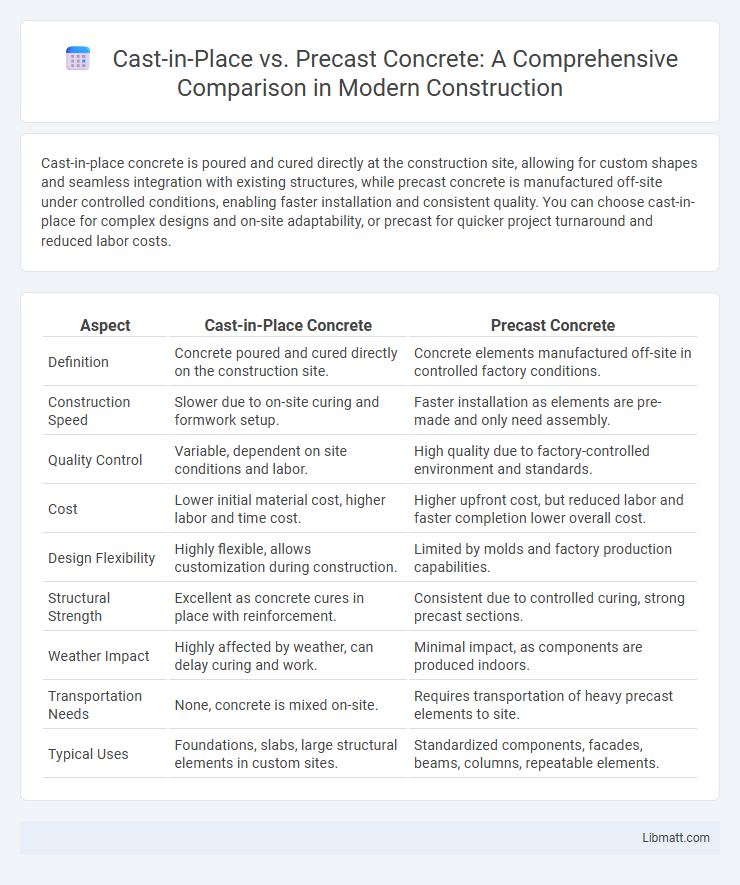

Cast-in-place concrete is poured and cured directly at the construction site, allowing for custom shapes and seamless integration with existing structures, while precast concrete is manufactured off-site under controlled conditions, enabling faster installation and consistent quality. You can choose cast-in-place for complex designs and on-site adaptability, or precast for quicker project turnaround and reduced labor costs.

Table of Comparison

| Aspect | Cast-in-Place Concrete | Precast Concrete |

|---|---|---|

| Definition | Concrete poured and cured directly on the construction site. | Concrete elements manufactured off-site in controlled factory conditions. |

| Construction Speed | Slower due to on-site curing and formwork setup. | Faster installation as elements are pre-made and only need assembly. |

| Quality Control | Variable, dependent on site conditions and labor. | High quality due to factory-controlled environment and standards. |

| Cost | Lower initial material cost, higher labor and time cost. | Higher upfront cost, but reduced labor and faster completion lower overall cost. |

| Design Flexibility | Highly flexible, allows customization during construction. | Limited by molds and factory production capabilities. |

| Structural Strength | Excellent as concrete cures in place with reinforcement. | Consistent due to controlled curing, strong precast sections. |

| Weather Impact | Highly affected by weather, can delay curing and work. | Minimal impact, as components are produced indoors. |

| Transportation Needs | None, concrete is mixed on-site. | Requires transportation of heavy precast elements to site. |

| Typical Uses | Foundations, slabs, large structural elements in custom sites. | Standardized components, facades, beams, columns, repeatable elements. |

Introduction to Cast-in-Place and Precast Concrete

Cast-in-place concrete is poured and cured directly at the construction site, offering flexibility in design and seamless integration with structural elements. Precast concrete components are manufactured in controlled factory environments, ensuring consistent quality and faster installation times on-site. Both methods are essential in modern construction, with cast-in-place suited for customized, monolithic structures and precast ideal for repetitive, large-scale projects.

Key Differences Between Cast-in-Place and Precast

Cast-in-place concrete is poured and cured directly on the construction site, allowing for greater flexibility in design and seamless integration with existing structures, while precast concrete is manufactured in controlled factory conditions, ensuring higher quality and faster installation. Cast-in-place typically involves longer construction timelines due to on-site curing, whereas precast components are produced simultaneously offsite, reducing onsite labor and construction time. Both methods differ significantly in terms of cost, durability, and suitability for complex architectural forms or large-scale repetitive projects.

Material Selection and Quality Control

Material selection for cast-in-place concrete involves choosing raw aggregates, cement, and admixtures tailored to on-site mixing, ensuring adaptability to project-specific conditions. Precast concrete requires factory-controlled raw materials and standardized mixes, promoting consistent quality and uniformity across components. Your decision influences quality control practices, as cast-in-place demands rigorous on-site monitoring, while precast benefits from precise factory inspections and automated curing processes.

Construction Speed and Scheduling

Cast-in-place concrete requires onsite curing time, often extending construction schedules especially in adverse weather conditions, while precast concrete components are manufactured offsite, allowing simultaneous site preparation and fabrication, thus significantly accelerating overall construction timelines. The use of precast elements reduces onsite labor requirements and minimizes delays caused by weather, enabling more predictable scheduling and faster project completion. Projects utilizing precast concrete benefit from streamlined logistics and repetitive manufacturing processes, contributing to improved efficiency and project time savings compared to traditional cast-in-place methods.

Cost Considerations and Budget Impact

Cast-in-place concrete typically incurs higher labor costs due to extended on-site work and formwork setup, which can increase overall project expenses. Precast concrete offers cost savings through factory-controlled production, reducing on-site construction time and minimizing weather-related delays, leading to more predictable budgeting. However, transportation and handling costs for precast elements can impact the budget depending on site accessibility and element size.

Design Flexibility and Architectural Features

Cast-in-place concrete offers superior design flexibility, enabling complex shapes, curves, and custom architectural features to be formed directly on-site, which accommodates unique project requirements. Precast concrete, while limited to factory-produced standard molds, ensures consistent quality and faster installation but may restrict the range of architectural expressions. Your choice between cast-in-place and precast will significantly impact the ability to achieve intricate design details and aesthetic customization.

Site Conditions and Project Logistics

Cast-in-place concrete adapts well to complex site conditions and irregular shapes, allowing for on-site adjustments despite longer curing times and increased labor requirements; it suits projects with ample space for formwork and staging. Precast concrete offers streamlined project logistics with factory-controlled quality and faster installation, ideal for sites with limited space or tight schedules, but demands precise planning for transportation and crane placement. Your choice depends on balancing site accessibility, project timeline, and logistical constraints.

Durability, Strength, and Performance

Cast-in-place concrete offers superior durability due to its monolithic construction, reducing joints and potential weak points, which enhances overall structural integrity. Precast concrete is manufactured under controlled conditions, resulting in higher strength consistency and quality control, ensuring reliable performance for specialized applications. Your choice between the two depends on project requirements for on-site adaptability versus factory precision in strength and long-term durability.

Sustainability and Environmental Impact

Cast-in-place concrete typically requires on-site mixing and curing, which can lead to higher energy consumption and CO2 emissions compared to precast concrete produced in controlled factory environments. Precast concrete elements often result in less waste, reduced transportation impacts due to modularity, and better quality control, contributing to greater sustainability and lower environmental footprints. Choosing precast or cast-in-place concrete depends on Your project's priorities for minimizing environmental impact and optimizing resource efficiency.

Best Applications for Cast-in-Place vs Precast

Cast-in-place concrete is ideal for custom, complex structural elements and foundations where on-site adjustments are necessary, providing seamless integration and enhanced strength. Precast concrete is best suited for repetitive, standardized components such as wall panels and beams, offering faster installation and superior quality control. Your choice depends on project scale, site conditions, and design flexibility requirements.

Cast-in-place vs Precast Infographic

libmatt.com

libmatt.com