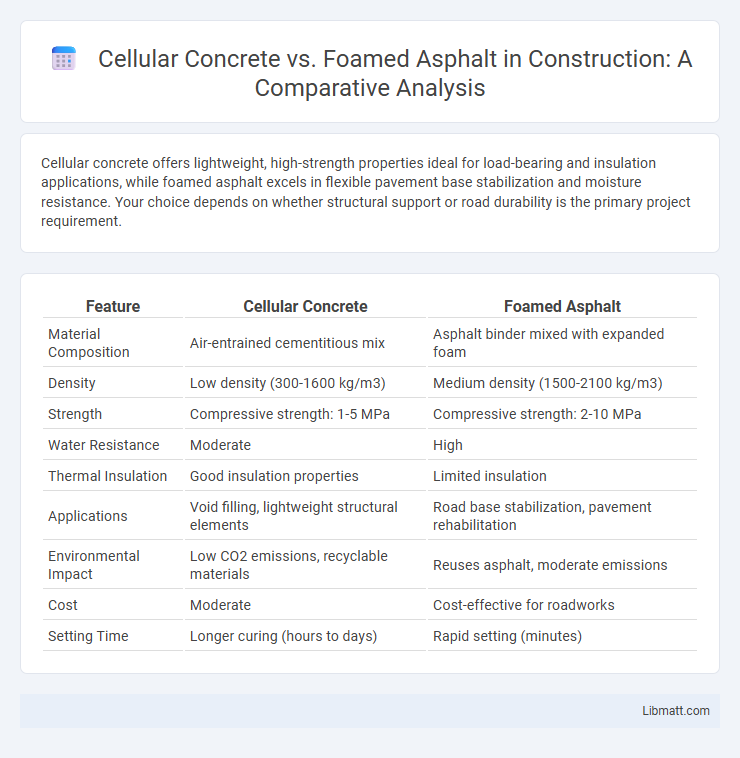

Cellular concrete offers lightweight, high-strength properties ideal for load-bearing and insulation applications, while foamed asphalt excels in flexible pavement base stabilization and moisture resistance. Your choice depends on whether structural support or road durability is the primary project requirement.

Table of Comparison

| Feature | Cellular Concrete | Foamed Asphalt |

|---|---|---|

| Material Composition | Air-entrained cementitious mix | Asphalt binder mixed with expanded foam |

| Density | Low density (300-1600 kg/m3) | Medium density (1500-2100 kg/m3) |

| Strength | Compressive strength: 1-5 MPa | Compressive strength: 2-10 MPa |

| Water Resistance | Moderate | High |

| Thermal Insulation | Good insulation properties | Limited insulation |

| Applications | Void filling, lightweight structural elements | Road base stabilization, pavement rehabilitation |

| Environmental Impact | Low CO2 emissions, recyclable materials | Reuses asphalt, moderate emissions |

| Cost | Moderate | Cost-effective for roadworks |

| Setting Time | Longer curing (hours to days) | Rapid setting (minutes) |

Introduction to Cellular Concrete and Foamed Asphalt

Cellular concrete is a lightweight, air-entrained material composed of cement, water, and foam, offering excellent thermal insulation and reduced density for construction applications. Foamed asphalt is a bituminous material created by injecting water and air into hot asphalt, producing a foam that improves soil stabilization and pavement base strength. Your choice between these materials depends on factors like load-bearing requirements, environmental conditions, and project-specific goals.

Composition and Production Methods

Cellular concrete is composed primarily of cement, water, and pre-formed foam, produced by mixing the foam with the cement slurry to create a lightweight, aerated material. Foamed asphalt consists of bitumen, water, and air, created by injecting water into hot asphalt to generate foam which is then mixed with granular materials for pavement stabilization. The production of cellular concrete involves controlled foam generation and cement slurry mixing, while foamed asphalt production relies on precise temperature control and foam expansion for optimal bitumen dispersion.

Key Physical Properties Comparison

Cellular concrete exhibits lower density values typically ranging from 400 to 1600 kg/m3, offering exceptional lightweight characteristics compared to foamed asphalt, which generally ranges from 1400 to 2000 kg/m3. The compressive strength of cellular concrete varies between 0.5 to 8 MPa, providing durability suitable for non-structural applications, whereas foamed asphalt boasts higher compressive strength, often between 1.5 to 7 MPa, making it suitable for flexible pavement layers. Thermal conductivity in cellular concrete is significantly lower, around 0.1 to 0.3 W/m*K, enhancing insulation properties, while foamed asphalt has slightly higher conductivity, usually between 0.5 and 0.75 W/m*K, affecting heat retention in road surfaces.

Strength and Durability Performance

Cellular concrete exhibits high compressive strength and excellent durability, making it suitable for load-bearing applications and long-term structural stability. Foamed asphalt provides flexible pavement performance with moderate strength and superior resistance to moisture-induced damage, enhancing durability in road constructions subject to dynamic loads. The choice between cellular concrete and foamed asphalt depends on the required strength and environmental conditions, with cellular concrete favoring static structural uses and foamed asphalt excelling in flexible, moisture-prone environments.

Insulation and Thermal Characteristics

Cellular concrete offers superior insulation due to its closed-cell structure, resulting in low thermal conductivity and enhanced energy efficiency for your building. Foamed asphalt provides moderate thermal insulation but excels in heat-resistant and flexible pavement applications, where thermal expansion and contraction are concerns. Choosing cellular concrete benefits thermal comfort and reduces heating and cooling costs in structures.

Applications in Construction Projects

Cellular concrete is widely used for lightweight fill, void filling, and thermal insulation in building foundations, retaining walls, and road embankments due to its excellent flowability and compressive strength. Foamed asphalt is primarily applied in road construction for stabilizing weak soils, improving pavement base courses, and recycling asphalt materials, enhancing durability and load-bearing capacity. Your choice between the two depends on project requirements such as load tolerance, environmental conditions, and specific construction objectives.

Cost Factors and Economic Advantages

Cellular concrete offers lower material costs and faster installation times compared to foamed asphalt, reducing overall labor expenses in construction projects. Foamed asphalt may lead to higher initial costs due to specialized equipment and longer curing times but provides superior strength and durability, potentially lowering maintenance expenses over time. Economic advantages of cellular concrete include lightweight properties that decrease transportation and foundation costs, while foamed asphalt's recyclability and environmental benefits can translate into long-term savings.

Environmental Impact and Sustainability

Cellular concrete offers significant environmental benefits due to its lightweight nature, which reduces material usage and lowers transportation emissions. Foamed asphalt contributes to sustainability by utilizing reclaimed asphalt pavement (RAP), minimizing waste and conserving natural aggregates. Your choice between these materials can influence the ecological footprint of construction projects, with cellular concrete excelling in resource efficiency and foamed asphalt promoting recycling and waste reduction.

Installation and Workability

Cellular concrete offers lightweight, flowable consistency that simplifies installation in complex geometries and confined spaces, promoting rapid curing and minimal shrinkage during workability. Foamed asphalt provides excellent compaction and flexibility with easy reheating capabilities, ideal for flexible pavement bases where moisture resistance is critical. Your choice depends on project requirements, as cellular concrete excels in insulation and load distribution, while foamed asphalt is better for flexible, durable road layers.

Choosing Between Cellular Concrete and Foamed Asphalt

Choosing between cellular concrete and foamed asphalt depends on factors such as load-bearing requirements, moisture sensitivity, and environmental conditions. Cellular concrete offers superior compressive strength and thermal insulation, making it ideal for structural applications and cold climates. Foamed asphalt provides excellent moisture resistance and flexibility, suitable for road bases and areas prone to water infiltration.

Cellular concrete vs foamed asphalt Infographic

libmatt.com

libmatt.com