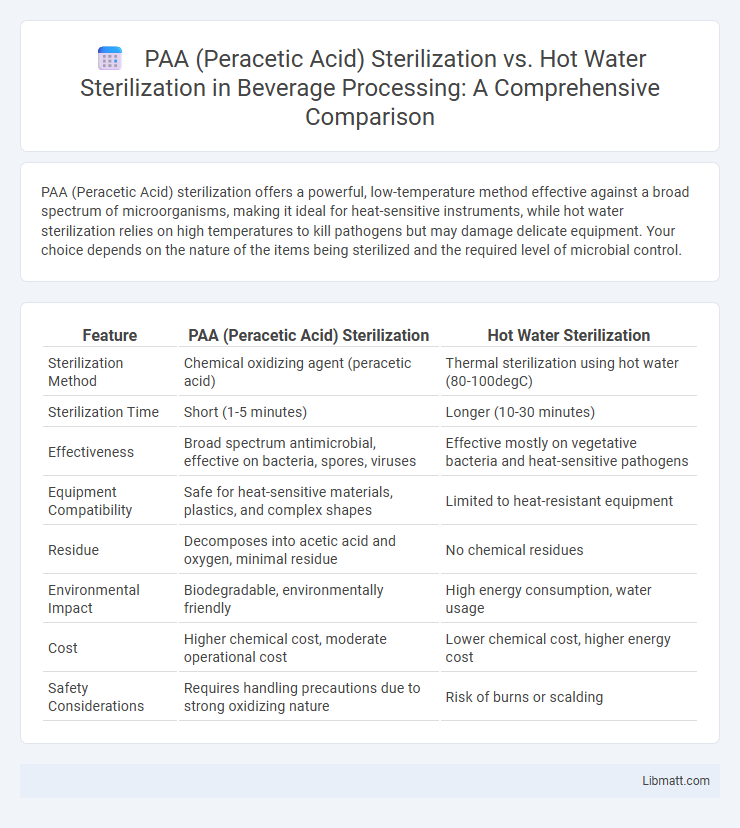

PAA (Peracetic Acid) sterilization offers a powerful, low-temperature method effective against a broad spectrum of microorganisms, making it ideal for heat-sensitive instruments, while hot water sterilization relies on high temperatures to kill pathogens but may damage delicate equipment. Your choice depends on the nature of the items being sterilized and the required level of microbial control.

Table of Comparison

| Feature | PAA (Peracetic Acid) Sterilization | Hot Water Sterilization |

|---|---|---|

| Sterilization Method | Chemical oxidizing agent (peracetic acid) | Thermal sterilization using hot water (80-100degC) |

| Sterilization Time | Short (1-5 minutes) | Longer (10-30 minutes) |

| Effectiveness | Broad spectrum antimicrobial, effective on bacteria, spores, viruses | Effective mostly on vegetative bacteria and heat-sensitive pathogens |

| Equipment Compatibility | Safe for heat-sensitive materials, plastics, and complex shapes | Limited to heat-resistant equipment |

| Residue | Decomposes into acetic acid and oxygen, minimal residue | No chemical residues |

| Environmental Impact | Biodegradable, environmentally friendly | High energy consumption, water usage |

| Cost | Higher chemical cost, moderate operational cost | Lower chemical cost, higher energy cost |

| Safety Considerations | Requires handling precautions due to strong oxidizing nature | Risk of burns or scalding |

Introduction to Sterilization Methods

PAA (Peracetic Acid) sterilization is a chemical method using a potent oxidizing agent effective against a broad spectrum of microorganisms, including spores, viruses, and bacteria. Hot water sterilization relies on high temperatures, typically between 80degC and 100degC, to denature proteins and eliminate pathogens effectively. Your choice between PAA and hot water sterilization depends on material compatibility, processing time, and the specific microbial load to be controlled.

What is Peracetic Acid (PAA) Sterilization?

Peracetic Acid (PAA) sterilization is a low-temperature chemical process that uses a potent oxidizing agent composed of acetic acid and hydrogen peroxide to eliminate bacteria, viruses, spores, and fungi on medical instruments. This method is highly effective for heat-sensitive devices as it achieves rapid sterilization cycles without compromising material integrity. Unlike hot water sterilization, which relies on high temperatures and moisture, PAA sterilization offers broad-spectrum antimicrobial activity with minimal environmental impact due to its biodegradability.

Overview of Hot Water Sterilization

Hot water sterilization uses temperatures typically between 80degC and 100degC to eliminate microorganisms through protein denaturation and enzyme inactivation. This method is widely applied in healthcare and laboratory settings due to its simplicity and effectiveness against bacteria, viruses, and fungi. You can rely on hot water sterilization for routine cleaning processes, but it may not be suitable for heat-sensitive instruments or materials.

Mechanisms of Action: PAA vs. Hot Water

Peracetic acid (PAA) sterilization disrupts microbial cell walls and denatures proteins through strong oxidative mechanisms, effectively deactivating spores, bacteria, and viruses at low temperatures. Hot water sterilization relies on the application of moist heat, coagulating microbial proteins and causing irreversible damage to cell components, but often requires higher temperatures and longer exposure times. Your choice between PAA and hot water sterilization depends on the materials' heat sensitivity and the specific microbial load targeted, with PAA offering rapid, low-temperature efficacy.

Spectrum of Microbial Efficacy

Peracetic acid (PAA) sterilization exhibits a broad-spectrum microbial efficacy, effectively inactivating bacteria, viruses, fungi, spores, and mycobacteria within minutes. Hot water sterilization primarily targets vegetative microorganisms and some spores but is less effective against heat-resistant pathogens and viruses without prolonged exposure. The reactive oxidizing properties of PAA disrupt cell walls and denature proteins, enabling rapid and comprehensive sterilization, outperforming thermal methods in microbial spectrum coverage.

Equipment Compatibility and Material Impact

PAA (Peracetic Acid) sterilization is highly compatible with a wide range of equipment materials including stainless steel, plastics, and glass, causing minimal corrosion or material degradation compared to hot water sterilization. Hot water sterilization often exposes equipment to high temperatures that can warp or weaken plastics and rubber components over time, reducing their lifespan. Choosing PAA sterilization can help preserve your equipment's integrity while maintaining effective sterilization performance.

Safety and Environmental Considerations

Peracetic acid (PAA) sterilization offers significant safety advantages due to its low toxicity and rapid biodegradability, minimizing harmful residues and exposure risks compared to chemical disinfectants. Hot water sterilization requires high temperatures that pose burn hazards and consume substantial energy, increasing environmental impact via higher carbon emissions. PAA decomposes into environmentally benign byproducts like acetic acid and oxygen, whereas hot water methods rely heavily on continuous energy input, making PAA a more sustainable and eco-friendly sterilization choice.

Operational Efficiency and Cycle Time

Peracetic Acid (PAA) sterilization offers superior operational efficiency with significantly shorter cycle times compared to hot water sterilization, often completing processes in under 30 minutes versus the hour or more required for hot water methods. PAA's rapid biocidal action reduces downtime and increases throughput, making it ideal for high-demand environments. Your sterilization workflow benefits from faster turnaround without compromising microbial kill efficacy.

Cost Comparison: PAA vs. Hot Water

Peracetic Acid (PAA) sterilization typically incurs higher initial equipment costs but offers lower energy expenses compared to hot water sterilization, which demands continuous high-temperature water heating. Your overall operational costs may be reduced with PAA due to shorter cycle times and less water consumption, while hot water sterilization involves ongoing utility fees and maintenance for heating systems. Choosing between these methods depends on balancing upfront investment against long-term energy and resource savings.

Choosing the Right Sterilization Method

Selecting the appropriate sterilization method depends on factors such as material compatibility, sterilization efficacy, and processing time. PAA (Peracetic Acid) sterilization offers broad-spectrum antimicrobial activity at low temperatures, making it suitable for heat-sensitive medical instruments and materials. Hot water sterilization requires higher temperatures, which may compromise delicate devices but provides rapid and effective microbial reduction for heat-resistant items.

PAA (Peracetic Acid) sterilization vs hot water sterilization Infographic

libmatt.com

libmatt.com