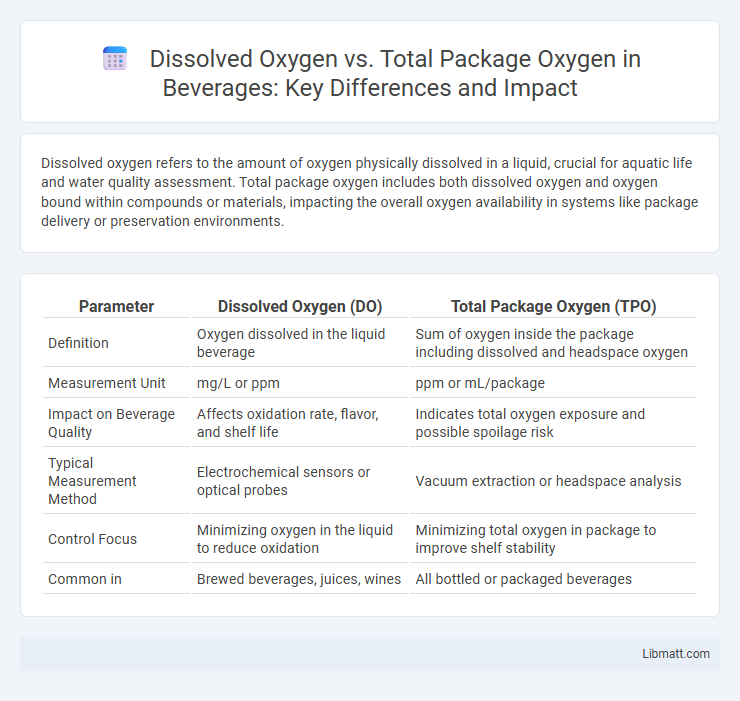

Dissolved oxygen refers to the amount of oxygen physically dissolved in a liquid, crucial for aquatic life and water quality assessment. Total package oxygen includes both dissolved oxygen and oxygen bound within compounds or materials, impacting the overall oxygen availability in systems like package delivery or preservation environments.

Table of Comparison

| Parameter | Dissolved Oxygen (DO) | Total Package Oxygen (TPO) |

|---|---|---|

| Definition | Oxygen dissolved in the liquid beverage | Sum of oxygen inside the package including dissolved and headspace oxygen |

| Measurement Unit | mg/L or ppm | ppm or mL/package |

| Impact on Beverage Quality | Affects oxidation rate, flavor, and shelf life | Indicates total oxygen exposure and possible spoilage risk |

| Typical Measurement Method | Electrochemical sensors or optical probes | Vacuum extraction or headspace analysis |

| Control Focus | Minimizing oxygen in the liquid to reduce oxidation | Minimizing total oxygen in package to improve shelf stability |

| Common in | Brewed beverages, juices, wines | All bottled or packaged beverages |

Introduction to Dissolved Oxygen and Total Package Oxygen

Dissolved oxygen (DO) measures the amount of oxygen available in water for aquatic organisms, essential for maintaining healthy ecosystems and preventing hypoxia. Total package oxygen (TPO) refers to the combined oxygen content in a beverage, including both dissolved and chemically bound forms, critical for product stability and flavor preservation. Understanding the differences between DO and TPO helps you optimize water quality and enhance beverage manufacturing processes.

Importance of Oxygen Control in Beverages

Maintaining precise dissolved oxygen levels in beverages is critical for preserving flavor, aroma, and shelf life, as excess oxygen accelerates oxidation and microbial growth. Total package oxygen, which includes dissolved and headspace oxygen, must be minimized through advanced packaging technologies to ensure product stability and consumer safety. Effective oxygen control enhances beverage quality, reduces spoilage risks, and extends marketable lifespan in competitive beverage industries.

What is Dissolved Oxygen (DO)?

Dissolved oxygen (DO) refers to the amount of oxygen molecules dissolved in water, crucial for aquatic life and biological processes. It differs from total package oxygen, which includes all oxygen forms present in a sample, such as oxygen bound in chemical compounds. Monitoring DO levels helps assess water quality, ecosystem health, and is vital for wastewater treatment and aquatic environments.

What is Total Package Oxygen (TPO)?

Total Package Oxygen (TPO) measures the combined amount of dissolved oxygen and oxygen bound to other compounds within a beverage, typically beer or wine, impacting its flavor stability and shelf life. Unlike Dissolved Oxygen (DO), which only quantifies free oxygen molecules in the liquid phase, TPO accounts for both dissolved oxygen and oxygen present in the headspace of packaging. Monitoring TPO is crucial for maintaining product quality during production and packaging processes, as excess oxygen leads to oxidation and spoilage.

Key Differences Between DO and TPO

Dissolved oxygen (DO) measures the amount of oxygen dissolved directly in water, essential for aquatic life and biochemical reactions, while total package oxygen (TPO) encompasses all forms of oxygen, including dissolved, gaseous, and chemically bound oxygen in packaging environments. DO is expressed in mg/L or ppm reflecting water quality, whereas TPO often relates to packaged product integrity and preservation by accounting for oxygen that affects shelf life and spoilage. Key differences include measurement context, with DO critical in environmental monitoring and TPO focused on industrial applications like food packaging and pharmaceuticals.

Methods for Measuring Dissolved Oxygen

Methods for measuring dissolved oxygen include electrochemical sensors such as polarographic and galvanic probes, which provide real-time data by detecting oxygen reduction at the electrode surface. Optical sensors, utilizing luminescence quenching technology, offer a non-invasive measurement with high sensitivity and minimal maintenance, ideal for continuous monitoring in bioprocesses. Your choice between these methods depends on application requirements, accuracy needs, and environmental conditions affecting sensor performance.

Techniques for Measuring Total Package Oxygen

Techniques for measuring total package oxygen include vacuum extraction, headspace analysis, and chemical sensors such as electrochemical and optical sensors. Vacuum extraction methods involve creating a vacuum inside the package to extract and quantify oxygen content accurately. Optical sensors, based on fluorescence quenching, provide non-destructive, real-time measurements of total oxygen within sealed packages, enhancing quality control in food and pharmaceutical industries.

Impact of DO and TPO on Product Quality and Shelf Life

Dissolved oxygen (DO) directly affects microbial growth and oxidation rates, influencing product spoilage and sensory attributes, while total package oxygen (TPO) accounts for all oxygen present, including headspace and packaging materials. Elevated DO levels accelerate lipid oxidation and enzymatic browning, reducing shelf life and compromising freshness, whereas high TPO indicates potential oxygen ingress that undermines barrier integrity and promotes degradation. Controlling both DO and TPO is critical for maintaining product quality, extending shelf life, and ensuring safety in oxygen-sensitive food and pharmaceutical products.

Strategies to Minimize Oxygen in Packaging

Minimizing oxygen in packaging involves using oxygen scavengers and vacuum sealing techniques to reduce dissolved oxygen levels and total package oxygen content, thus extending shelf life. Incorporating inert gas flushing, such as nitrogen or carbon dioxide, displaces oxygen inside the package, effectively lowering oxygen concentrations. Selecting barrier films with low oxygen transmission rates also plays a critical role in controlling total package oxygen and preventing oxidative spoilage.

Conclusion: Choosing Between DO and TPO Analysis

Dissolved oxygen (DO) measures the amount of oxygen freely available in water, essential for aquatic life and environmental monitoring, while total package oxygen (TPO) captures both dissolved and chemically bound oxygen in a sample. Your choice between DO and TPO analysis depends on the specific application: DO is critical for assessing immediate oxygen availability, whereas TPO provides a comprehensive view of total oxygen content including potential oxygen demand. Typically, DO analysis is preferred for real-time water quality monitoring, whereas TPO is vital for understanding overall oxidative processes and possible oxygen-consuming reactions.

Dissolved oxygen vs total package oxygen Infographic

libmatt.com

libmatt.com