Foam stability refers to the ability of foam to maintain its structure and resist collapse over time, while foam retention measures how long the foam persists in a system before breaking down. Understanding the difference helps you optimize processes in industries like detergents or firefighting where both foam longevity and performance are crucial.

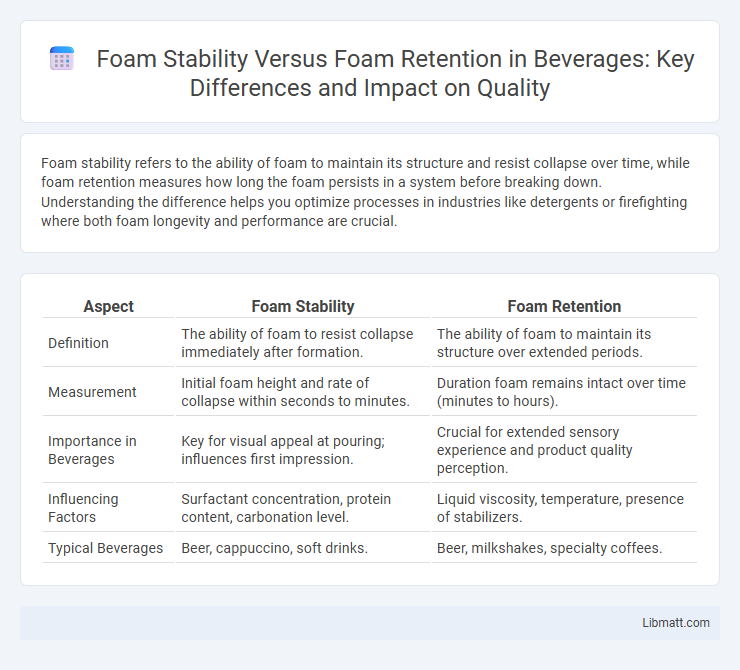

Table of Comparison

| Aspect | Foam Stability | Foam Retention |

|---|---|---|

| Definition | The ability of foam to resist collapse immediately after formation. | The ability of foam to maintain its structure over extended periods. |

| Measurement | Initial foam height and rate of collapse within seconds to minutes. | Duration foam remains intact over time (minutes to hours). |

| Importance in Beverages | Key for visual appeal at pouring; influences first impression. | Crucial for extended sensory experience and product quality perception. |

| Influencing Factors | Surfactant concentration, protein content, carbonation level. | Liquid viscosity, temperature, presence of stabilizers. |

| Typical Beverages | Beer, cappuccino, soft drinks. | Beer, milkshakes, specialty coffees. |

Introduction to Foam Stability and Foam Retention

Foam stability refers to the ability of bubbles within a foam to resist rupture over time, influenced by factors such as liquid viscosity, surface tension, and surfactant concentration. Foam retention, on the other hand, measures how long the foam mass remains intact on a surface or within a system before collapsing or draining. Understanding the distinction between foam stability and foam retention is crucial for optimizing foam performance in applications like firefighting, food processing, and cosmetic formulations.

Defining Foam Stability

Foam stability refers to the ability of foam bubbles to resist bursting or coalescence over time, maintaining the foam structure against factors like drainage, coarsening, and film rupture. It is a key parameter measured by the lifetime of individual bubbles and the resistance of liquid films to thinning under various physical and chemical conditions. Foam retention, often confused with foam stability, specifically describes the capacity of foam to stay intact within a system, emphasizing the macroscopic persistence rather than microscopic bubble durability.

Defining Foam Retention

Foam retention refers to the ability of a foam to maintain its structure and volume over time under static conditions, distinguishing it from foam stability, which often considers dynamic factors like drainage and coalescence. Effective foam retention ensures that bubbles resist collapse, providing longer-lasting foam performance crucial in applications such as firefighting, food processing, and detergents. Understanding foam retention helps you optimize formulations to achieve sustained foam presence without rapid decay.

Key Differences Between Foam Stability and Retention

Foam stability refers to the ability of a foam to resist collapse or coalescence over time, while foam retention measures how long the foam persists in a given environment. Key differences lie in stability's focus on structural integrity and resistance to bubble merging, whereas retention emphasizes the foam's longevity and resistance to drainage or evaporation. Understanding these factors helps optimize foam performance in applications such as firefighting, cosmetics, and food processing.

Importance of Foam Stability in Industrial Applications

Foam stability is crucial in industrial applications where consistent foam performance affects product quality, such as in firefighting foams or food processing. Unlike foam retention, which measures how long foam remains, foam stability assesses the foam's resistance to collapse under various environmental conditions, directly impacting operational efficiency. Ensuring your foam has high stability minimizes downtime and material waste, optimizing overall process reliability.

Factors Influencing Foam Stability

Foam stability depends on factors like liquid viscosity, surfactant type, and bubble size, which affect the foam's ability to resist collapse over time. Foam retention measures how long foam persists, influenced by environmental conditions such as temperature, gas diffusion, and mechanical agitation. Your understanding of these factors can improve foam applications in industries like food processing, cosmetics, and firefighting.

Variables Affecting Foam Retention

Foam retention depends on variables such as liquid viscosity, surface tension, and the presence of surfactants, which collectively influence foam film thickness and drainage rate. Temperature and pH levels also affect foam stability by altering intermolecular forces and bubble coalescence. Understanding these parameters helps you optimize foam retention for applications in industries like firefighting, food processing, and cosmetics.

Methods of Measuring Foam Stability and Retention

Foam stability and foam retention are commonly measured using methods such as the Ross-Miles test, which evaluates foam collapse over time by observing bubble decay, and the Bartsch method, which quantifies foam volume reduction. Optical techniques like high-speed video analysis capture foam structure changes, providing detailed insights into stability dynamics. Your choice of method depends on the foam's application and required accuracy, with standardized tests ensuring consistent assessment of foam quality and performance.

Enhancing Foam Quality: Stability vs. Retention

Foam stability refers to the foam's ability to resist collapse over time, while foam retention measures the duration the foam remains intact under varying conditions. Enhancing foam quality requires optimizing both foam stability through surfactant selection and retention by controlling liquid drainage and bubble coalescence. High foam quality in applications such as firefighting and cosmetics depends on maintaining a balance between stable bubble structure and prolonged foam lifespan.

Practical Implications in Product Development

Foam stability measures the lifespan of foam bubbles, impacting product texture and sensory experience, while foam retention assesses how long foam maintains volume under stress. In product development, optimizing foam stability ensures consistent performance during shelf life, and enhancing foam retention improves consumer satisfaction by maintaining foam appearance and functionality. Balancing both factors is critical in industries like cosmetics, food, and detergents to achieve desired product efficacy and appeal.

Foam stability vs foam retention Infographic

libmatt.com

libmatt.com