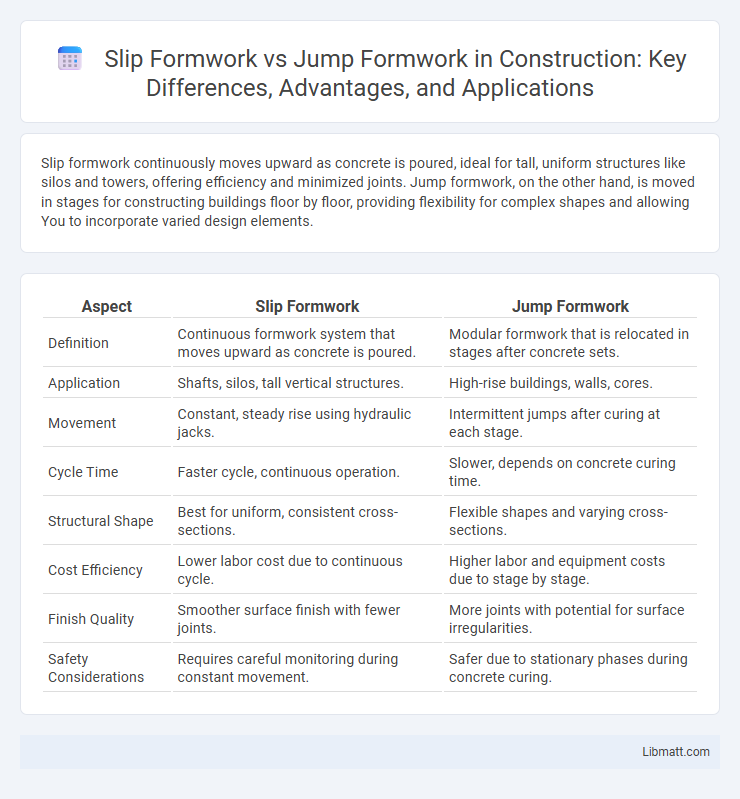

Slip formwork continuously moves upward as concrete is poured, ideal for tall, uniform structures like silos and towers, offering efficiency and minimized joints. Jump formwork, on the other hand, is moved in stages for constructing buildings floor by floor, providing flexibility for complex shapes and allowing You to incorporate varied design elements.

Table of Comparison

| Aspect | Slip Formwork | Jump Formwork |

|---|---|---|

| Definition | Continuous formwork system that moves upward as concrete is poured. | Modular formwork that is relocated in stages after concrete sets. |

| Application | Shafts, silos, tall vertical structures. | High-rise buildings, walls, cores. |

| Movement | Constant, steady rise using hydraulic jacks. | Intermittent jumps after curing at each stage. |

| Cycle Time | Faster cycle, continuous operation. | Slower, depends on concrete curing time. |

| Structural Shape | Best for uniform, consistent cross-sections. | Flexible shapes and varying cross-sections. |

| Cost Efficiency | Lower labor cost due to continuous cycle. | Higher labor and equipment costs due to stage by stage. |

| Finish Quality | Smoother surface finish with fewer joints. | More joints with potential for surface irregularities. |

| Safety Considerations | Requires careful monitoring during constant movement. | Safer due to stationary phases during concrete curing. |

Introduction to Slip Formwork and Jump Formwork

Slip formwork is a continuous concrete pouring technique used primarily for tall, vertical structures like silos and high-rise cores, where the formwork "slips" upwards steadily as the concrete sets. Jump formwork, in contrast, involves moving the entire formwork assembly in discrete stages, typically for building multi-story structures with substantial floor heights, ensuring stability and precision during each lift. Both methods optimize construction efficiency but differ significantly in movement mechanics and application scope for high-rise construction projects.

Key Principles of Slip Formwork

Slip formwork operates by continuously moving upward as concrete is poured, enabling an uninterrupted construction process for tall structures like silos and towers. The formwork moves at a controlled speed, synchronized with the concrete setting time to maintain structural integrity and surface smoothness. Your project benefits from increased efficiency and reduced construction joints when using slip formwork for vertical elements.

Key Principles of Jump Formwork

Jump formwork operates on a modular system that is lifted vertically using jacks after each concrete pour, enabling continuous construction of tall vertical structures like cores and walls. It relies on synchronized climbing mechanisms to maintain alignment and safety during repositioning, ensuring structural integrity and smooth workflow. The system incorporates integrated platforms and guardrails, enhancing worker safety while allowing for simultaneous operations at multiple levels.

Comparative Construction Processes

Slip formwork and jump formwork both enable efficient vertical concrete construction but differ in operation; slip formwork continuously moves upward with the concrete being poured simultaneously, ideal for tall, uniform structures like silos and towers. Jump formwork, on the other hand, operates in a cyclical process where the forms are lifted or "jumped" to the next level after concrete sets, commonly used for buildings and bridges requiring floor-by-floor construction. The continuous nature of slip formwork reduces cycle time but demands constant monitoring, while jump formwork offers flexibility for complex shapes and staggered timelines.

Efficiency and Speed: Slip vs Jump Formwork

Slip formwork offers superior efficiency and speed by allowing continuous concrete pouring, which significantly reduces construction time for tall structures like silos and towers. Jump formwork, while also effective, involves a cyclical process of dismantling and reassembling at higher levels, resulting in slower overall progress. Your choice between slip and jump formwork should consider project scale and timeline, with slip formwork being ideal for rapid, uninterrupted vertical construction.

Structural Applications and Suitability

Slip formwork is ideal for continuous vertical structures such as silos, chimneys, and tall walls due to its ability to move continuously as concrete is poured, enabling efficient construction of seamless, monolithic structures. Jump formwork is best suited for high-rise buildings and bridges where floor-by-floor construction is required, providing a stable platform that can be lifted in stages to accommodate repetitive structural components. Both systems enhance structural integrity, but slip formwork excels in uninterrupted vertical elements while jump formwork optimizes segmented, multi-story construction.

Material and Labor Requirements

Slip formwork requires continuous concrete pouring and uses lightweight steel or aluminum forms, minimizing labor intensity but demanding skilled operators for smooth, steady movement. Jump formwork employs modular steel or aluminum panels that are manually or mechanically raised in stages, necessitating more labor for assembly and adjustment at each level. Material costs for slip formwork are generally lower due to fewer components, while jump formwork involves higher expenses from multiple reusable panels and enhanced labor input.

Safety Considerations in Both Systems

Slip formwork enhances safety by providing continuous support as it moves steadily, minimizing gaps and reducing fall hazards for workers at height. Jump formwork involves periodic dismantling and reassembly, requiring stringent safety protocols to manage risks associated with temporary instability and manual handling. Both systems demand rigorous inspection, secure anchoring, and comprehensive worker training to ensure a safe construction environment.

Cost Implications and Economic Analysis

Slip formwork typically incurs lower labor costs due to its continuous pouring process, which reduces construction time and increases overall efficiency. Jump formwork demands higher initial investment in modular components but offers better adaptability for complex structures, potentially lowering long-term expenses through reuse. Evaluating your project's scale and timeline is essential for selecting the most cost-effective formwork system that balances upfront expenditures with operational savings.

Choosing the Right Formwork System

Choosing the right formwork system depends on project scale, speed requirements, and structural complexity. Slip formwork offers continuous, rapid concrete placement ideal for tall, repetitive structures like silos and towers, while jump formwork provides modular, reusable panels suitable for high-rise buildings with frequent changes in form shape. Understanding your construction timeline and structural needs ensures you select the most efficient, cost-effective system for your project.

Slip formwork vs jump formwork Infographic

libmatt.com

libmatt.com