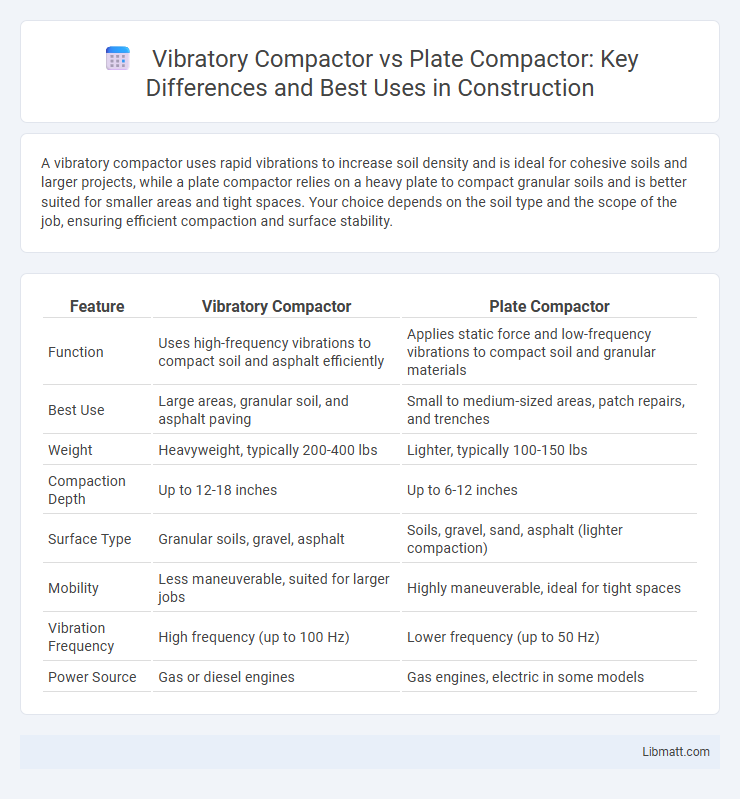

A vibratory compactor uses rapid vibrations to increase soil density and is ideal for cohesive soils and larger projects, while a plate compactor relies on a heavy plate to compact granular soils and is better suited for smaller areas and tight spaces. Your choice depends on the soil type and the scope of the job, ensuring efficient compaction and surface stability.

Table of Comparison

| Feature | Vibratory Compactor | Plate Compactor |

|---|---|---|

| Function | Uses high-frequency vibrations to compact soil and asphalt efficiently | Applies static force and low-frequency vibrations to compact soil and granular materials |

| Best Use | Large areas, granular soil, and asphalt paving | Small to medium-sized areas, patch repairs, and trenches |

| Weight | Heavyweight, typically 200-400 lbs | Lighter, typically 100-150 lbs |

| Compaction Depth | Up to 12-18 inches | Up to 6-12 inches |

| Surface Type | Granular soils, gravel, asphalt | Soils, gravel, sand, asphalt (lighter compaction) |

| Mobility | Less maneuverable, suited for larger jobs | Highly maneuverable, ideal for tight spaces |

| Vibration Frequency | High frequency (up to 100 Hz) | Lower frequency (up to 50 Hz) |

| Power Source | Gas or diesel engines | Gas engines, electric in some models |

Overview of Vibratory and Plate Compactors

Vibratory compactors utilize a combination of vibration and static weight to achieve deep soil and asphalt compaction, making them suitable for large-scale construction projects. Plate compactors, also known as vibratory plate compactors, feature a flat, heavy plate that compacts surface layers of soil, gravel, or asphalt efficiently in confined or smaller areas. Both types optimize ground stability, but vibratory compactors offer deeper compaction while plate compactors excel in maneuverability and ease of use for surface compaction tasks.

Key Differences Between Vibratory and Plate Compactors

Vibratory compactors use a combination of static weight and high-frequency vibrations to compact soil and asphalt, making them ideal for large-scale projects requiring deep compaction. Plate compactors rely primarily on the weight of the plate and a low-frequency, high-amplitude vibration to compact granular soil and asphalt on smaller, confined areas. Understanding these key differences helps you select the right compactor based on project size, soil type, and compaction depth requirements.

Working Mechanism of Vibratory Compactors

Vibratory compactors operate using a combination of static weight and rapid, vertical vibrations generated by an internal eccentric shaft to compact soil effectively. The vibrations reduce soil particle friction, allowing particles to settle into a denser configuration, which enhances load-bearing capacity and stability. Understanding this working mechanism helps you select the right equipment for efficient soil compaction in construction projects.

How Plate Compactors Operate

Plate compactors operate by using a heavy steel plate that vibrates rapidly to compress soil, gravel, or asphalt surfaces. The vibration generated by an engine-driven eccentric weight increases compaction force, making surfaces more stable and dense. Your choice of plate compactor depends on factors such as soil type, project size, and required compaction depth.

Applications: When to Use Vibratory Compactors

Vibratory compactors excel in applications requiring deep soil compaction, such as granular and crushed stone bases for road construction, large foundation pads, and large-scale earthworks. Your choice to use a vibratory compactor is ideal when working on cohesive soils and thick soil layers, ensuring uniform density and improved load-bearing capacity. These machines are particularly effective in dense, heavy-duty projects where greater compaction force and penetration depth are essential.

Applications: Best Uses for Plate Compactors

Plate compactors are ideal for compacting granular soils, asphalt, and gravel in small to medium-sized construction projects such as driveways, sidewalks, and patios. Their flat plate design delivers consistent compaction on confined areas, making them perfect for landscaping and road repair tasks where surface smoothness is crucial. Your choice of a plate compactor ensures efficient soil stabilization and surface preparation for layering materials.

Performance Comparison: Efficiency and Compaction Depth

Vibratory compactors deliver higher efficiency through rapid, high-frequency vibrations that enable deeper soil penetration, often reaching compaction depths of up to 24 inches. Plate compactors typically achieve shallower compaction depths, usually around 6 to 12 inches, making them suitable for surface-level tasks with moderate efficiency. The superior vibration mechanism in vibratory compactors enhances soil density and uniformity faster than the more limited amplitude vibrations of plate compactors.

Cost Comparison: Price and Maintenance Considerations

Vibratory compactors generally come with a higher initial purchase price than plate compactors due to their enhanced engine power and advanced vibration technology. Maintenance costs for vibratory compactors can also be higher, as they require more frequent servicing of complex components like exciter units, whereas plate compactors tend to have simpler mechanics and lower routine upkeep expenses. Your choice should consider both upfront investment and long-term maintenance to ensure cost-effectiveness for your construction projects.

User Experience: Ease of Operation and Safety

Vibratory compactors offer smoother operation with less vibration felt by the user, reducing fatigue and increasing safety during prolonged use. Plate compactors are generally lighter and easier to maneuver in tight spaces, but may transmit more vibration to your hands, potentially causing discomfort. Choosing the right compactor depends on balancing ease of operation with safety considerations specific to your project's demands.

Choosing the Right Compactor for Your Project

Vibratory compactors deliver deep soil compaction through high-frequency vibrations, making them ideal for cohesive soils and large areas, while plate compactors focus on surface compaction with a smaller, flat vibrating plate, best suited for granular soils and confined spaces. Your project's soil type, area size, and accessibility dictate the most effective choice; for thick, cohesive soil layers, a vibratory compactor ensures thorough density, whereas plate compactors excel in compacting asphalt, sand, or gravel in tight spots. Assessing these factors helps optimize ground stability, reduce future settling, and improve project durability.

Vibratory compactor vs plate compactor Infographic

libmatt.com

libmatt.com