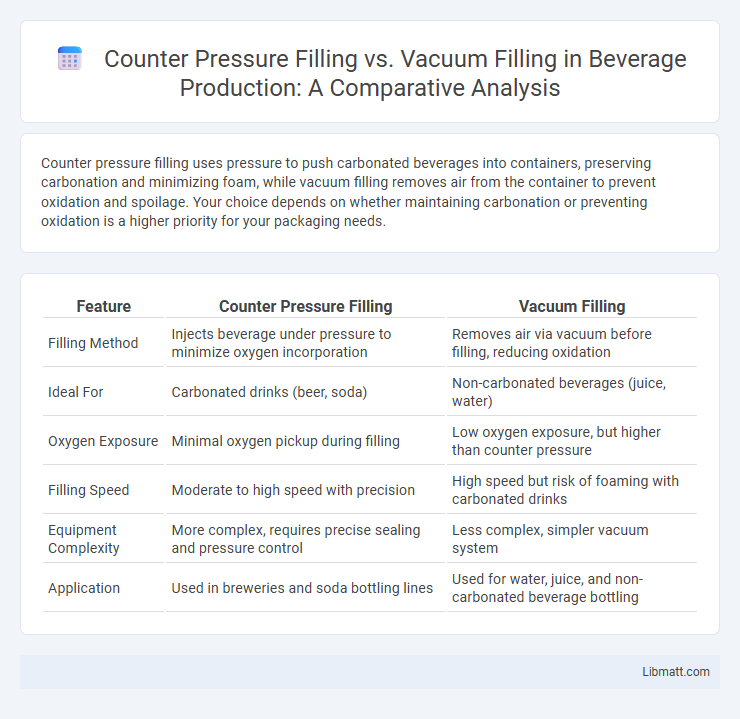

Counter pressure filling uses pressure to push carbonated beverages into containers, preserving carbonation and minimizing foam, while vacuum filling removes air from the container to prevent oxidation and spoilage. Your choice depends on whether maintaining carbonation or preventing oxidation is a higher priority for your packaging needs.

Table of Comparison

| Feature | Counter Pressure Filling | Vacuum Filling |

|---|---|---|

| Filling Method | Injects beverage under pressure to minimize oxygen incorporation | Removes air via vacuum before filling, reducing oxidation |

| Ideal For | Carbonated drinks (beer, soda) | Non-carbonated beverages (juice, water) |

| Oxygen Exposure | Minimal oxygen pickup during filling | Low oxygen exposure, but higher than counter pressure |

| Filling Speed | Moderate to high speed with precision | High speed but risk of foaming with carbonated drinks |

| Equipment Complexity | More complex, requires precise sealing and pressure control | Less complex, simpler vacuum system |

| Application | Used in breweries and soda bottling lines | Used for water, juice, and non-carbonated beverage bottling |

Introduction to Liquid Filling Technologies

Counter pressure filling utilizes pressurized gas to balance bottle pressure during carbonation-sensitive liquid filling, minimizing foam and preserving carbonation levels. Vacuum filling creates a reduced pressure environment inside the container, allowing liquid to flow in smoothly without excessive foaming. Both technologies play crucial roles in the beverage industry, optimizing fill accuracy and product quality based on liquid type and container requirements.

What is Counter Pressure Filling?

Counter pressure filling is a specialized bottling process designed to handle carbonated beverages by pressurizing containers with inert gas before filling to prevent carbonation loss and foam formation. This method ensures product integrity by equalizing the pressure inside the bottle with the surrounding environment, preserving carbonation levels and extending shelf life. It is widely used in the beverage industry for filling liquids such as beer, sparkling wine, and soft drinks under controlled pressure conditions.

What is Vacuum Filling?

Vacuum filling is a specialized process used to fill containers by creating a vacuum that removes air, allowing liquid or semi-liquid products to flow evenly and precisely into packaging. This technique minimizes oxidation, preserves product integrity, and is ideal for sensitive substances such as beverages, dairy, or cosmetics. You benefit from increased product consistency and reduced contamination risks through vacuum filling.

Key Differences Between Counter Pressure and Vacuum Filling

Counter pressure filling uses pressurized gas to force carbonated beverages into bottles, preserving carbonation and preventing foaming, while vacuum filling removes air from the bottle to minimize oxygen exposure and oxidation. The key difference lies in the carbonation control: counter pressure filling maintains high carbonation levels, ideal for beer and sparkling drinks, whereas vacuum filling excels in non-carbonated beverages requiring shelf stability. Your choice depends on the beverage type and desired preservation method, ensuring optimal quality and freshness.

Advantages of Counter Pressure Filling

Counter pressure filling offers significant advantages for preserving beverage quality by minimizing oxidation and maintaining carbonation levels during the bottling process. This method uses pressurized gas to equalize bottle pressure before filling, reducing foam formation and product waste compared to vacuum filling. Your bottling operation benefits from improved shelf life and consistent product quality, especially for carbonated drinks like beer and sparkling water.

Advantages of Vacuum Filling

Vacuum filling offers precise liquid control, minimizing foam formation and reducing product waste during bottling processes. It is ideal for carbonated beverages and sensitive liquids, as it preserves carbonation and maintains product integrity by preventing oxidation. This method enhances production efficiency by enabling faster filling speeds and easier handling of various container shapes and sizes compared to counter pressure filling.

Applications Suitable for Counter Pressure Filling

Counter pressure filling is ideal for carbonated beverages like beer, soda, and sparkling water, preserving carbonation and preventing foaming during the filling process. This method suits industries requiring sterile, oxygen-free environments, such as breweries and beverage manufacturers targeting high-quality product consistency. It also supports filling in glass and PET bottles, ensuring minimal loss of carbonation and maintaining product freshness.

Applications Suitable for Vacuum Filling

Vacuum filling is ideal for packaging delicate liquids such as juices, dairy products, and carbonated beverages because it minimizes oxidation and preserves flavor integrity. This method suits heat-sensitive products and those prone to foaming, ensuring accurate fill levels and reducing product waste. Industries like food and beverage, pharmaceuticals, and cosmetics often rely on vacuum filling for maintaining product quality and extending shelf life.

Factors to Consider When Choosing a Filling Method

Choosing between counter pressure filling and vacuum filling depends on factors such as the type of liquid, carbonation level, and container material. Counter pressure filling is ideal for carbonated beverages, preserving carbonation by equalizing container pressure, while vacuum filling suits still liquids by minimizing oxidation. Evaluating your product's sensitivity to oxygen exposure, production speed requirements, and equipment cost will help determine the optimal filling method.

Conclusion: Which Filling Technique Is Best for Your Product?

Counter pressure filling is ideal for carbonated beverages, maintaining carbonation by equalizing pressure during filling, ensuring product integrity for sparkling wines and sodas. Vacuum filling suits still liquids by reducing pressure to draw the product into the container gently, minimizing foaming and oxidation for juices and oils. Selecting the best filling technique depends on product characteristics, carbonation level, and desired shelf life to optimize quality and efficiency.

Counter pressure filling vs vacuum filling Infographic

libmatt.com

libmatt.com