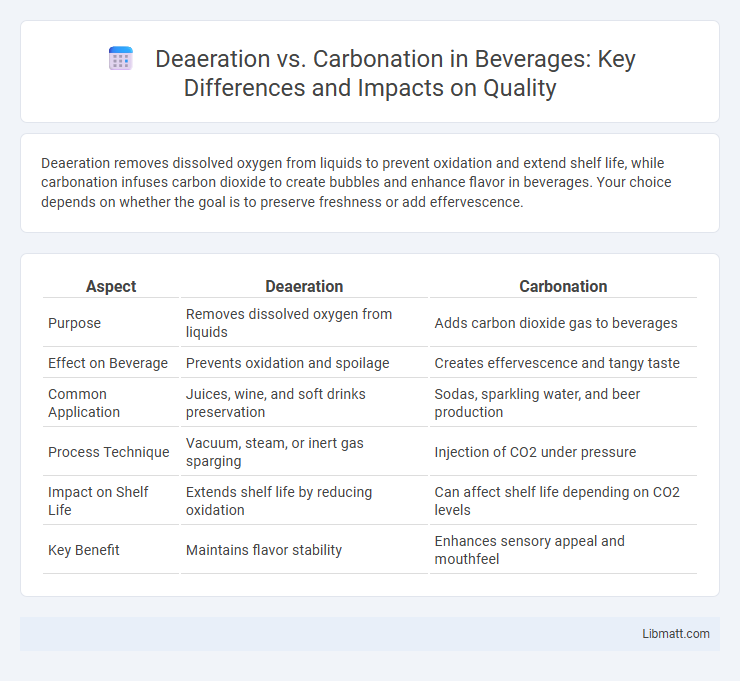

Deaeration removes dissolved oxygen from liquids to prevent oxidation and extend shelf life, while carbonation infuses carbon dioxide to create bubbles and enhance flavor in beverages. Your choice depends on whether the goal is to preserve freshness or add effervescence.

Table of Comparison

| Aspect | Deaeration | Carbonation |

|---|---|---|

| Purpose | Removes dissolved oxygen from liquids | Adds carbon dioxide gas to beverages |

| Effect on Beverage | Prevents oxidation and spoilage | Creates effervescence and tangy taste |

| Common Application | Juices, wine, and soft drinks preservation | Sodas, sparkling water, and beer production |

| Process Technique | Vacuum, steam, or inert gas sparging | Injection of CO2 under pressure |

| Impact on Shelf Life | Extends shelf life by reducing oxidation | Can affect shelf life depending on CO2 levels |

| Key Benefit | Maintains flavor stability | Enhances sensory appeal and mouthfeel |

Understanding Deaeration: Definition and Purpose

Deaeration is the process of removing dissolved oxygen and other gases from liquids, primarily in water treatment and beverage production, to prevent oxidation and microbial growth. This technique enhances product stability, extends shelf life, and improves taste by reducing oxygen-related spoilage. In contrast, carbonation involves adding carbon dioxide to liquids to create effervescence and acidity, commonly used in soft drinks and sparkling waters.

What is Carbonation? Core Concepts Explained

Carbonation is the process of dissolving carbon dioxide (CO2) gas into a liquid, typically under pressure, to create carbonic acid, which imparts effervescence and a tangy flavor to beverages such as soda and sparkling water. This chemical reaction enhances both the sensory experience and shelf life of drinks by increasing acidity and creating bubbles that affect mouthfeel and aroma release. Understanding carbonation contrasts with deaeration, which involves the removal of gases like oxygen to prevent oxidation and spoilage in liquids.

Key Differences Between Deaeration and Carbonation

Deaeration is the process of removing dissolved oxygen and other gases from liquids to prevent oxidation and improve product stability, while carbonation involves dissolving carbon dioxide into a liquid to create bubbles and enhance taste or texture. Deaeration primarily targets oxygen removal for preservation, whereas carbonation adds CO2 for sensory and preservation benefits. Understanding these key differences helps you choose the appropriate method for beverage production or industrial applications.

The Science Behind Deaeration Processes

Deaeration removes dissolved oxygen and other gases from liquids, primarily through heating and vacuum techniques, preventing oxidation and microbial growth in beverages and industrial fluids. Carbonation introduces carbon dioxide into liquids, enhancing flavor and preservation in products like sodas and sparkling water. Understanding your deaeration process ensures improved product stability and longevity by minimizing oxygen-related spoilage.

Carbonation Methods in Beverage Production

Carbonation methods in beverage production primarily include natural fermentation, forced carbonation, and carbonation through CO2 injection, each influencing the beverage's texture and flavor profile. Deaeration, the removal of dissolved oxygen, is crucial before carbonation to prevent oxidation and preserve the beverage's freshness and shelf life. Your choice of carbonation technique directly affects the effervescence intensity, taste balance, and overall consumer experience.

Benefits of Deaeration in Food and Beverage Industries

Deaeration significantly enhances product quality by removing dissolved oxygen, which prevents oxidation and prolongs shelf life in food and beverage industries. This process maintains flavor integrity and color stability, ensuring your products stay fresh and appealing to consumers. By minimizing oxidative deterioration, deaeration also reduces spoilage, cutting costs related to waste and extending marketability.

Advantages and Uses of Carbonation

Carbonation enhances beverage flavor and shelf life by infusing carbon dioxide, which creates effervescence and a refreshing taste favored in soft drinks and sparkling waters. The process also helps inhibit microbial growth, extending product stability without chemical preservatives. Carbonated water serves as a versatile base in the food and beverage industry, widely used in mixers, sodas, and artisanal sparkling drinks.

Deaeration vs Carbonation: Impact on Flavor and Quality

Deaeration removes dissolved oxygen from liquids, preventing oxidation and preserving the original flavor and freshness of beverages, which enhances overall product quality. Carbonation introduces carbon dioxide, creating effervescence that adds a sharp, tangy taste and improves mouthfeel but may alter the beverage's flavor profile. Balancing deaeration and carbonation processes is crucial for maintaining desired taste characteristics and extending shelf life in beverages like beer, sparkling water, and soft drinks.

Industrial Applications: When to Use Deaeration or Carbonation

Deaeration is essential in industrial applications requiring the removal of dissolved oxygen and gases to prevent corrosion and oxidation, commonly used in boiler feedwater treatment, food and beverage preservation, and pharmaceutical manufacturing. Carbonation is primarily applied in the production of carbonated beverages, water treatment processes, and enhancing chemical reactions where dissolved carbon dioxide is needed. Choosing between deaeration and carbonation depends on whether the application demands gas removal or controlled gas addition to achieve process stability and product quality.

Choosing the Right Process: Deaeration vs Carbonation

Choosing between deaeration and carbonation depends on the specific industry needs and product quality goals. Deaeration removes dissolved oxygen to prevent oxidation and extend shelf life, essential in pharmaceutical, beverage, and food industries. Carbonation introduces carbon dioxide for flavor enhancement and preservation, widely used in soft drinks and sparkling water production.

Deaeration vs carbonation Infographic

libmatt.com

libmatt.com