Nitrogen dosing adjusts pH levels by reducing carbonate hardness without increasing CO2 concentration, making it ideal for sensitive aquatic plants and fish. Your choice between nitrogen dosing and CO2 dosing depends on the specific needs of your aquarium ecosystem and your goals for maintaining water chemistry balance.

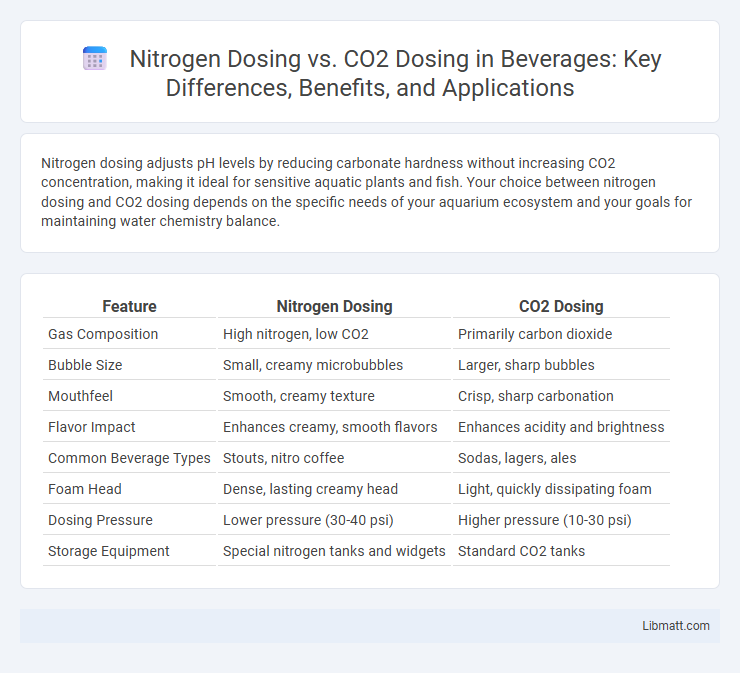

Table of Comparison

| Feature | Nitrogen Dosing | CO2 Dosing |

|---|---|---|

| Gas Composition | High nitrogen, low CO2 | Primarily carbon dioxide |

| Bubble Size | Small, creamy microbubbles | Larger, sharp bubbles |

| Mouthfeel | Smooth, creamy texture | Crisp, sharp carbonation |

| Flavor Impact | Enhances creamy, smooth flavors | Enhances acidity and brightness |

| Common Beverage Types | Stouts, nitro coffee | Sodas, lagers, ales |

| Foam Head | Dense, lasting creamy head | Light, quickly dissipating foam |

| Dosing Pressure | Lower pressure (30-40 psi) | Higher pressure (10-30 psi) |

| Storage Equipment | Special nitrogen tanks and widgets | Standard CO2 tanks |

Introduction to Nitrogen and CO2 Dosing

Nitrogen dosing introduces inert gas into liquids to reduce oxygen levels, enhancing freshness and preventing oxidation, especially in beer and wine preservation. CO2 dosing carbonates beverages, creating effervescence and influencing taste and mouthfeel in sodas and sparkling drinks. Understanding your choice between nitrogen and CO2 dosing depends on desired texture, flavor, and shelf life.

How Nitrogen Dosing Works

Nitrogen dosing works by injecting nitrogen gas into a beverage to create smaller bubbles, resulting in a smoother, creamier texture compared to CO2 dosing. Unlike CO2, which adds carbonation and a tangy taste, nitrogen remains largely insoluble, producing a rich mouthfeel without the sharpness of carbonation. Your choice between nitrogen and CO2 dosing depends on the desired texture and flavor profile in drinks like stouts or sparkling waters.

Understanding CO2 Dosing Methods

CO2 dosing methods vary between pressurized systems and DIY yeast reactors, each offering different levels of control and efficiency for aquatic plant growth. Nitrogen dosing, while crucial for plant nutrition, does not influence pH or carbonate hardness like CO2, which directly affects photosynthesis rates and plant health in aquariums. Understanding your aquarium's specific CO2 requirements helps optimize carbon levels, ensuring balanced nutrient availability and vibrant plant development.

Comparing Nitrogen vs CO2 in Beverage Applications

Nitrogen dosing creates smaller bubbles that result in a smoother, creamier texture compared to CO2, which produces larger bubbles and a sharper, more acidic mouthfeel. Your choice between nitrogen and CO2 impacts the carbonation level, shelf life, and flavor profile of beverages like stouts, lagers, and sparkling waters. Nitrogen is ideal for enhancing mouthfeel and reducing acidity, while CO2 offers more pronounced effervescence and tanginess in carbonated drinks.

Benefits of Nitrogen Dosing

Nitrogen dosing in aquariums provides enhanced control over water chemistry by stabilizing pH levels and reducing algae growth more effectively than CO2 dosing. It promotes healthier aquatic plant growth by supplying a vital nutrient that supports protein synthesis and chlorophyll production. Nitrogen also minimizes fluctuations in dissolved oxygen, creating a balanced environment for fish and plants.

Advantages of CO2 Dosing

CO2 dosing provides precise pH control in aquariums and hydroponic systems, promoting optimal plant growth and nutrient absorption. It enhances photosynthesis efficiency by increasing carbon availability, resulting in healthier, more vibrant plants. Your aquatic environment benefits from improved oxygen levels and reduced algae growth compared to nitrogen dosing.

Impact on Taste and Texture

Nitrogen dosing creates smaller, denser bubbles that deliver a creamier mouthfeel and smoother texture, enhancing the sensory experience of stouts and ales. CO2 dosing produces sharper, more effervescent carbonation, resulting in a tangier taste and brisker texture often preferred in lagers and pilsners. Your choice between nitrogen and CO2 dosing directly influences the beer's flavor profile and carbonation, tailoring it to your preferred drinking experience.

Equipment and Implementation Requirements

Nitrogen dosing systems typically require gas cylinders or generators, regulators, precision flow meters, and appropriate injection valves to accurately control nitrogen levels in beverages or other applications. In contrast, CO2 dosing setups demand pressurized CO2 tanks, pressure regulators, solenoid valves, and specialized carbonation equipment to maintain desired carbonation and acidity levels. Proper installation of both systems must consider safety measures for handling pressurized gases, inline monitoring sensors for concentration accuracy, and compatibility with the targeted medium to ensure optimal dosing performance.

Cost Considerations for Nitrogen and CO2 Dosing

Nitrogen dosing generally incurs lower costs due to nitrogen's abundance in the atmosphere and less complex handling requirements compared to CO2, which often requires specialized equipment for pressurization and injection. CO2 dosing involves higher operational expenses linked to gas capture, transportation, and storage, especially when sourced from industrial processes or direct air capture. Budgeting for dosing systems must account for initial capital investment and ongoing maintenance, where nitrogen systems typically exhibit lower total cost of ownership than CO2 systems.

Choosing the Right Dosing Method for Your Needs

Choosing between nitrogen dosing and CO2 dosing depends on your specific application and desired effects. Nitrogen dosing is ideal for beverages requiring gentle carbonation and stable foam, such as stouts and certain craft beers, because it produces smaller bubbles and a creamier mouthfeel. CO2 dosing is preferred for standard carbonation levels, offering sharper carbonation and longer shelf life in sodas, beers, and sparkling waters.

Nitrogen dosing vs CO2 dosing Infographic

libmatt.com

libmatt.com