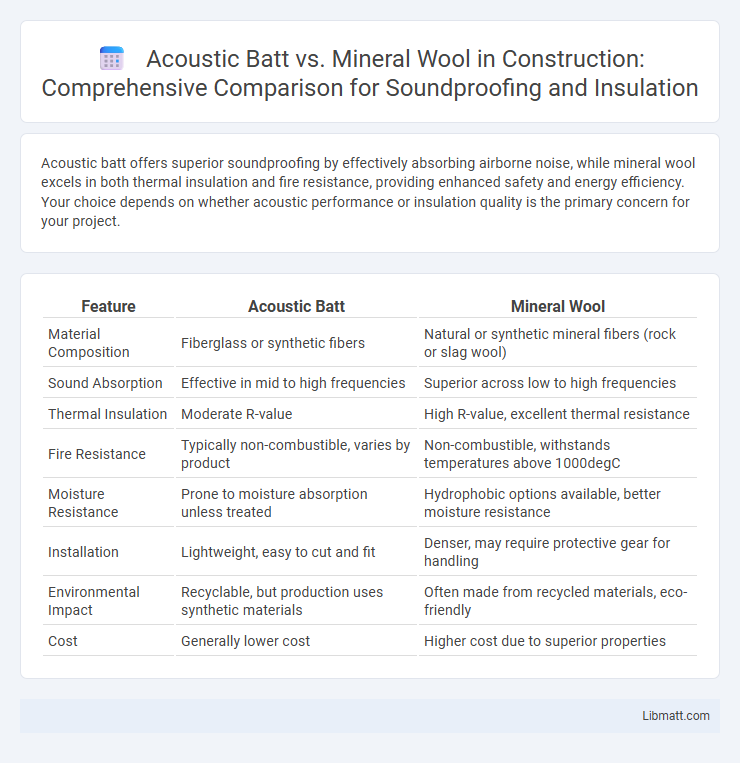

Acoustic batt offers superior soundproofing by effectively absorbing airborne noise, while mineral wool excels in both thermal insulation and fire resistance, providing enhanced safety and energy efficiency. Your choice depends on whether acoustic performance or insulation quality is the primary concern for your project.

Table of Comparison

| Feature | Acoustic Batt | Mineral Wool |

|---|---|---|

| Material Composition | Fiberglass or synthetic fibers | Natural or synthetic mineral fibers (rock or slag wool) |

| Sound Absorption | Effective in mid to high frequencies | Superior across low to high frequencies |

| Thermal Insulation | Moderate R-value | High R-value, excellent thermal resistance |

| Fire Resistance | Typically non-combustible, varies by product | Non-combustible, withstands temperatures above 1000degC |

| Moisture Resistance | Prone to moisture absorption unless treated | Hydrophobic options available, better moisture resistance |

| Installation | Lightweight, easy to cut and fit | Denser, may require protective gear for handling |

| Environmental Impact | Recyclable, but production uses synthetic materials | Often made from recycled materials, eco-friendly |

| Cost | Generally lower cost | Higher cost due to superior properties |

Introduction to Acoustic Batt and Mineral Wool

Acoustic batt is a soundproofing material made from fiberglass or polyester fibers designed to reduce noise transmission and enhance sound insulation in residential and commercial buildings. Mineral wool, also known as rock wool or stone wool, is produced from molten basalt or slag spun into fibrous form, offering superior thermal insulation, fire resistance, and acoustic performance. Your choice between acoustic batt and mineral wool depends on factors such as installation environment, desired soundproofing level, and thermal insulation needs.

Key Differences Between Acoustic Batt and Mineral Wool

Acoustic batt and mineral wool differ primarily in composition, with acoustic batt typically made from fiberglass and mineral wool derived from natural rock or slag. Mineral wool offers superior fire resistance and sound absorption across a broader frequency range compared to acoustic batt. Acoustic batt is lighter and easier to handle, making it suitable for residential soundproofing, while mineral wool is preferred in commercial and industrial applications due to its thermal insulation and moisture resistance properties.

Composition and Materials Used

Acoustic batt insulation typically consists of fiberglass or polyester fibers designed to minimize sound transmission by trapping airborne noise within its dense, fibrous structure. Mineral wool, also known as rock wool or stone wool, is made from natural or recycled stone and slag, offering superior fire resistance and sound absorption due to its rigid, porous composition. The mineral wool's inorganic base material differentiates it from acoustic batt's organic fibers, impacting performance, durability, and environmental sustainability.

Sound Insulation Performance

Acoustic batt insulation typically offers higher sound absorption with a Noise Reduction Coefficient (NRC) ranging from 0.70 to 0.90, effectively reducing airborne noise in interior walls and ceilings. Mineral wool provides superior sound insulation through its higher density and rigidity, delivering a Sound Transmission Class (STC) rating often between 50 and 60, which excels at blocking sound transmission between rooms. Both materials improve acoustic comfort, but mineral wool is generally preferred for applications requiring enhanced soundproofing due to its combination of density, fire resistance, and moisture durability.

Thermal Insulation Properties

Acoustic batt and mineral wool both provide excellent thermal insulation, but mineral wool typically offers higher R-values, enhancing your home's energy efficiency. Mineral wool's dense structure resists heat transfer more effectively, making it ideal for maintaining indoor temperatures and reducing heating and cooling costs. Acoustic batt, while beneficial for soundproofing, may offer slightly lower thermal performance compared to mineral wool, depending on thickness and material composition.

Fire Resistance and Safety

Acoustic batt and mineral wool both offer excellent fire resistance, but mineral wool stands out due to its non-combustible nature and ability to withstand temperatures exceeding 1,800degF (1,000degC), making it ideal for fire safety applications. Acoustic batt, often made from fiberglass or polyester, provides some fire resistance but typically has lower melting points and may emit toxic fumes when exposed to high heat. Mineral wool's superior fire-resistant properties contribute to safer building environments by preventing flame spread and enhancing structural integrity during fires.

Installation Process and Flexibility

Acoustic batt insulation offers straightforward installation with pre-cut panels that fit easily between standard stud and joist spacing, making it ideal for quick application in residential and commercial projects. Mineral wool provides greater flexibility due to its denser, firmer texture, allowing it to be cut and shaped to fit irregular spaces and around pipes or wiring, enhancing acoustic performance in complex areas. Both materials require minimal special tools, but mineral wool's fire-resistant properties also make it suitable for installations where safety and durability are critical.

Durability and Lifespan

Acoustic batt insulation typically offers moderate durability with a lifespan of around 20 to 30 years, depending on environmental conditions and installation quality. Mineral wool insulation is highly durable, resistant to moisture, fire, and pests, often lasting 50 years or more without significant degradation. Mineral wool's enhanced resistance to mold and compression contributes to its extended lifespan compared to acoustic batts.

Cost Comparison and Affordability

Acoustic batt insulation typically costs less per square foot than mineral wool, making it a more budget-friendly option for large-scale projects. Mineral wool offers superior soundproofing and fire resistance but comes at a higher price point due to its manufacturing process and raw materials. Homeowners and contractors should weigh upfront costs against long-term benefits like durability and noise reduction efficiency when choosing between these materials.

Choosing the Right Insulation for Your Needs

Acoustic batts offer superior sound absorption, making them ideal for reducing noise in residential or commercial spaces. Mineral wool insulation provides excellent thermal resistance along with fire and moisture resistance, enhancing energy efficiency and safety. Your choice depends on whether your priority is soundproofing or combined thermal performance with added durability.

Acoustic batt vs Mineral wool Infographic

libmatt.com

libmatt.com