suits small batches and artisanal products, providing flexibility but increasing labor costs and error potential.

Touch-free bottling vs manual filling Infographic

libmatt.com

libmatt.com