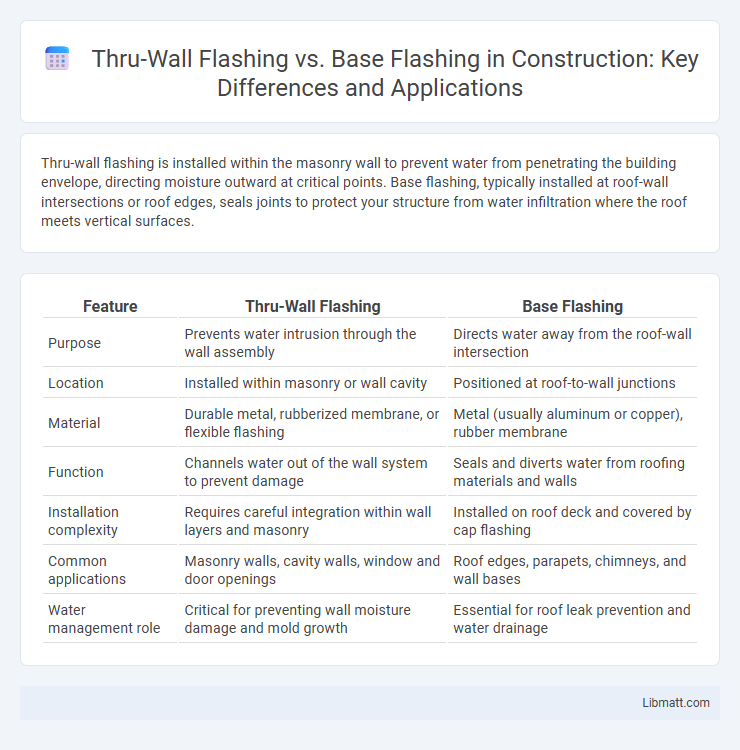

Thru-wall flashing is installed within the masonry wall to prevent water from penetrating the building envelope, directing moisture outward at critical points. Base flashing, typically installed at roof-wall intersections or roof edges, seals joints to protect your structure from water infiltration where the roof meets vertical surfaces.

Table of Comparison

| Feature | Thru-Wall Flashing | Base Flashing |

|---|---|---|

| Purpose | Prevents water intrusion through the wall assembly | Directs water away from the roof-wall intersection |

| Location | Installed within masonry or wall cavity | Positioned at roof-to-wall junctions |

| Material | Durable metal, rubberized membrane, or flexible flashing | Metal (usually aluminum or copper), rubber membrane |

| Function | Channels water out of the wall system to prevent damage | Seals and diverts water from roofing materials and walls |

| Installation complexity | Requires careful integration within wall layers and masonry | Installed on roof deck and covered by cap flashing |

| Common applications | Masonry walls, cavity walls, window and door openings | Roof edges, parapets, chimneys, and wall bases |

| Water management role | Critical for preventing wall moisture damage and mold growth | Essential for roof leak prevention and water drainage |

Introduction to Flashing in Construction

Flashing in construction is essential for directing water away from critical areas to prevent moisture intrusion and structural damage. Thru-wall flashing is installed within the wall assembly, bridging the gap between exterior cladding and the building structure to manage water that penetrates the facade. Base flashing is positioned at the junction of a roof and vertical surfaces, providing a waterproof barrier where the roof meets walls or chimneys to protect your building from leaks.

Understanding Thru-Wall Flashing

Thru-wall flashing is a critical component in building construction designed to prevent water from penetrating exterior walls by directing moisture out of the wall assembly. Unlike base flashing, which is installed at the roof-to-wall intersection to protect the roof deck, thru-wall flashing is embedded within the wall to intercept water before it reaches the interior. Understanding thru-wall flashing ensures your building maintains structural integrity and prevents costly water damage over time.

What is Base Flashing?

Base flashing is a critical component in roofing systems designed to prevent water infiltration at roof-to-wall junctions by directing moisture away from these vulnerable areas. Typically made from metal such as aluminum or copper, base flashing works in conjunction with other roofing elements like the roofing membrane and counter flashing to create a watertight seal. Proper installation of base flashing is essential for maintaining roof integrity and preventing leaks that can lead to structural damage.

Key Differences Between Thru-Wall and Base Flashing

Thru-wall flashing is installed within the masonry wall system to prevent water from penetrating through the entire wall, directing moisture safely out of the wall cavity. Base flashing, typically found at the junction between the roof and wall or parapet, provides a waterproof barrier that redirects water away from the roof deck to prevent leaks. Understanding these key differences ensures your building envelope remains protected from water infiltration at critical transition points.

Materials Used in Thru-Wall and Base Flashing

Thru-wall flashing commonly uses corrosion-resistant metals like copper, aluminum, or stainless steel, paired with flexible materials such as rubberized asphalt to ensure waterproofing behind exterior walls. Base flashing typically combines metal flashing, often aluminum or galvanized steel, with a compatible roofing membrane or sealant to protect roof-wall junctions from water infiltration. Your choice of materials directly impacts the durability and effectiveness of both thru-wall and base flashing in preventing moisture damage.

Installation Processes: Thru-Wall vs Base Flashing

Thru-wall flashing installation requires embedding a waterproof barrier within the wall assembly, typically integrated during the construction phase to direct moisture out of the wall cavity. Base flashing is installed at the roof-to-wall intersection or foundation line, often placed beneath the roofing or siding material to prevent water intrusion at vulnerable joints. Understanding the specific installation method of your flashing type ensures effective moisture management and building envelope protection.

Performance and Durability Comparison

Thru-wall flashing offers superior performance by effectively directing water away from the wall assembly, reducing the risk of moisture intrusion and structural damage. Base flashing, while essential for sealing roof-to-wall intersections, typically endures higher exposure to weather elements, which can affect its long-term durability. Materials like copper or high-grade rubberized asphalt enhance the longevity of both types, with thru-wall flashing generally providing more reliable, long-lasting protection in masonry wall systems.

Common Applications in Building Envelope Design

Thru-wall flashing is commonly applied in masonry cavity walls to prevent water infiltration by directing moisture out through weep holes, crucial in brick veneer and stone veneer assemblies. Base flashing is typically used at the junction of a roof and a vertical wall or parapet, sealing the connection to prevent water penetration in roofing systems. Both flashings are essential in building envelope design to manage water drainage and protect structural components from moisture damage.

Cost Implications and Maintenance Needs

Thru-wall flashing typically involves higher initial costs due to its complex installation within the wall assembly, while base flashing is generally more affordable and easier to install at the roof-wall junction. Maintenance needs for thru-wall flashing can be more intensive because it is embedded and harder to inspect or repair without damaging the wall, unlike base flashing which is more accessible and allows for straightforward routine checks and repairs. Your choice impacts long-term expenses, as thru-wall flashing may reduce water intrusion more effectively but requires vigilant maintenance to prevent costly structural damage.

Choosing the Right Flashing for Your Project

Choosing the right flashing for your project depends on the specific application and exposure to water infiltration; thru-wall flashing is essential for directing moisture out of the wall assembly, especially in masonry veneers where water may penetrate behind the cladding. Base flashing is typically used at the transition between the roof and the wall to prevent water from entering at these vulnerable junctions, making it crucial for flashings that link with roofing systems. Understanding the location and type of flashing needed ensures effective moisture management and long-term durability of the building envelope.

Thru-wall flashing vs Base flashing Infographic

libmatt.com

libmatt.com